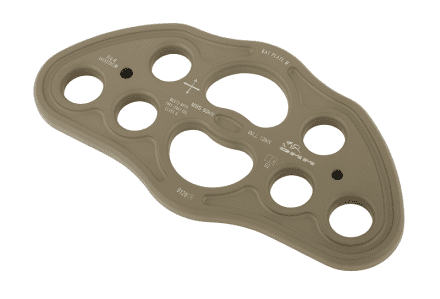

Colors and Coatings:

DMM offers a range of color and coating options on alloy and steel products to aid environmental concealment and noise suppression. Further customization services, such as identification markings and bespoke sewn elements are also available to create a custom product specific to its end use.

Anodizing:

Anodizing is the standard coating process for use on DMM aluminium products. This process not only offers corrosion and wear resistance, but also allows for color to be used for aesthetics and identification, or, in the military environment, to aid with concealment.

By fine tuning the anodizing process they are able to offer a range of subdued colours in a matte finish. The anodizing process DMM uses conforms to BS EN ISO 7599:2010 Class AA10 sealed. This process will withstand the rigors of a 48 hour neutral salt spray as described in ISO 9227.

Their standard tactical color from 2016 is Matt Grey and the bulk of their products will be available stock in this color although some will be available stock in black. Other subdued colors are available subject to a minimum order quantity.

For a number of years black has been the color of choice for tactical metal hardwear, however, it is hardly the most appropriate color to blend into any background as it produces an almost perfect silhouette and as we know, black is not often found in nature so is easily picked up by the MK1 human eyeball as being out of place.

Black seems to have stemmed from the shock and awe hostage rescue environment, however, there are now far more groups within the military employing climbing to provide a tactical advantage in wilderness, urban and maritime environments, these operators require a more subtle approach. Matt grey provides a very dull solution in all of these environments, it is far more consistent in production to get a very matt finish on grey than with other colors.

Cerakote:

Cerakote is a ceramic based coating that has excellent wear, hardness, chemical resistance, abrasion resistance andcolor consistency. Cerakote is available in a massive range of colors to suit the environment you are working in, it is also available in a reduced visual IR-signature detection version.

The main advantage of Cerakote for climbing equipment is the excellent color consistency and matt finish which allow the end user to specify colors which are impossible to achieve through anodizing.

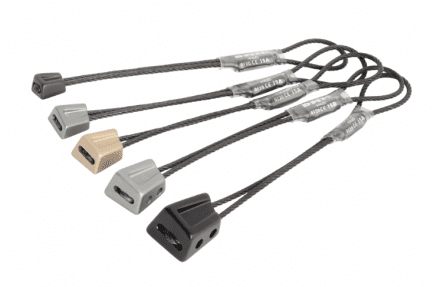

PVC Coating:

Selected products are available with a PVC coating. The PVC provides a protective coating and more importantly reduces the sound signature in environments where sound suppression is a priority.

Custom Marking

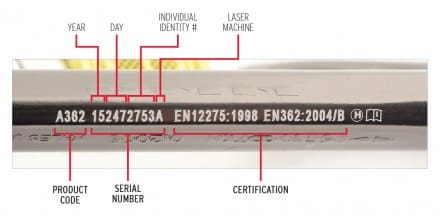

Standard Markings:

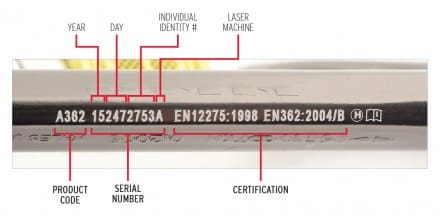

All DMM metal products carry a unique serial number and any international certifications the product complies with. The unique serial number allows every single item to be individually traced back to its original date and order of production.

Unique Customization:

DMM are also able to offer custom laser etching in addition to the normal etching required by the standards. This can take the form of identification marks and numbers to aid internal administration, through to decorative markings such as unit insignia.

Sewn Product Customization:

DMM extend their customization options to sewn products where they can sew bespoke lengths of slings in a variety of technical Dynatec, nylon and polyester webbings that are suitable for safety critical environments.

Using the same traceability they apply to their metal products, all DMM sewn products have unique reference numbers, however DMM can also customise the labelling on sewn products such as slings, quickdraws and sewn terminations on rope with unit identity codes or reference numbers.

All DMM customisation options are subject to minimum order quantities.

dmmwales.com

High Angle Solutions is a weekly feature by DMM, CTOMS, and Atlas Devices.