HOHENFELS, Germany — Lighter. Faster. More agile.

The U.S. Army implemented its Transforming in Contact initiative during exercise Combined Resolve 25-1 at the Joint Multinational Readiness Center in Germany’s Hohenfels Training Area from Jan. 17 to Feb. 15, 2025.

Combined Resolve is a recurring exercise designed by U.S. Army Europe and Africa to prepare a multinational brigade for support of NATO deterrence initiatives. The 3rd Brigade Combat Team, 10th Mountain Division from Fort Johnson, Louisiana, was the primary training audience, with Poland’s 11th Armored Cavalry Division operating as the high command.

The Transforming in Contact initiative, or TiC, utilizes new technologies and systems to enhance the Army’s war fighting readiness and ability to respond to crisis or conflict.

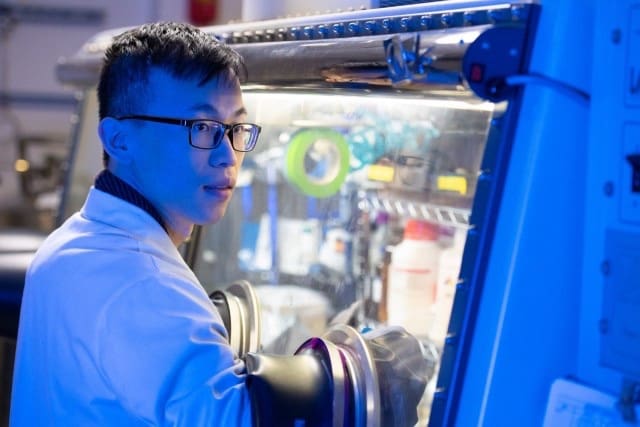

Leading up to the event, the 5th Mobile Public Affairs Detachment documented Soldiers from the 3rd BCT utilizing some of the new equipment. One of these featured systems was the Anduril Ghost X medium-range reconnaissance drone.

“These are mainly reconnaissance, surveillance and target acquisition platforms that are meant to find things in a named area of interest,” said Sgt. 1st Class Daniel Pariset, tactical unmanned aircraft system operator. “It is meant to be used at the battalion and lower levels to provide feedback to battalion commanders.”

“The previous system I used was the RQ7-B Shadow unmanned aircraft system,” said Pariset. “It was very limited by weather. However, these new systems are able to be utilized in rain, cold, heat and not have any limiting factors.”

The 3rd BCT, 10th Mountain Division is one of three Army brigades selected to train with TiC-focused systems. They deployed to Europe and immediately began fielding numerous TiC equipment, which are the first to be used in the European theater.

Prior to brigade’s participation in Combined Resolve, it was dispersed alongside NATO’s eastern flank.

“Throughout the course of the past six months we have received this new equipment trained on it and incorporated it into our collective training at echelon to get ready for Combined Resolve 25-1,” said Col. Joshua Glonek, commander of 3rd BCT, 10th Mountain Division.

Glonek goes on to note how his unit has done this, while deployed, in conjunction with other operational missions they have been tasked to conduct.

“The challenge is that we are dispersed throughout Europe and we’re doing this while participating in Atlantic Resolve. However, I think the point of the initiative is to be able to transform while a unit is deployed or potentially in a war,” said Glonek. “The way technology is rapidly integrating in society today, we have to be capable of receiving the newest technologies and very quickly getting our Soldiers proficient in how to use these systems, and that is exactly what we have been doing over here.”

The Army’s new technology provided to 3rd BCT is instinctual for Soldiers to operate compared to technology used in years past. This allows similar brigades to rapidly transform because it does not take long for Soldiers to become proficient operators with these new systems.

The technological areas that have made 3rd BCT far more capable than just six months ago when they arrived in Europe can be summed up in three elements: network capability, drone usage and increased mobility.

Network

“We have an integrated tactical network now that we use in the brigade which combines line of sight radios with the ability to communicate over LTE cell towers or through satellites,” said Glonek. “So we have a variety of transport options that we can use to communicate both over chat and voice and video through the battlefield so we’ve got a very effective communications systems and a network that we use.”

Drones

“We have fielded and are employing more drones over here at JMRC than other [Combat Training Centers] have used up to this point,” said Glonek. “We have drones at the company, battalion and brigade level that are conducting unmanned collection and targeting at echelon and so it’s making us far more lethal in our ability to find the enemy and rapidly employ fires against them.”

Mobility

“As a light infantry unit generally using some of the Army’s legacy vehicles, you’re limited in your ability to quickly maneuver around the battlefield, but we’ve received the Infantry Squad Vehicle which is allowing us to very rapidly reposition forces on the battlefield,” said Glonek. “We have received the Small Multipurpose Equipment Transport (SMET) that we can transport a lot of our sustainment supply. And we also have some of the next generation tactical vehicle which are experimental battery powered hybrid vehicles that the Army is looking at, so there are a lot of mobility options that we’ve been using.”

One key difference in how the Army is incorporating technology into formations today is that it is not looking at one specific piece of equipment to buy, train or employ as a staple system for years to come.

The Army is finding the best equipment available today and training to each asset’s full capability. Army leadership will continually and more rapidly evaluate its impact and seek to upgrade equipment based on front-line soldiers’ recommendations. This bottom-up formula is a key theme to the intended success of TiC. It is a cycle which reduces time spent pondering bureaucratic relevancy and focuses on genuine assets needed.

Off-the-shelf, high-quality technology at lowest cost available in real time is of much greater importance as they can be quickly incorporated into formations and employ immediate and positive effect.

“It has been a great opportunity to receive some of the most cutting-edge equipment that the Army is using and very rapidly integrating into our formations, and here we are testing it out in the most diverse combat training center,” said Glonek.

The JMRC is the Army’s only overseas, internationally-integrated CTC, allowing Soldiers and senior leaders to safely learn lessons in a realistic, regionally-relevant environment, unlike any other operated by the Army worldwide.

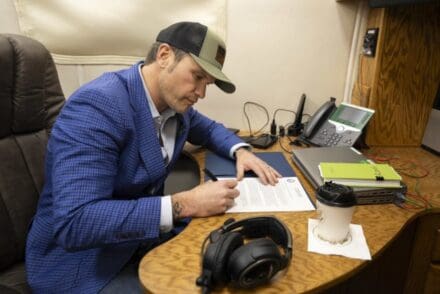

“There is an excitement in TiC that we are finally able to bring to Europe,” said Sgt. Maj. of the Army Michael Weimer. “Traditionally we wouldn’t give such new technology to Soldiers this early.

Traditionally we would grab a few Soldiers, allow them to experiment with the gear, get some feedback, then go back to do more research and development.”

Weimer goes on to describe how TiC has altered the Army’s business model, “because so much of this is commercial off-the-shelf, we are expediting our ability to learn. To give it to a full brigade like [3/10 Mountain,] we have stepped on the gas as we like to say, and we’re learning what’s working and what’s not and that helps us understand how to invest in the future.”

The Army has always been about its people. Now, it is merging the strength of its people with the functionality of technology.

Weimer said it best, “the character of war is changing at a speed we have never seen before. It’s unprecedented. The goal is to always make sure we are the premier war fighting element in the world.”

By SPC Thomas Dixon