This week, we’re highlighting overrun stock of some of our best selling carrier systems, Strandhögg™ V1 SAPI Cut, Sloucher, and the Ragnar Vest. These are limited stock items so pricing and quantity are available while supplies last.

The Strandhögg™ V1 SAPI Cut Plate Carrier takes its name from an old Norse Viking term for, a lightning raid, Strandhögg was one of the first formalized battle tactics to use covert infiltrators in advance of an actual raiding operation. This system can be worn with or without a soft armor panel depending on ballistic requirements, threat level and plates utilized. Using streamlined fit throughout, along with state of the art materials and production technology, you’ll find this carrier to be extremely comfortable without compromising durability and performance.

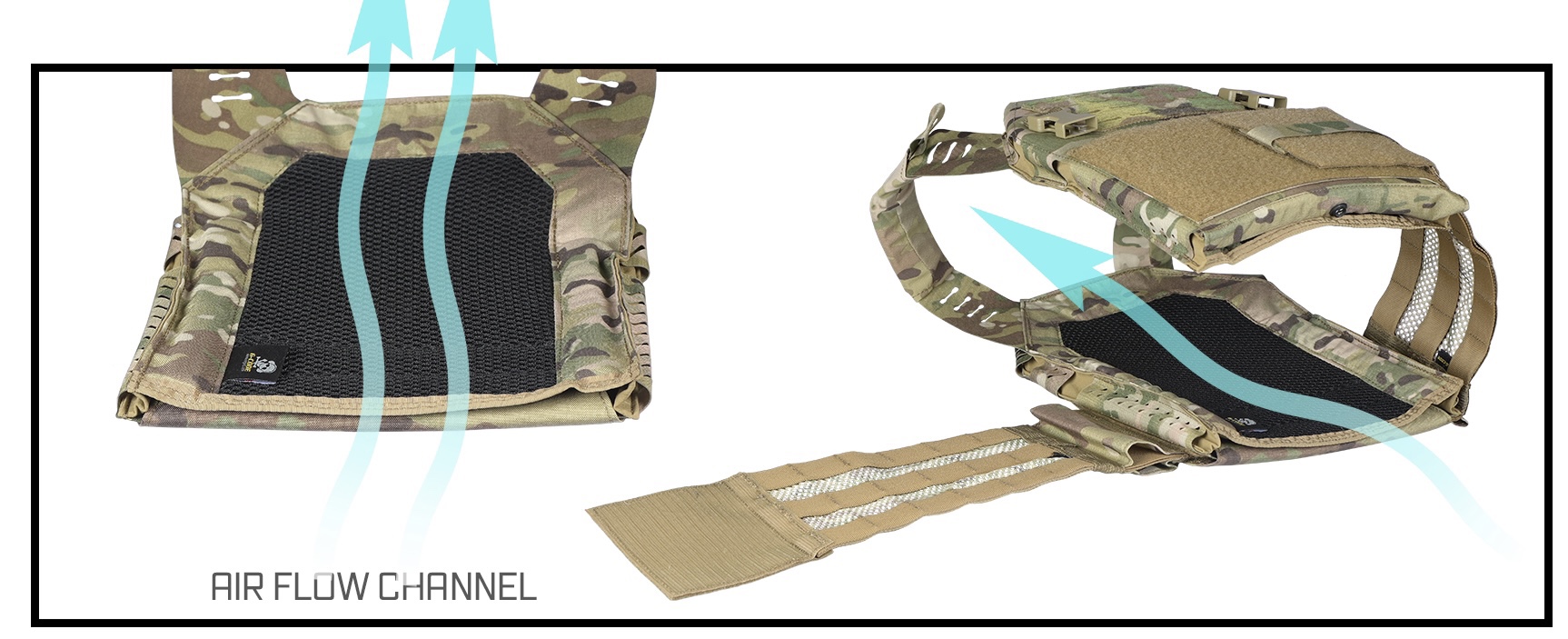

The Sloucher combines many of the most desirable features of both the Siege-R and the Sleeper. Stretch panels on the cummerbund and Tubes® closures keep the fit tight and allow for quick donning and doffing. The 6/12™ Pocket Attachment System provides a low profile. This carrier accepts front, back and side plates, SPEAR/BALCS cut soft armor (not included) and MASS accessories. The Sloucher provides the capability to support a full spectrum of operations.

Named for the intrepid explorer and cunning warrior Ragnar Lodbrok, the Ragnar Vest and its accessories are suited for a wide variety of roles and circumstances. The Ragnar Vest is covered in loop fabric and can be altered with different cummerbunds. Four special built-in pockets with retention tabs allow for storage of accessories based on situational requirements. This is a multi-mission vest with the flexibility to cover a variety of profiles.

Visit FirstSpear to find America’s premier tactical gear and equipment.