Occasionally, we get the opportunity here at SSD to share some great writing by fellow members of the profession of arms.? “The Missing Aspect of Soldier Lethality: Improved Armor Carriers in a Constrained Fiscal Environment” was written by US Army CPT Daniel Vazquez in an interest in providing his troops with more effective armor carriers.

Anyone who has been issued body armor in the conventional Army knows that it is bulky, heavy, and less than ideal. This has often led to individuals purchasing their own plate carriers. In today’s article, one Soldier went a step further and conducted testing and evaluation of several commercial options in comparison to the current Improved Outer Tactical Vest and Soldier Plate Carrier System to show the commanders above him the data showing improved performance. With one of the current modernization efforts in the Army being Soldier Lethality (covered here on SSD as well) the concept of providing Infantrymen, Cav Scouts, Forward Observers, etc with better plate carriers compared to support personnel doesn’t seem like too far a stretch these days.

We are lucky to share his work with others who may be in a similar situation. Below is an abridged of the full work. A link to entire study is available at the end of the post.The Missing Aspect of Soldier Lethality: Improved Armor Carriers in a Constrained Fiscal Environment

“All the campaigns which we have studied lead us to the same conclusion, that the load carried by the infantry soldier must be reduced.”

– Report of the Committee on the Lessons of the Great War, October 1932.

In February 2018, then Secretary of Defense Jim Mattis, announced the creation of a Close Combat Lethality Task Force (CCLTF) whose mission is to improve “the preparedness, lethality, survivability, and resiliency of our Nation’s ground close-combat formations”. In the two years since, great strides have been made in cutting through the bureaucracy and red tape regarding acquiring “kit” for this force. The roughly 100,000 personnel identified are the potential recipients for a new rifle, optic, night vision and augmented reality heads up displays, a synthetic training environment, and more. Something that is missing, however, is any mention of a push to improve the current defensive equipment fielded by this force. The majority of this force relies on the legacy Improved Outer Tactical Vest (IOTV) and Soldier Plate Carrier System (SPCS) body armor systems, made to meet the Army’s lowest common denominator human factors, to hold their ballistic plates and soft armor.

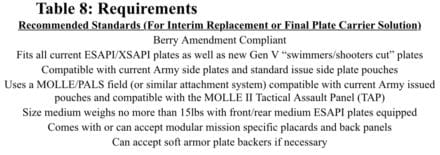

With the XVIII Airborne Corps as the USFORSCOM proponent, I propose that the CCLTF should work with PEO Soldier’s Soldier Requirements Division to authorize rapid Other Transactional Authority (OTA) procurement of commercially available plate carriers. These plate carriers should offer decreased weight and improved mobility in comparison to current (IOTV/SPCS) and future (Modular Scalable Vest (MSV)) systems and would be for the Army’s conventional component of the force. This Army Conventional Close Combat Force (AC3F) as defined in this paper consists of the same Military Occupational Specialties (MOS) that are to be the recipients of the Next Generation Squad Weapon (NGSW), ENVG-B Night Vision, and Integrated Visual Augmentation System (IVAS) programs. Lessons learned over the past 19 years of warfare should drive purchasing and equipping decisions for the AC3F, independent of the rest of the Army. This can be immediately applied with options that are currently available, for less than what the Army already pays for the MSV, IOTV, and SPCS.

Testing, Evaluation, and Methodology

In order to compare plate carrier systems performance to the IOTV, multiple tests were ran to evaluate plate carrier performance versus current Army issue (table 1 to table 4). Omitted from this testing is the Crye AVS as the AVS is already a standard within USASOC and 1st SFAB. Those interested should search USASOC’s and 1st SFAB’s testing/selection of it. All plate carriers tested in this T&E are aftermarket ones personally purchased or donated to provide examples of alternate choices. The goal of this paper is to inform the reader of other potential options on the market, not to sell a particular plate carrier to the Army. All tests were oriented around soldier performance related to combat activities.

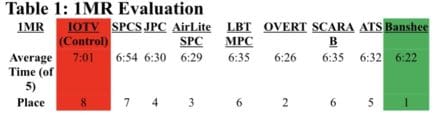

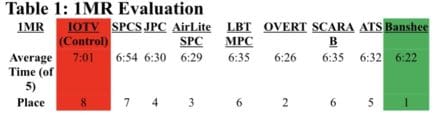

Table 1: 1 Mile Run (1MR) for time. Uniform for testing was the standard army IPFU. All individuals conducted a one mile warm up jog at the start of each testing day. Service members then rested for five minutes before conducting the one mile run for time. All individuals rested for eight minutes between IOTV/plate carrier iterations. No more than three iterations were conducted per day in order to avoid significant degradation of the service member’s cardiovascular ability to the point where it would significantly affect test results.

