MARINE CORPS BASE QUANTICO, Virginia —

Grunts know a good ruck frame has got to last. That’s why a project team at Marine Corps Systems Command has developed a more durable pack frame; one that will better support the U.S. Marine Corps Pack that has been fielded to the operating forces since 2011.

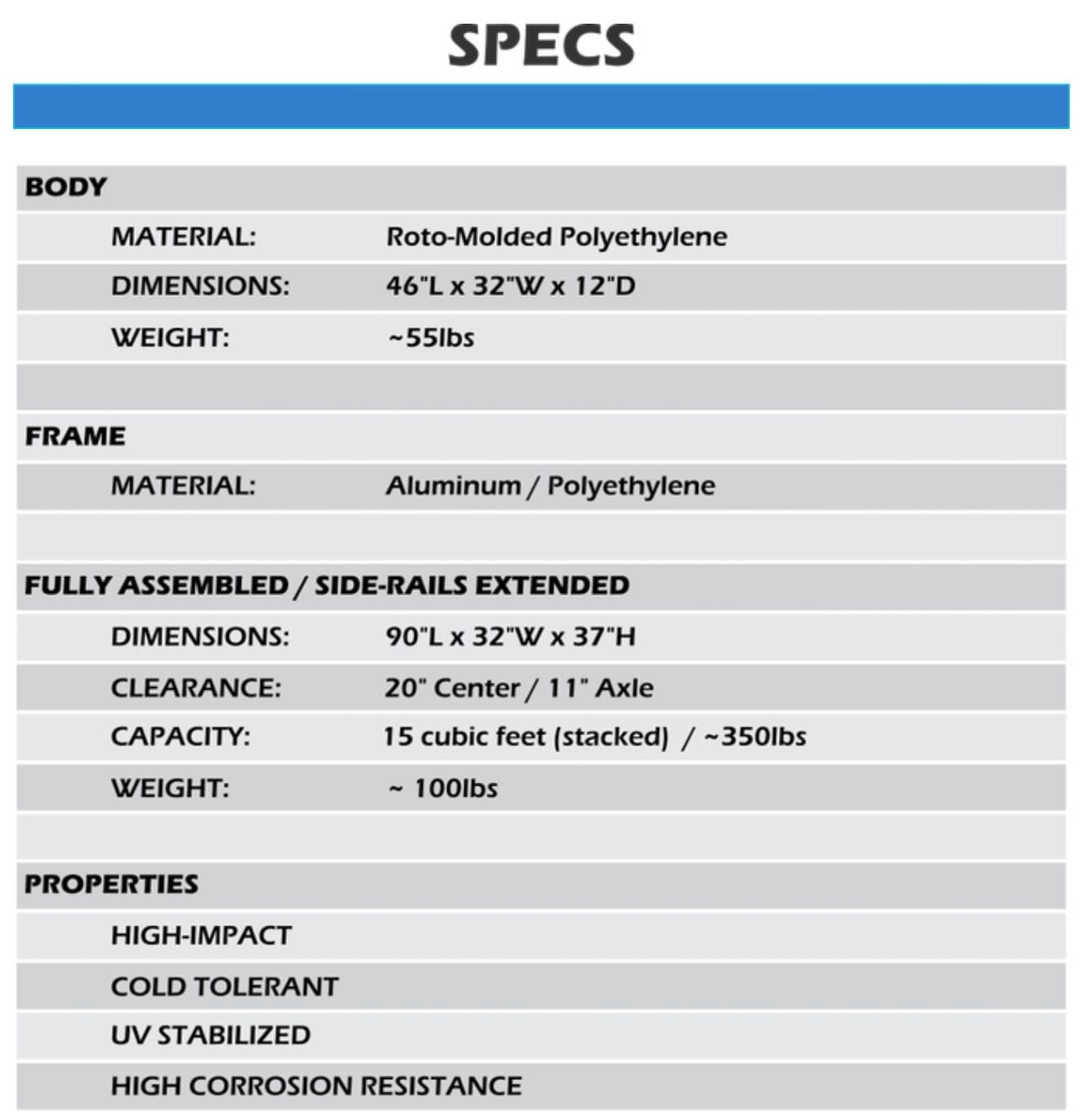

The operational force will soon begin receiving a stronger, more durable pack frame designed to endure extreme temperatures, as well as wear and tear. The reinforced U.S. Marine Corps Pack Frame provides the same form, fit and function as the current frame, with stronger materials for both horizontal and vertical load-bearing support. These improvements were made in response to feedback from Marines who reported pack frame failures in extreme cold weather environment. (U.S. Marine Corps photo by Sgt. Bryan Nygaard)

The reinforced U.S. Marine Corps Pack Frame provides the same form, fit and function as the legacy frame, but with stronger materials for both horizontal and vertical load-bearing support.

“At Marine Corps Systems Command we continually monitor progress and work to identify new ways to increase performance and durability of the pack system,” said Capt. Jolanta Krempin, a project officer for Infantry Combat Equipment. “The Marine is at the center of everything we do and their feedback is always considered with acute interest regarding acquisition programs and capabilities.”

The acquisition command first learned of pack frames issues back in 2013, when Marines from School of Infantry-West noted a small number of frames were breaking. The program office proactively began rigorous laboratory testing on a reinforced pack frame, and then tested it with Recon units to assess its durability during airborne operations. Results were positive, said a program official.

Additional legacy pack frame breakages were reported during the winter of 2015 and 2016, as Marines participated in cold weather training at the Mountain Warfare Training Center in California, and coalition exercises in Norway. According to feedback from Marines, there were issues with legacy pack frames becoming brittle and snapping.

To assess the reinforced frame’s durability in arctic environments, MCSC flew in a half a dozen program officials last winter, who handed out dozens of reinforced frame prototypes to members of a unit deployed to Norway.

“We took the feedback we got and used it to inform how we could best reinforce the pack frame, while avoiding substantial weight increase or changes in fit and form,” said Mackie Jordan, ICE engineer.

Currently, MCSC is conducting additional environmental and field testing for a more comprehensive evaluation of the reinforced frame’s performance in extreme-cold temperatures. Testing will also investigate other causes of the legacy frame’s failures to mitigate potential issues with the reinforced frame.

“The reinforced frame is being tested in both constant cold temperature environments, as well as changing temperature environments,” said Jordan. “Future testing may include hot-to-cold/cold-to-hot testing to simulate rapid temperature changes during jump operations.”

During testing, frames will be subjected to an extreme cold temperature of 0° +/- 2° Fahrenheit for a period of one week. For each test, the frame will, at a minimum, be assessed for cracking, fatigue, or stress marks and cracking noises during flexibility testing.

Fielding of the reinforced frames is planned to begin in fiscal year 2018. Over time, as legacy frames meet a to-be-determined “expiration date,” they will be replaced with the reinforced frames, eliminating issues related to aging.

By Emily Greene, MCSC Office of Public Affairs and Communication | Marine Corps Systems Command