Company will unveil its new Lighthawk™ Tactical brand, with comprehensive, state-of-the-art

ballistic systems, carriers and accessory offerings for the modern-day tactical officer

CENTRAL LAKE, MI, January 18, 2018 — Central Lake Armor Express, Inc. (“Armor Express”), a leading manufacturer and distributor of high-performance body armor solutions, is excited to unveil its latest advancements in ballistic packages, carrier designs, hard armor, and duty gear for the Domestic and Federal law enforcement, defense and security markets at the 2018 Shooting, Hunting, Outdoor Trade Show (SHOT Show). Armor Express will also formally launch its new brand, Lighthawk™ Tactical, demonstrating the hottest innovations in head to toe protective wear for the 21st century tactical officer at Booth #31103. The conference, which is organized by the National Shooting Sports Foundation, will run from January 23-26 at the Sands Expo Center in Las Vegas, Nevada.

“SHOT Show provides an incredible opportunity for us to fully engage with our customers and partners on what’s most important: saving lives,” said Matt Davis, Founder and President of Armor Express. “We look forward to highlighting the most cutting-edge tactical and concealable solutions the industry has seen, all reflective of our commitment to putting the safety of the men and women who protect our freedoms above all else. We continue to expand our footprint, most notably growing our tactical LE business with the launch of Lighthawk Tactical, which will bring a host of new innovations and greater industry collaboration. As we push advancements in ballistics and carrier designs, there is no better time than now to be front and center with those who rely on our solutions. We look ahead to a productive conference.”

Lighthawk Tactical Takes Technology-Driven Body Armor Designs to the Next Level

Expected to be one of the biggest highlights of the show, Armor Express will debut its new Lighthawk Tactical solutions developed with real-world user input and dedicated to the progressive tactical officer. Under the Lighthawk Tactical brand, Domestic and Federal law enforcement officers will benefit tremendously from the latest mission-critical ballistic systems, carriers, hard armor and accessory tools, including the:

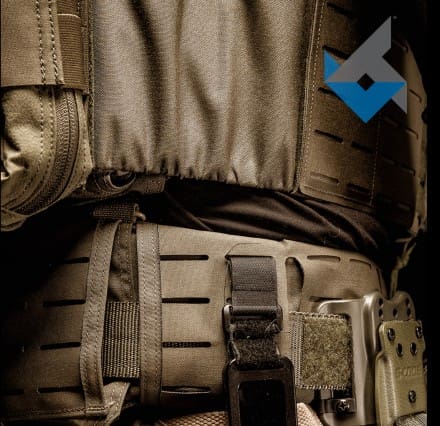

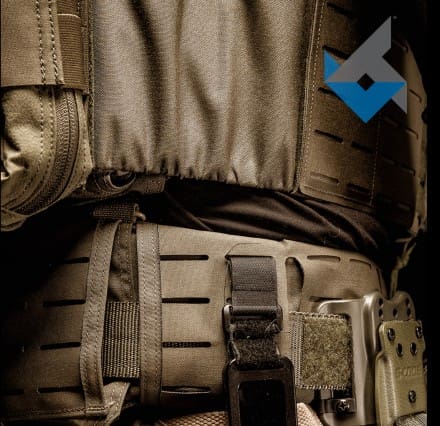

– Special Assignment Unit (SAU) Plate Carrier: This streamlined, lightweight and modular tactical plate carrier comes in Laser Cut and MOLLE configurations and features the Quad Ventilation Liner (QVL) and optional/swappable Cummerbund Wraps (Armor Wrap, M4 Wrap, Utility Wrap).

– Laser Cut Plate Carrier (LCPC): Fits most hard armor plates (certified ICW or Lo Vis special threat) and soft ballistic plate backers. The LCPC meets most needs for patrol, task force, or close protection detail. This lightweight carrier is made with today’s newest and strongest materials.

– Hard Armor Shoulder Plate (HASP) Carrier: This advanced, lightweight, ballistic (Level IIIA, III, or III+) shoulder protection plate and carrier is exclusive to Lighthawk. The HASP carrier was engineered with the latest laser cut material resulting in a durable, low-profile and reduced-weight product.

– Agile Canine Vest (ACV): With ground-breaking features like the hidden dynamic cummerbund, shoulder fit adjustments and covered zipper closure, the ACV is a streamlined package allowing the K-9 to move freely with minimal snag points, while offering the best options in ballistic/stab protection.