All participants averaged 9 – 41 seconds improvement in their plate carrier times (pending type of carrier) versus their IOTV control times. Of note is that all plate carrier times were faster than the IOTV even though the majority of plate carrier runs occurred as second or third iterations versus all IOTV times were done first to eliminate fatigue from factoring into the control time. See Table 1 below for all times. Times highlighted in green were the fastest recorded times and those in red were the slowest recorded.

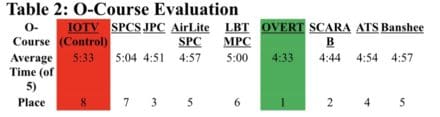

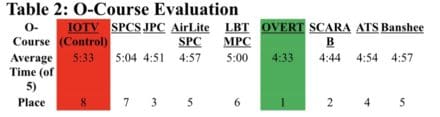

Table 2: O-Course Evaluation. Uniform for this testing was OCP pants, OCP top, boots, and tan t-shirt. Control time was run with IOTV. Service members conducted a warm up iteration wearing a slick uniform before resting five minutes before conducting the first iteration. Service members then rested 5 minutes and then conducted the event again wearing a plate carrier. Four iterations (not including the warm up iteration) were conducted per day.

All participants averaged 29 – 60 seconds improvement in their plate carrier times (pending type of carrier) versus their IOTV control times. All plate carrier times were faster than the IOTV even though the majority of plate carrier runs occurred as a second or third iteration. See Table 2 below for all times. Times highlighted in green were the fastest recorded times for the carrier and those in red were the slowest recorded. O-Course obstacles (in order) were as follows: 260m run, 2x 6ft wall, balance beam, monkey bars, low wall vaults, and a forty five degree wall. The event occurred as follows: a complete lap of the O-Course, followed by all listed obstacles for time. The intent of the event is to replicate movements (run/jump/climb/balance) required during combat operations in complex terrain.

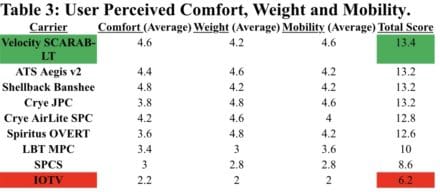

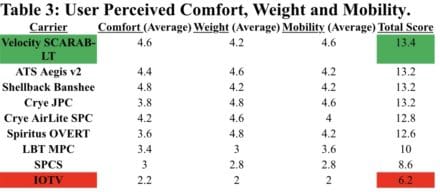

Table 3: Combat PT Stress Event. Uniform for this testing was OCP pants, boots, and Tan-T shirt. Control group was established using IOTVs. For each carrier all individuals conducted a 50m 190lbs SKEDCO drag, a 100m farmers carry with 2x 53lbs kettlebells and a burpee every 25m, 15x 30inch box jumps, 5x 225lbs deadlift, 5x 135lbs hang clean, 5x 95lbs thruster, 3x standing long jump, and 5x tire flips using a Medium Tactical Vehicle (MTV) tire. The purpose of the event was to replicate movements common to combat environments. Each participant conducted a round and then swapped carriers. At the end of each round, each service member rated the carrier just worn by its perceived comfort, weight, and mobility. All participants evaluated each carrier on a scale from 1 (lowest) to 5 (highest) and swapped carriers prior to the next iteration. Each carrier was rated separately, all individual ratings were then averaged together. The individual factor scores (Comfort/Weight/Mobility) were then added together for a total score.

Table 4: The final event was MOUT/SUB-T training at Fort Campbell’s Cassidy MOUT Site. Following the conclusion of testing all participants were told to rate all plate carriers from most desired to least desired based on the question, “if you could only deploy with one for nine months knowing you would be operating in mountainous and urban environments in mounted and dismounted operations.” Each carrier votes were tallied and the places averaged. The scores of the user preference ranking were then combined with the previous ratings from O-Course, Combat PT, and 1MR times for an overall ranking.

Findings & Recommendations

The results of all testing bring to light four points. First, the government provided carriers (IOTV and SPCS) came in last after averages were taken for all events. Second, while the IOTV and SPCS consistently came in the bottom, the commercial carriers all varied in test results depending on the event, though all greatly surpassed the IOTV and SPCS. Third, at least amongst the sample population, the service members who participated in testing all valued smaller profile and lighter carriers for their use. Finally, amongst the top four places (with six carriers altogether due to two ties) the first place carriers and the fourth place carriers differed by only three points while the difference between the fourth place and fifth place had a difference of nine and between four and last a difference of fourteen showing that at least amongst the top four places that there is little variation in overall performance when comparing quality manufacturers and all perform much better than the government options.

