Innovative Ammunition Technology Enhances Transport Capacity, Cuts Fuel Costs, and Reduces Maintenance Burdens for U.S. Military.

Eubank, KY (March 2025) – Shell Shock Technologies, LLC. (SST), a leading innovator in the ammunition industry, recently unveiled groundbreaking findings demonstrating the significant operational efficiencies of its lightweight ammunition. Following the December 2024 release of “Weight Reduction of Lighter Weight Ammunition & Its Impact on Troops and Aircraft/Vehicles,” SST’s latest analysis highlights how a 30 percent reduction in ammunition weight translates to streamlined logistics, lower transportation costs, and substantial military savings.

Increased Transport Capacity and Cost Savings

SST’s lightweight ammunition enables more efficient transportation logistics. Traditional .50 caliber ammunition requires approximately ten pallets per transport vehicle, costing nearly $4,000 per trip. SST’s lighter ammunition increases payload capacity to fourteen pallets per vehicle, effectively eliminating the need for every fourth vehicle. This reduction in convoy size leads to fewer shipments, lower fuel consumption, and decreased risks associated with transport missions.

Moreover, for surface transport, every third 20-foot International Organization for Standardization (ISO) shipping container—costing around $22,000 per container—would be eliminated, further reducing military logistics expenses.

Aircraft Fuel Savings and Extended Range

The weight reduction extends beyond ground logistics. A 30 percent decrease in ammunition weight translates to a 9–15 percent reduction in fuel costs per aircraft mission. Given the U.S. military conducts approximately 200,000 aircraft missions per year, this equates to over $1.16 billion in annual savings.

Additionally, aircraft carrying lighter ammunition can remain on station longer, reduce refueling needs, and experience extended range capabilities. Lower weight also reduces wear and tear on airframes and engines, leading to decreased maintenance costs over time. Since fuel accounts for 40–50 percent of aircraft operational costs, reducing payload weight directly enhances efficiency and financial savings.

Maintenance and Equipment Longevity

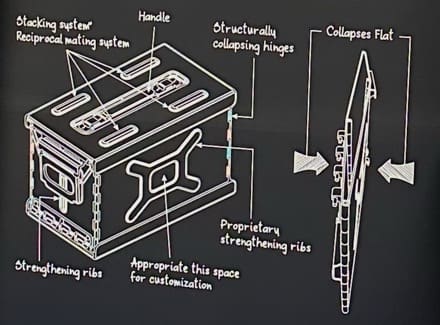

Reducing ammunition weight has profound implications for maintenance and equipment longevity. The lower payload weight decreases stress on military vehicles, aircraft, and material handling equipment. SST’s collapsible lightweight ammo can (CLAC) further enhances logistics by reducing packaging weight and allowing for a fully loaded can (100-round belt) to decrease from 35 lbs. to approximately 26 lbs. This leads to longer-lived assets, lower operational strain, and fewer maintenance requirements, ultimately increasing overall military readiness.

Environmental and Reusability Benefits

In addition to cost savings and operational efficiencies, SST’s innovations contribute to environmental sustainability. The prototype CLAC is collapsible, reusable, and fully recyclable, reducing waste and procurement costs. These enhancements provide logistical advantages while aligning with the military’s ongoing sustainability efforts.

“Shell Shock Technologies’ innovative ammunition solutions not only provide a tactical advantage but also revolutionize military logistics,” said Peter Foss, Managing Partner and CEO of Shell Shock Technologies. “By reducing ammunition weight, we are enabling our armed forces to optimize transport efficiency, cut fuel consumption, and extend the lifespan of critical military assets. This is a game-changer for both cost savings and operational readiness.”

Shell Shock Technologies remains at the forefront of ammunition innovation, providing solutions that improve battlefield effectiveness while significantly lowering the financial and logistical burden on the military.

Keep up with Shell Tech’s advanced ammunition on the website.