– Quick Release Dynamic Cummerbund Upgrades: Using cutting-edge technology, Lighthawk Tactical is proud to deliver three cummerbund options for the most discerning operator – the Cobra® Dynamic Cummerbund, Ares® Dynamic Cummerbund, and FirstSpear® Tubes® Dynamic Cummerbund.

– Special Response Team (SRT) Belt: The SRT Belt offers an effective and comfortable platform for today’s officer needs. Available in MOLLE and laser cut styles, it comes standard with a padded insert or can be upgraded with a custom ballistic insert. Sizes run from XS-4X.

– NOD’s Garage: This padded case for a helmet-mounted night vision device or related accessories, utilizes the interior space and protection of the operator’s helmet, making the most out of limited loadout space. It includes ID badge and name tape attachment points, along with a removable divider.

View the innovative Lighthawk Tactical solutions at bit.ly/shotshowproducts.

In addition to these latest offerings, the Company will exhibit under the Lighthawk umbrella, its ‘tried-and-true’ XT 2.0 tactical vest; Tactical Operations Response Carrier (TORC); Busch ballistic helmets certified to VPAM; M1, R1 (rifle-rated) and S1 ballistic shields; and Peraflex System Pouches.

“Lighthawk Tactical is committed to creating and delivering solutions which support the needs of the modern-day tactical professional,” stated Rick Rardon, Director of Carrier Research and Development. “We’re excited to introduce at SHOT Show some of the industry’s firsts and strongest innovations for tactical LE. This is an ideal forum to actively engage with our end-users. Their feedback is instrumental to our product evolution process and we pride ourselves on the Lighthawk brand being mission-ready and second-to-none because we put our customers’ needs at the forefront.”

Within the broader Armor Express portfolio, attendees can look forward to seeing the Company’s latest capability enhancements, including its:

– Seraph Gen3 Soft Armor: An incredible armor system that’s thin, light and pliable as a result of the ideal blend of Teijin® Twaron® and Dyneema® Force Multiplier Technology.

– American Revolution Concealable Carrier: A superior design, while offering maximum comfort, breathe-ability and durability. Low profile shoulder padding adds comfort and weight disbursement.

– Hardcore H3 Overt Patrol Carrier: Features a lightweight, low profile architecture with fully adjustable shoulders and waist. It uses BRAVO cut panels for enhanced coverage and a more accurate fit.

– Hard Core FE: This is the first Fire and EMS-specific carrier to safely address a one-size-fits-most application with consideration of comfort, movement and ballistic protection.

– OCS UVIR: This lightweight, external body armor is designed to go over a uniform shirt. It protects the Fire/EMS personnel from handgun threats as part of a Unified Violent Incident Response (UVIR) team.

– Tactical Outer Garment (TOG): This scalable, tactical armor system offers advanced features, including National Molding® Back Release System, developed specifically for Dept. of Homeland Security agents.

Other industry-proven products such as the Halo, Razor, Vortex, FMS, Gemini, and Taurus soft armor packages; the Revolution concealable carrier; and Traverse overt patrol carrier with latest Dress configuration will also be on display at the Armor Express booth.

In conjunction with the Lighthawk Tactical premiere, Armor Express is honored to support the Concerns of Police Survivors (C.O.P.S.) foundation in a fundraising drive throughout the week at the Company’s Booth #31103. As a ‘thank you’ to donors, the AE team will be gifting top quality swag items highlighting the Lighthawk Tactical brand. Attendees are encouraged to stop by the booth – while supplies last – and support an amazing cause and organization. Each year, between 140 and 160 officers are killed in the line of duty and their families and co-workers are left to cope with the tragic loss. C.O.P.S. provides resources to help survivors rebuild their shattered lives. For more information, please visit www.nationalcops.org.

Mr. Davis continued, “2018 ushers in a new beginning as Armor Express merged with KDH Defense Systems, combining forces to create one of the largest body armor and protective solution providers in the world. Together the companies will proudly serve our Domestic and Federal law enforcement agencies and U.S. Armed Forces, leveraging best practices and creating a winning formula for our protectors and partners. We are excited by what the future holds and look forward to building long-lasting alliances for years to come.”

www.armorexpress.com