The current next generation vest/plate carrier that the Army is developing is the Modular Scalable Vest (MSV). Part of the Soldier Protection System, the MSV portion is meant to replace everything from current concealable body armor to plate carriers to a full IOTV-style set up to include deltoid and groin protection. The issue that befalls the MSV is, like the IOTV, in an attempt to do everything, it will do nothing well. Part of this is from the intense focus on modularity. When it comes to the mass issue of a single system to fill multiple roles then having a modular system is understandable. A mass issue to a service with over one million personnel across all three components (Active/Guard/Reserve) fits the older fits the older industrial age Army but not that of a modern information age one. When one focuses on what level of modularity is actually needed for a force like the AC3F is it often actually less than what is provided by the MSV.

A plate carrier for the AC3F should meet the modularity requirement through compatibility with exchangeable back panels, different placards, as well as cummerbunds and/or a structural harness. The Crye AVS, Spiritus Systems LV-119 OVERT, and Velocity Systems SCARAB-LT are all excellent examples of the right sort of modularity that is needed for a member of the AC3F. The MSV’s level of modularity will ensure it meets basic requirements for the larger Army but over compensates in the categories that will actually benefit the AC3F.

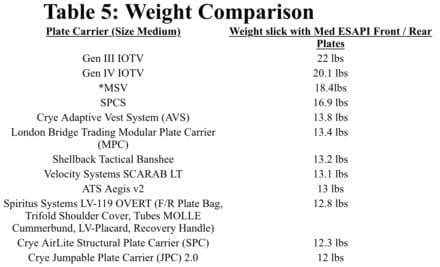

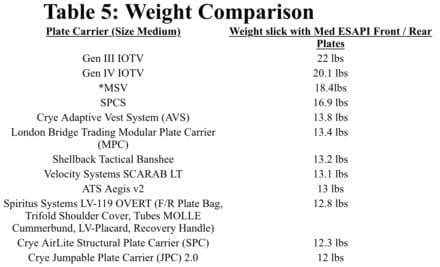

Note: With the exception of the MSV, all weights were taken using an ETEKCITY model EL11 Scale

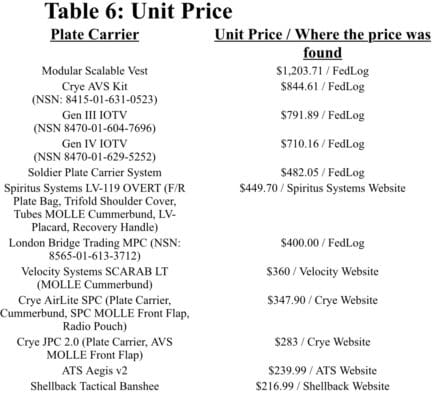

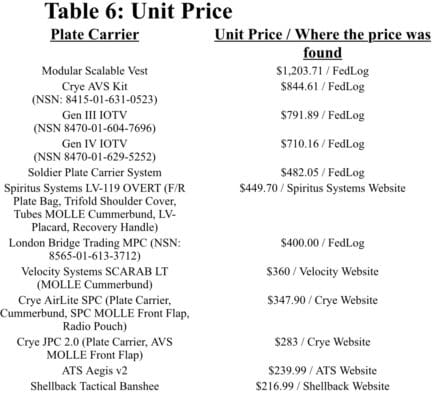

The use of commercial options currently on the market will also save the Army money. If the Army were to outfit the members of the AC3F with the Crye AVS Kit instead of the MSV, it would save $359.10 per individual. If the Army chose to outfit the AC3F with the LBT MPC instead of the MSV it would save $803.71 per person. In fact, the Army would be able to field three MPCs for the cost of one MSV. View further comparisons listed in table 6 (below). From a financial standpoint, the Army budget is in constant flux. The Army already conducts multiple “night courts” to determine which programs to cut in order to allocate funds towards modernization efforts. By purchasing a commercially available carrier for AC3F personnel the Army can use the saved money towards other programs. For some carriers, prices may vary depending on whether or not they are purchased as a kit or in a specific configuration.

Note: non-FedLog prices do not take into account price reduction due to bulk purchase and/or contract by the U.S. Army.Recommendations

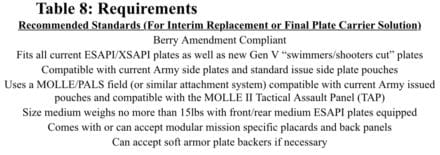

In order to facilitate a transition to an improved plate carrier, the recommended course of action is that the Army either mirrors 1st SFAB’s 2017 procurement of the Crye AVS (via PEO Soldier and USSOCOM PM-SSES) as the example in the purchase and issue of improved systems or uses Other Transactional Authority (OTA) methods of procurement. The XVIII Airborne Corps, with the support of the Maneuver Center of Excellence, should be the proponent and initial force to test and evaluate through several soldier touch points and be the first recipient of the selected system. The XVIII Airborne Corps fits the requirement for evaluation due to the existence of three different formations (light, airborne, and armored) within it.

