INKAS® Armored Vehicle Manufacturing proudly announces the world’s first Armored Lexus GX 550! The vehicle seamlessly blends Lexus’s signature bold design and advanced driving technology with discreet armored protection. The Armored Lexus GX 550 is a harmonious merger as the vehicle itself is a powerhouse, setting the standards for luxury, safety, and performance. It is a class-leading choice for discerning clients seeking both style and security.

Masterfully crafted by INKAS®, the armored Lexus GX 550 reinforces the original vehicle’s ruggedness and athletic capabilities with military-grade enhancements, all while preserving the GX’s sleek but tough aesthetic. Beneath its refined exterior, certified ballistic steel plating and ballistic glass shield occupants from ammunition attacks, collisions, and even grenade blasts. The vehicle’s robust 20-inch wheels, paired with INKAS® runflat systems, enable the armored Lexus GX 550 to stay operable through single or multiple punctured tires for long distances.

“As the first company to armor the Lexus GX 550, we’ve created a vehicle that offers class-leading protection while maintaining the comfort and sophistication that Lexus is known for. Yet another milestone in the armored vehicle industry under our belt.” Said Margarita Simkin, INKAS® Chairwoman.

“As it has been for three decades, our mission here at INKAS® is to maximize occupant safety without compromising luxury, reliability, or performance,” she goes on to say.

Embodying the comfort and bold design Lexus guarantees, the GX 550 is solidifying its presence with a square body profile, exceptional towing strength, and modern technology traits. This gives the armored vehicle a commanding presence that maneuvers through both city streets and unpredictable terrain just the same.

The vehicle’s key features include:

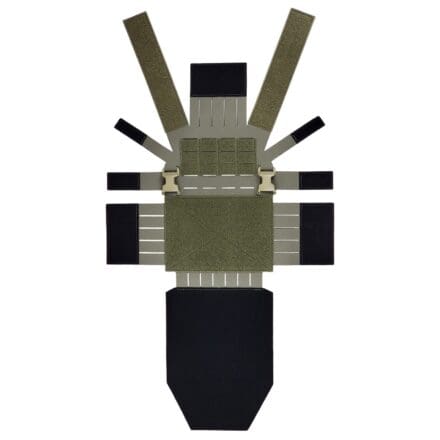

Certified Ballistic Protection: Lab-tested ballistic steel and glass are certified to withstand attacks from all angles. The armor is integrated between the vehicle’s original exterior and the chassis, resulting in a discreet armoring solution.

Runflat System: Enables safe operation even with punctured tires, ensuring mobility in critical situations. The devices are military-grade and installed directly onto the vehicle’s rim.

Luxurious Interior: Seamlessly integrated armored components designed to blend with Lexus’s premium finishes. Intuitive driving technologies are integrated to enhance driver and passenger comfort. This is evident through the 14-inch display screen that offers an extensive road map view and Apple car play functions.

Rugged Versatility: The GX 550’s intuitive driving technologies and off-road capability make it a reliable choice for any terrain. With an aggressive off-road focus, this vehicle hosts a dependable and smooth journey guarantee.

The Armored Lexus GX 550 offers unprecedented peace of mind without sacrificing style or performance. The world’s first Armored Lexus GX 550 is now available for orders worldwide.

inkasarmored.com/armored-lexus-gx-550