New company launches Pork Sword and Scorpitrol®

Austin, TX (January 22, 2019) — Whether you’re blue collar or white collar, if you’re pro-Second Amendment you’re black collar.

We’re Black Collar Arms and we’re here to bring innovative and functional firearms products to market at a fair price. Black Collar’s founders have backgrounds in product design and development and extensive firearm experience. Our engineers are former and current competitive shooters in various disciplines with engineering degrees from MIT and other snooty, prestigious places they’d love to tell you all about.

As you may have noticed from some of our product names and our marketing, we like to have fun and we don’t take ourselves too seriously. What we do take extremely seriously is our customers and the quality and functionality of our products.

Black Collar Arms is located in Central Texas and is committed to manufacturing our components in the U.S. from U.S.-made raw materials and components.

Contact us any time at manservant@blackcollararms.com, visit us at www.BlackCollarArms.com, and find us on Instagram at @blackcollararms.

Announcing the Pork Sword Chassis

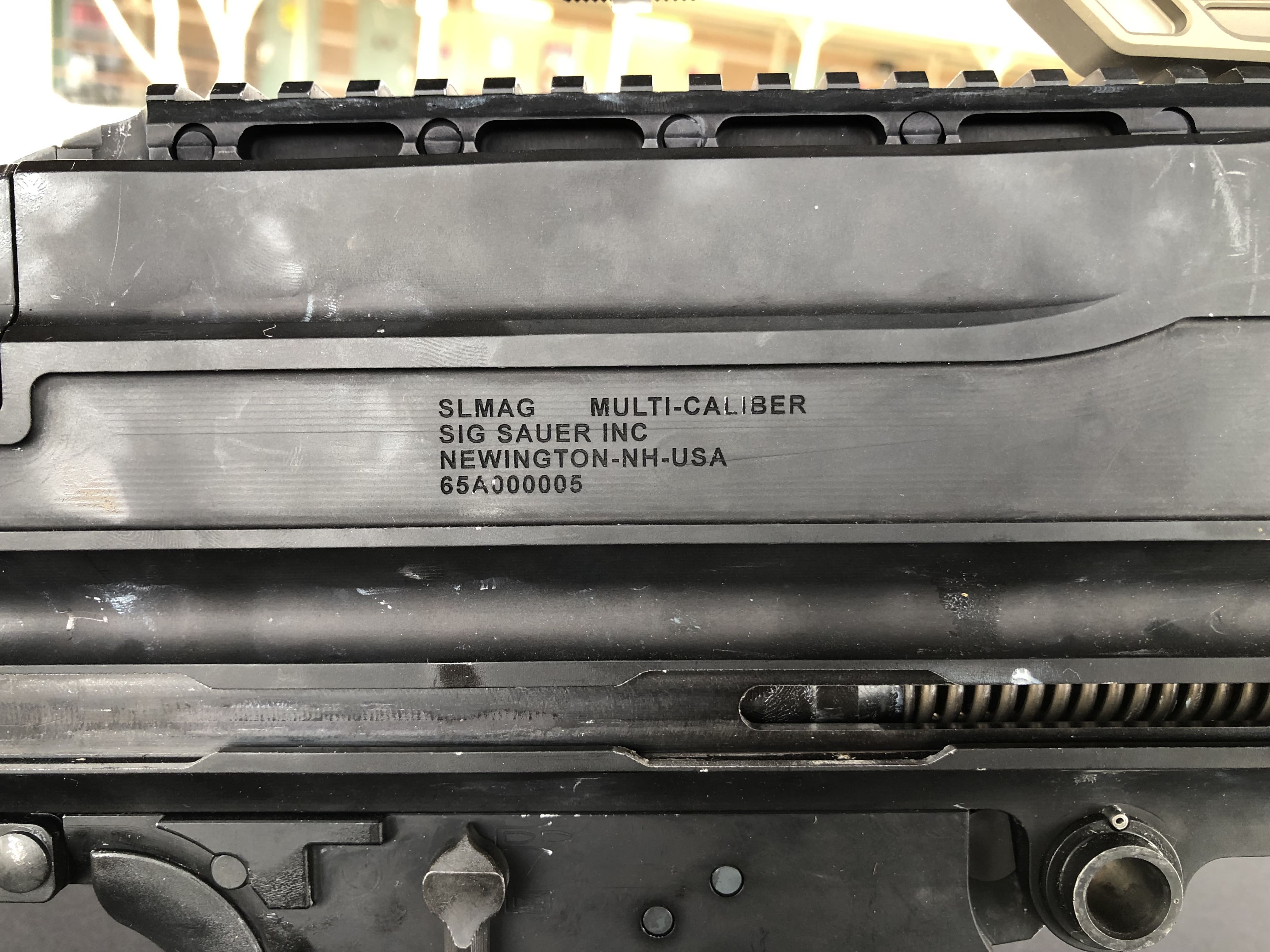

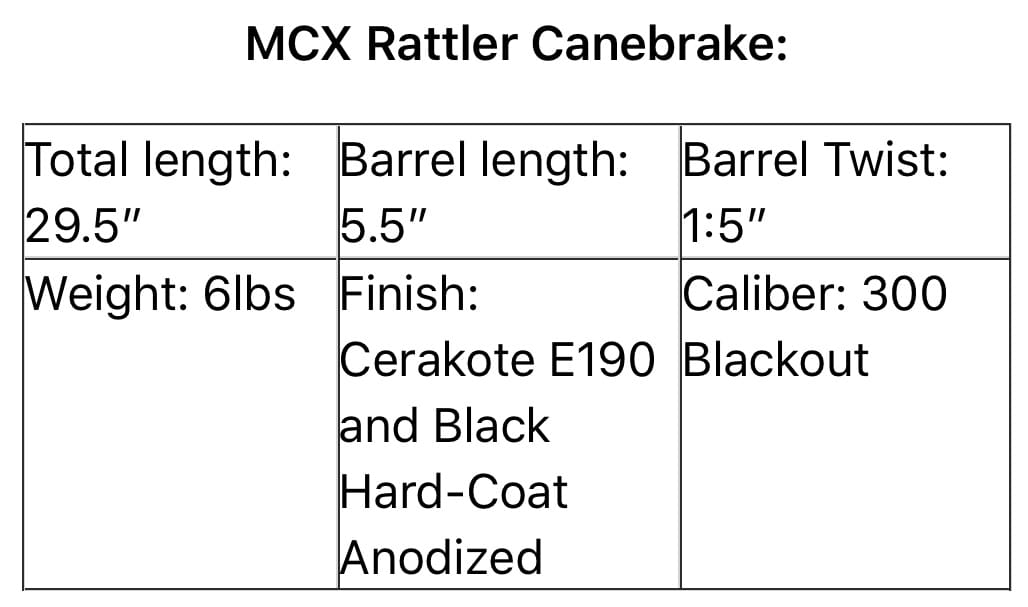

Weighing in at a scant 14.7 ounces, the Black Collar Arms Pork Sword is a minimalist, modular chassis compatible with left- or right-handed Remington 700 footprint short actions.

With a rear Picatinny rail, build yourself a pistol with a brace like the SB Tactical FS1913 or dust off that old R700 rifle and start a new, shoulder stock-equipped project today!

Ideal for hog hunting, general truck gun use, or just finding some fun on the shooting range, a Pork Sword Pistol suppresses wonderfully and puts rifle accuracy and capability in an extremely compact package.

Whether it’s the handy size, the additional handgun hunting seasons in some states, the ability to keep it loaded in a vehicle (hunting-related restrictions on loaded rifles don’t apply), the simplified ownership in some states as compared to a semi-auto pistol or rifle, how great of a suppressor host it is, or simply the cool and fun factor, a bolt-action pistol makes all sorts of sense.

