Now You Know What That Carrying Handle Was For

November 6th, 2017Black Aces Tactical Announces the Magazine Fed Shockwave 12 gauge

November 5th, 2017Black Aces Tactical (BAT), an American manufacturer best known for its patented custom shotguns, is excited to announce the release of the company’s new Magazine Fed Shockwave 12 gauge.

Said Lemoine, “Given the incredible success of the Mossberg Shockwave platform, it is only natural that we offer a magazine fed version of the weapon that has proven nothing short of a phenomenon. This as of late has been the question we have been receiving most. “When will Black Aces Tactical release a magazine fed version of the Shockwave?” Now that weapon is a reality.”

Starting at just $499 retail, the Black Aces Tactical Magazine Fed Shockwave offers a significant upgrade to al already incredible platform. As an option Black Aces Tactical is offering an option Tri-Rail and Magpul AFG handguard.

Specifications:

…Billet Black Aces Tactical receiver

…4140 nickel plated bolt and slide

…17-4 Stainless Steel firing pins

…The awesome Shockwave grip

…OEM Mossberg corncob forend standard

…Black Aces Tactical magazine tube spike standard

…Each weapon comes with 2 5rd stick magazines

…27.5″ total overall length

…Backward compatible to most Mossberg 500 accessories

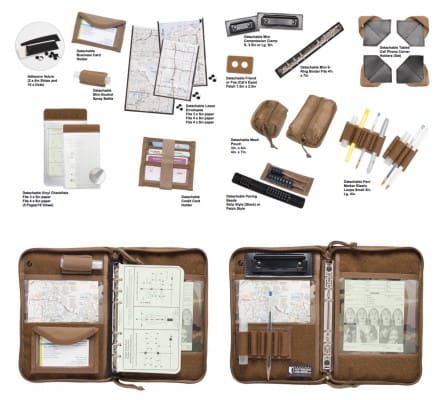

The Military Notebook Cover System

November 5th, 2017In a heated situation, you need to access that mission critical information fast. Lives can depend upon it. The new notebook cover system combines the “tried-and-trueness” of past notebook covers with the ability to individualize each cover – truly making daily use of the cover an enjoyable experience.

The Military Notebook Cover System has been designed to accommodate a variety of outdoor field data books and small binders. A 6 x 8″ military notebook fits nicely in the main compartment. Fits most commercially available sniper data books (STTU Sniper Data Book, Snipercraft Sniper Data Book, TSSI Waterproof Marksman’s Data Book, and the US Tactical Supply Sniper Data Book.

The Military Notebook Cover System is pretty functional as is – but the option to include cover Add-ons gives each user the option to really deck the cover out the way you always wanted to. Cover Add-ons (such as detachable Lexan envelopes, pacing beads, elastic marker loops, etc…) can be positioned exactly where you want them for easy access.

Available in black, coyote brown and multicam, this rugged cover is made from head to toe with military spec. materials. Completely manufactured in the USA.

IWI, An SK Group Member, Launches MASADA – A Striker-Based Line Of Pistols For Military, Law Enforcement, And Civilian Markets

November 5th, 2017Ramat HaSharon, Israel, November 2nd. Israel Weapon Industries (IWI), an SK Group member – a leader in the production of combat-proven small arms for law enforcement agencies, governments, and armies around the world – is launching the MASADA line of Striker-based pistols for military, law enforcement, and civilian markets. The first model, the full size 9X19mm MASADA, will be exhibited at Defense and Security Thailand, Milipol (Paris) France, and Expodefensa Colombia.

According to Shlomi Sabag, IWI’s CEO, “We are proud to launch this new line of pistols – the MASADA – following a development process that took several years, based on requests from our customers. The new Striker-based line places special emphasis on operational safety and simplicity of maintenance, as well as a high level of ergonomics and ease of use. The pistol will be available to our customers from Q1/18.”

The MASADA has several advanced safety mechanisms including a firing pin block safety, a clean and crisp trigger reset with a built-in trigger safety, and a fast, easy and safe takedown – with no need to pull the trigger. The pistol can be provided with or without manual safety. It has an easy racked slide with improved front and rear cocking serrations, enhanced ergonomics with the IWI grip angle, and a low barrel axis for reduced recoil. The body has a glass-reinforced polymer frame as well as a polygonal cold hammer forged barrel with a 1:10RH twist rate.

Additional features include fully ambidextrous operating controls and fixed 3-dot tritium illuminated Meprolight night sights. It offers 100% interchangeability with a compatible trigger mechanism housing, reducing maintenance and life cycle costs. The pistol has an overall length of 6.6″ (186.4mm) with a barrel length of 4.1″ (104mm), and with a trigger pull weighing 5.5-7.0 lbs. (2.5-3.175 kg), and a weight without the magazine of 22.9 ounces (650 g). The MASADA will be available in four colors: Sniper Gray, OD Green, Black, and Flat Dark Earth.

