Nuremberg, March 9, 2018 With its GORE-TEX® SURROUND® product technology W. L. Gore & Associates (Gore) has paved the way for the production of a new class of police duty footwear. This footwear is the first of its kind to offer 360° breathability in addition to durable waterproofness. Moisture and warmth produced by the foot are not only conducted out of the shoe via the upper, but also via the sole. So, police officers’ feet stay dry and comfortable even at higher temperatures or during physically strenuous activities.

Gore’s footwear partners can now supply police duty footwear featuring the GORE-TEX® SURROUND® product technology and complying with the requirements of EN ISO 20347:2012 for occupational shoes. This footwear is characterised by a new class of climate comfort, extensive protective features, a light weight and an attractive design. In this regard it lives up to the increased expectations of police officers whose everyday, all-day work takes them indoors and outdoors, where they need to be able to rely on dependable and comfortable footwear across a wide range of activities and weather conditions. This makes this footwear the ideal solution for police officers on regular and patrol duty, as well as for policing tasks in urban areas.

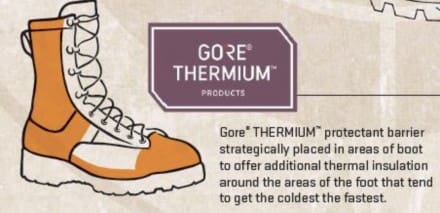

Increased overall breathability?The GORE-TEX® SURROUND® product technology a patented footwear technology that is already well established in the mountain sports and casual sectors means that police duty footwear can now also move moisture and warmth away from all-around the foot, not only via the upper, but also via the sole. As about one third of the sweat produced by the human foot is produced on the sole of the foot, this offers a considerable advantage over the police duty footwear that was typically worn in the past and was not breathable under the sole of the foot. The special structure of the GORE-TEX® SURROUND® sole creates a significantly larger area through which moisture can be moved away from the foot, increasing the overall breathability of the safety shoe. Moisture and warmth produced by the foot can now also escape from the bottom of the shoe. Via a special GORE-TEX® laminate in the sole area, they are directed into a ventilation grid from where they are conducted out of the shoe through side openings in the sole.

Tests conducted in the climate chamber have revealed that during periods of activity the relative humidity of the skin on the foot is lower and during periods of rest the speed at which moisture is moved away from the skin is significantly higher. Shoe styles engineered with GORE-TEX® SURROUND® product technology offer up to 25% more breathability than GORE-TEX® Extended Comfort footwear.

Reliable protection?The durable waterproofness of the police uniform footwear is ensured by special GORE-TEX® lining laminates that are integrated into the upper and sole of the shoe, surrounding the foot on all sides. They provide protection against exposure to water and other liquids while simultaneously preventing the penetration of commonly occurring chemicals, including diesel, AFFF fire-fighting foam (3%), sulphuric acid (37%) and caustic soda (30%), in accordance with ISO 13994/ ASTM F 903, method C1.

GORE-TEX® SURROUND® Tactical Footwear is certified in accordance with EN ISO 20347:2012 for occupational footwear and fully complies with safety legislation without restricting climate comfort in any way. The GORE-TEX® SURROUND® product technology allows for flexibility in the structure of the sole: footwear partners can choose whether they attach the sole to the upper using an injection moulded or cemented construction.

First styles on show at IWA 2018?At IWA 2018 in Nuremberg, Gore and Gore footwear partners AKU (I), CRISPI (I), FAL (ES) and LOWA (D) are showcasing the first styles within the framework of this new GORE-TEX® police uniform footwear concept.

Fabrics Division?Forty years ago the Fabrics Division of W. L. Gore & Associates revolutionised the outdoor apparel industry with its waterproof and breathable GORE-TEX® products. Today it is still a leading innovator in the field of functional garments. Products with Gore functional fabrics offer comfort and protection, allowing their wearers to set themselves more ambitious goals and experience more: both in adverse conditions and in everyday use. Whether they are hiking in pouring rain, on a military manoeuvre or attending a fire fighting incident Gore knows the needs of its wearers and the sectors in which they are active. This helps ensure that the company develops products with features that make god practical sense. www.gore-tex.com; www.gore-workwear.com