The Black Collar Arms Pork Sword:

• 7075 Aluminum

• Type III Hard Coat Anodized as standard (Cerakote options available)

• Accepts most AR-15 pistol grips

• Accepts any M1913 Picatinny rail-compatible pistol stabilizing brace or shoulder stock

• Accepts AICS pattern, single-stack magazines

• Ambidextrous QD sling sockets front and rear

• Two front Picatinny rails for barrier stop, bipod, angled or vertical forward grip, and/or Black Collar Arms FARend or handguard adapter (2nd front Pic rail not seen on these prototypes)

• Uses standard, 1-inch AR-15 grip screws for the front and rear action screws and the grip (duh)

• 100% designed and manufactured in Texas from domestic aluminum

• MSRP: $299.99

Coming soon from Black Collar Arms for the Pork Sword:

• FARend — The Pork Sword Chassis’ integral front Pic rail is a bit close for a bipod. Mount it out farther with our FARend. That’s Forward Accessory Rod. Then the word “end” so it sounds like forend. Anyway, the FARend’s M-LOK® slots allow you to mount a bipod, angled or vertical forward grip, and/or barrier stop(s) out in front of the Pork Sword Chassis, all nice and close to the bore. A lightweight, minimalist, and simple solution for extending accessories up to a foot farther out front. The production version will be quick detach. (ETA late Q1, early Q2)

• Handguards — yes, yes, we’re finalizing the design on those, too. (ETA Q2)

• Stock Options — lightweight, M1913 Picatinny rail-compatible, folding stocks from Black Collar Arms are coming! These will have a typical length of pull for a rifle. Our Preferred Stock Option will have an adjustable cheek rest and butt pad. (ETA late Q1, early Q2)

• Black Collar Arms’ own custom pistol action (ETA mid-late Q2, maybe early Q3). Once ready, we will be submitting this to California’s Roster of Handguns Certified for Sale so it’s an easy purchase for our customers who aren’t lucky enough to live in the U.S. of A.