ABOUT IWI

Israel Weapon Industries (IWI), located in the center of Israel, is a world leader in small arms for over 80 years. IWI is a member of the SK Group, which comprises companies that develop and manufacture a wide array of defense products for governmental entities, armies, and law enforcement agencies around the world. IWI’s best-known products include the TAVOR, X95 (MICRO TAVOR), and GALIL ACE Assault Rifles, the GALIL Sniper Rifle, the DAN.338 Bolt Action Sniper Rifle, the NEGEV Light Machine Gun 5.56 & 7.62 mm, the legendary UZI SMG in its latest evolution – UZI PRO, and the JERICHO pistols – which have all been considered weapons of choice by military units and top law enforcement agencies around the world, and the new MASADA Stryker-based pistols. The company’s firearms are developed in close collaboration with the Israel Defense Forces (IDF): IWI and the IDF join forces in developing these weapons, whose final configurations are the product of ongoing interaction, field tests, and modifications, resulting from combat requirements and experience. All IWI weapon systems comply with the most stringent military standards (MIL-STD) and ISO 9000 standards.

ABOUT SK GROUP

SK Group is a privately held technology and innovation holding company specializing in global frontline defense, and paramilitary solutions, marine infrastructures and property development. SK Group provides small arm systems, electro-optic and laser solutions, imaging systems, naval solutions and more. Drawing on Israel’s innovation and field-proven solutions, SK’s companies offer a powerful track record of technology, experience and excellence.

For more information on IWI, please visit: www.iwi.net. Further information about SK Group is available at www.sk-g.net.

SureFire / HSP Collaboration – D3FT Light

November 5th, 2017During the grand opening of Haley Strategic Partners’ new facility in Scottsdale, Arizona, I got a preview of a new handheld flashlight collaboration with SureFire.

The Disruptive Environments Firefly Technique (D3FT) is a single cell, singie output (500 lumens), handheld light, which can be used as an expedient weapon light while using the SureFire grip.

It offers a tail cap switch. Additionally, the dual function pocket clip indexes on the body and is held down by the grip ring.

Available Jan 2018, exclusively through Haley Strategic Partners.

Introducing the B•A•T TRIDENT: A Wildly Unique New Multitool LIVE On Kickstarter

November 4th, 2017NEW HAVEN, Connecticut – November 2, 2017 – In a market flooded with multitools and pocket gizmos, standing out from the crowd is no easy feat, especially on Kickstarter. With a unique shape and carry options, Covert Products Group’s new B.A.T. TRIDENT multitool moves the conversation of EDC tools in a totally new direction.

Inspired by the familiar silhouette of side-release buckles (as found on backpacks and bags), the B.A.T. TRIDENT expands on CPG’s “bring anywhere tool” concept that debuted on Kickstarter last year. The TRIDENT – which launched this week on Kickstarter – is engineered to contain 12+ useful functions in a compact, ergonomic and highly “carry-able” package. From daily utility to survival, the TRIDENT is designed to be carried (almost) anywhere, excel at a variety of tasks, and look good doing it.

“The perfect tool isn’t so perfect if you don’t have it with you,” explains the TRIDENT’s designer Thom O’Leary. “The TRIDENT is big enough to be useful, but small enough to carry just about anywhere, either visibly or covertly. Slip it onto a backpack strap, belt, keychain, or carry it in your pocket.”

The TRIDENT functions include:

· Phillips head screwdriver

· Razor edge

· Sharp piercing point

· Captured cutter

· Flat head screwdriver/pry tip

· Wire stripper

· Serrated fire rod scraper

· Saw edge

· Laser-etched 1” ruler

· Ergonomic bottle opener operated with the tool safely held in the sheath

· Fire starter rod (included) OR swap it out for an optional EmbriteTM glow pellet from TEC Accessories

· 3M SOLAS reflective sticker

· And the TRIDENT’s molded Kydex Sheath is designed to allow multiple attachment options for everyday carry

The TRIDENT is available now through December 1st on Kickstarter, with lowest prices available for early adopters. The TRIDENT will ship during or before March 2018.

www.kickstarter.com/projects/1800078419/bat-trident-12-function-mini-multi-tool

Greyhive Training Brief, Episode 1

November 4th, 2017The Training Brief is a weekly video series released every Wednesday on the Greyhive website and YouTube channel. The episodes feature various Greyhive Experts and SMEs who cover a broad spectrum of topics ranging from mental performance to specific shooting and tactics elements. Each episode is 5 to 8 minutes and contains narrowly focused content.

The goal of the Training Brief videos is to deliver knowledge to our community that is relevant, actionable and cerebral.

Episode 1 – Spalling

Garett Schwindel of Kägwerks explains the effects of spalling and use of cover examples with Drew Estell of BAER Solutions.

To access additional training articles and content, go to Greyhive.

Armageddon Gear – The Original Gamechanger

November 4th, 2017If you participate in any form of precision rifle shooting, whether professionaly, competitively, or just for fun, you should check out Armageddon Gear. Founder Tom Fuller started making products for the best reason there is; because he needed them. The OG is one of their latest.

The design finds its roots in Reasor Precision’s simple solver that changed the game of positional shooting. Origins of Reasor’s grasping front support bag for firearm stability began with a specific shape, heavy-poly fill blend and pliable shell to yield the most effective and versatile solution developed for those uncomfortable positions that marksmen used to dread. The OG embodies the original Gamechanger in exact geometry, consistent fill and even a specially selected 1000D Cordura to replicate the feel that made this bag so great.

Specifications:

-1000D Cordura fabric available in Coyote Tan and Multicam

-Includes two handles on opposite ends for ambidextrous use

-Total weight of over 6 pounds and filled with Reasor Precision Solutions approved recycled plastic fill

-Zipper access to adjust fill to user desired ratio

Dimensions:

approximately 10″ Long

7″ Tall

6″ Wide

Proudly made in the USA!

www.armageddongear.com/The-OG–Optimized-Gamechanger