As an interim solution, the Army should identify a list of suitable options until a permanent solution for the AC3F is chosen and authorize, at either the Corps or Division level, funds for the purchase from single vendor for the interim carrier to meet the needs until the CCLTF and/or Soldier Lethality Cross Functional Team can settle on a single carrier to meet the need of the warfighter. This sole carrier purchase will prevent the fielding of multiple different plate carriers and thus reduce the training complexity of needing to train multiple different carrier types for removal under stress.

The selection of a plate carrier separate to what KDH already offers the Army does not need to impact the current contracts already held by KDH either. Rather, the fielding of separate equipment to the AC3F can help facilitate the fielding of the MSV to non-AC3F personnel as the overall number required to receive the vest will be reduced.

Conclusions

To be clear, this paper is not arguing for “cool guy gear.” Gear alone does not dictate performance. While kit alone does not guarantee performance, it does effect a soldier’s overall performance when considering the Soldier as a holistic system and not one of an individual simply loaded down with equipment. As we improve the individual soldier, the squad will improve as well.

The MSV may suit the needs of MOS’s separate of the AC3F but it will not facilitate the close combat force in the overall effort of creating a more lethal Squad. If the MSV were to exceed the requirements of the close combat force, then units like the 75th Ranger Regiment would be fielding it en masse to replace their current systems. This is not the case. While members of the SFAB that was fielded MSVs may have stated that PEO Soldier “got it right this time” the SFAB is not a combat unit in regards to the forces identified as part of the Close Combat Force. The article in which the SFAB Soldier is quoted also does not specify the service member’s MOS nor his or her knowledge in regards to other offerings on the market.

The bottom line is this: if America’s close combat force is different enough to warrant improved rifles, machine guns, and night vision, then it certainly warrants improved plate carrier solutions as well. The solution already exists on the commercial market with multiple options vastly superior to the current standard issue. All this exists at a price point less than the “solutions” that have been issued to the primary fighting force for far too long. So long as the commercial carrier can meet a set of established requirements (the requirements used by USASOC are a good starting point) and is using Army issued ballistic packages there is little downside for the AC3F end user. Given the prices of some sample options (not taking into account reduced cost from bulk orders), the Army would also save money by purchasing these systems versus the IOTV/SPCS/MSV.

In the end, the CCLTF exists to improve the lethality of America’s close combat forces and to enable them to remain the preeminent ground fighting force into the foreseeable future. Part of this objective can be achieved by equipping said forces with improved plate carriers to reduce weight and increase mobility. This is a “win-win,” if there ever was one. A decrease in weight will reduce fatigue on the soldier during long movements or in combat situations. Reduced fatigue will translate into better decision making, better employment of their weapons systems, and easier recovery if a service member is injured and unable to be moved under his or her own power. Lastly, a decrease in cost means more carriers can be purchased for the same price, or money can be saved for the same numbers. It is for these reasons that the Army should equip its AC3F warfighters with superior equipment today in order to set conditions for success in the future.

Special Thanks to Velocity Systems, Spiritus Systems, and ATS Tactical Gear for providing demonstration plate carriers and components for Testing & Evaluation. All other plate carriers used for T&E were either issued or a personal purchase by those participating in the testing.References

Note: All Pictures of worn carriers includes Army issued side plates and, with the exception of two carriers with side plate pouches organic to the cummerbund, IOTV side plate pouches to highlight compatibility with current issue equipment.

Ref 1: Modular Scalable Vest (MSV) on display

Ref 2: Crye Adaptive Vest System (AVS)

Ref 3: Generation III Improved Outer Tactical Vest (IOTV)

Ref 4: Generation IV Improved Outer Tactical Vest (IOTV)

Ref 5: Soldier Plate Carrier System (SPCS)

Ref 6: London Bridge Tactical Modular Plate Carrier (MPC)

Ref 7: Shellback Tactical Banshee

Ref 8: Crye AirLite Structural Plate Carrier (SPC)

Ref 9: ATS Aegis v2

Ref 10: Crye Jumpable Plate Carrier (JPC)

Ref 11: Velocity Systems SCARAB-LT

Ref 12: Spiritus Systems LV-119 OVERT

CPT Daniel Vazquez is a 2013 graduate of Norwich University’s Corps of Cadets and has a B.A. in history. Commissioned as an infantryman in 2013, he has served in both Stryker and Infantry Brigade Combat Team formations as a Rifle Platoon Leader, Company Executive Officer, and Scout Platoon Leader. He is currently serving as the Battalion Operations Officer in an IBCT Infantry Battalion. He is the author of “The War Yet To Come: A Story of the Future Battlefield” available on Amazon Kindle. The views and opinions described in the paper are his, and do not reflect the official position of the U.S. Army.

You can download your copy of the complete study here.