• Chassis for other firearms, from Ruger 10/22 to…well…we aren’t spilling the beans quite yet but other fits are coming very soon! Sign up for our email notifications to be…well…notified.

Please visit www.BlackCollarArms.com for more photos and lots more information, including ballistic data from our 10-inch .308 Winchester example builds.

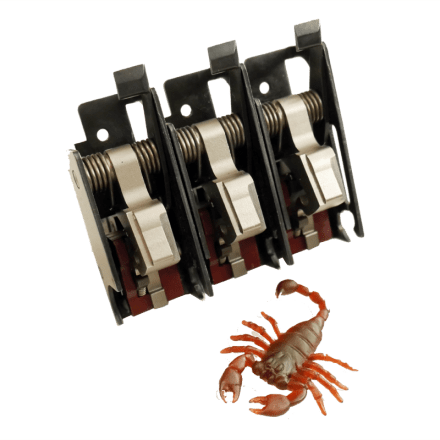

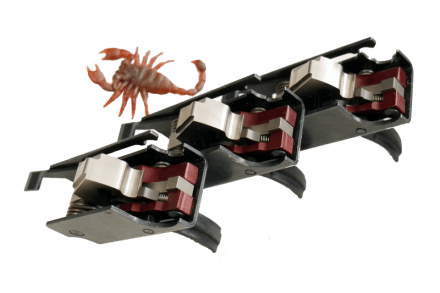

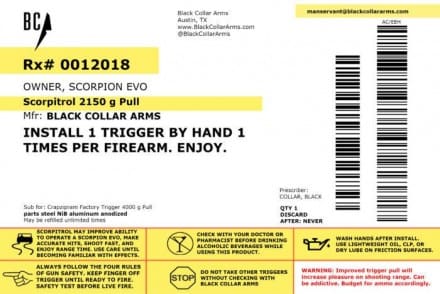

Announcing Scorpitrol®

Do you suffer from a heavy, gritty sensation in your trigger finger while shooting your CZ Scorpion EVO? If so, ask your doctor about Scorpitrol®! It’s the cure for that squeaky 9-lb factory pull and will have you enjoying a truly excellent 4.5-lb, 2-stage pull with a crisp, clean break and a short reset in only one application.

Realistically Scorpitrol® is a much better trigger than a little PDW like the Scorpion needs, but man oh man is it enjoyable to shoot!

Drop-In Scorpitrol® contains the same internal components as our Component Scorpitrol® (coming soon), but our staff of highly-trained rhesus monkeys has gone ahead and installed everything inside of a factory CZ trigger housing. It’s ready to drop straight into your Scorpion EVO!

• Maintains full-power hammer spring for reliability even with NATO-spec or cheap ammo

• Wire EDM cut hardened S7 tool steel hammer

• Wire EDM cut hardened A2 tool steel sear and disconnector

• Hammer, sear, and disconnector are polished and nickel boron treated

• aluminum inner chassis

• 2-stage trigger pull

• clean break with short, crisp reset

• 4.5-lb pull

• MSRP: $199.99

Please visit www.BlackCollarArms.com to sign up for our email notifications when new products are released — there’s a lot in the works! — and existing products are in stock.

Oh! Please go to Urban Dictionary and “thumbs up” our definition for black collar. It’s currently #8 — relegated to the second page of results. Let’s fix that!

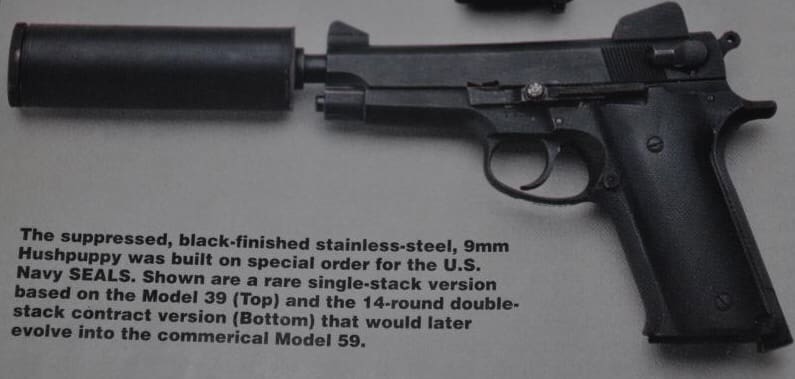

To take full advantage of the locked breech capabilities of the pistol, a new silencer design (the Model 1) featuring modular components and hybrid technology will be released at the same time. The pistol and silencer have been specifically tuned to provide maximum signature reduction with Super Vel’s Hush Puppy 147 grain FMJ subsonic ammunition.

To take full advantage of the locked breech capabilities of the pistol, a new silencer design (the Model 1) featuring modular components and hybrid technology will be released at the same time. The pistol and silencer have been specifically tuned to provide maximum signature reduction with Super Vel’s Hush Puppy 147 grain FMJ subsonic ammunition.