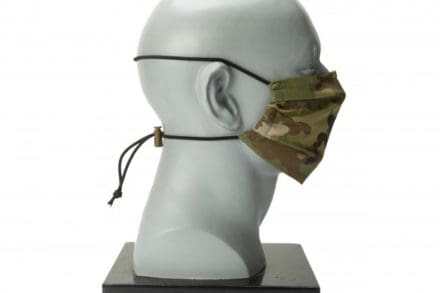

NATICK, Mass. – Dangerous times call for quick action, including rapid prototype development. With this reality in mind, the Combat Capabilities Development Command Soldier Center quickly designed face covering prototypes that comply with Department of Defense standards and meet Centers for Disease Control and Prevention requirements for protection against COVID-19, the disease caused by the Coronavirus.

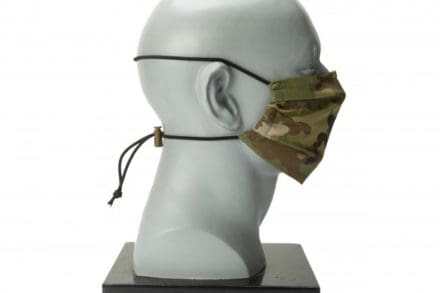

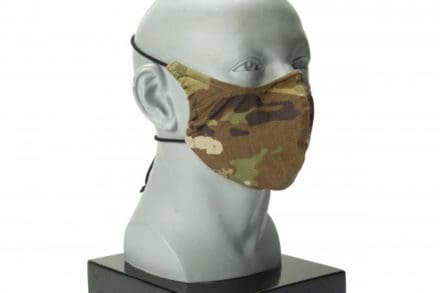

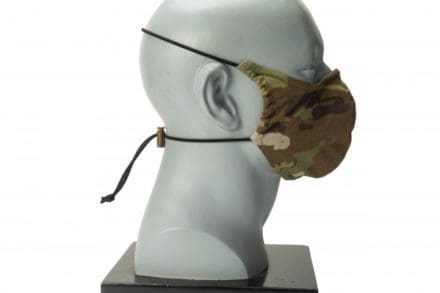

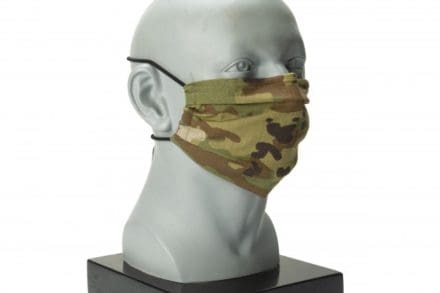

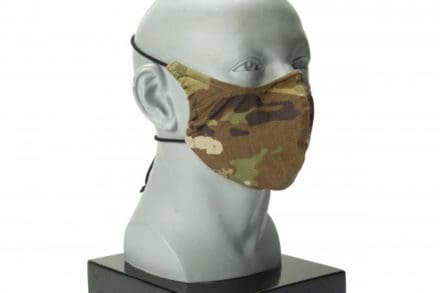

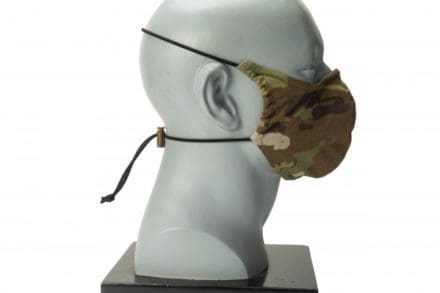

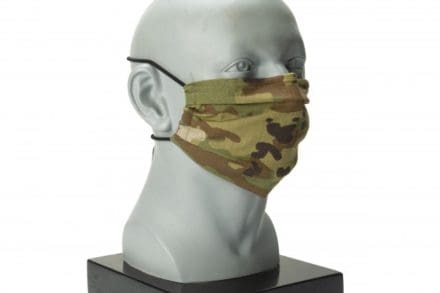

The CCDC Soldier Center, or CCDC SC, quickly developed six prototypes for face coverings, tested the prototypes, and chose one prototype that was highly rated by Soldiers for immediate development. CCDC SC also selected a second prototype, also well received by Soldiers, that has been further developed, coordinated with PEO Soldier, and will be a more permanent Army solution.

CCDC SC efforts focus on the research, development, and early engineering of the solution and building a Technical Data Package. The designs developed at CCDC SC have transitioned to its partners at PEO Soldier – Project Manager Soldier Survivability for production efforts. CCDC SC is also partnering with PEO Soldier on future iterations.

“During the pandemic, we must ensure that our Soldiers remain ready for any mission and that they are protected” said Douglas Tamilio, director of the CCDC SC. “Our Soldier protection and human factors expertise, combined with our testing and prototyping capabilities, enabled us to quickly develop an Army acceptable solution to the urgent requirement for face coverings.”

CCDC SC is committed to discovering, developing, and advancing science and technology solutions that ensure America’s warfighters are optimized, protected, and lethal. CCDC SC supports all of the Army’s Modernization efforts, with the Soldier Lethality and Synthetic Training Environment Cross Functional Teams being the CCDC SC’s chief areas of focus. The center’s science and engineering expertise are combined with collaborations with industry, DOD, and academia to advance Soldier and squad performance. The center supports the Army as it transforms from being adaptive to driving innovation to support a Multi-Domain Operations Capable Force of 2028 and a MDO Ready Force of 2035. CCDC SC is constantly working to strengthen Soldiers’ performance to increase readiness and support for warfighters who are organized, trained, and equipped for prompt and sustainable ground combat.

Annette LaFleur, team leader for the Design, Pattern and Prototype Team in the Soldier Protection and Survivability Directorate at CCDC SC, explained that CCDC SC “designers quickly brainstormed, sketched, patterned, and fabricated prototypes in one weekend – while material scientists, textile technologists and engineers coordinated the test and evaluation of potential materials.”

“The materials selection was a collection of past and current clothing development efforts, as well as sourcing readily available materials from industry,” said Molly Richards, a research chemical engineer at CCDC SC.

LaFleur explained that clothing designers on the Design, Pattern, & Prototype Team worked with load carriage experts at CCDC SC to rapidly develop an array of potential prototype systems that included six potential designs. CCDC SC’s Human Factors Team assessed the prototypes on Human Research Volunteers stationed at CCDC SC. The designs were given to Soldiers for feedback, a key component of all design efforts at CCDC SC.

“CCDC SC items, including the face covering, are developed with the Soldier from the beginning stages, so we can say it is ‘Soldier tested and Soldier approved,’” said Richards.

“The design selected needed no improvements,” said LaFleur. “We down selected to designs with the highest Soldier acceptance while considering other factors such as integration with helmets and eyewear as well as ease of manufacturing.”

The first design developed by CCDC SC is being fabricated in-house. CCDC SC specializes in prototype creation and is not a production shop. However, due to unprecedented circumstances caused by the pandemic, CCDC SC personnel are fabricating the first design, which was chosen because of its high acceptance with Soldiers and because it is easy to produce.

Richards explained that a small team of employees across three directorates are busy fabricating the first design with an initial quantity of 10,000 face covers to outfit Soldiers in basic training at Fort Benning, Georgia.

A second design, also highly accepted, has been further developed rapidly as a more permanent Army solution.

CCDC SC knowledge and expertise played an important role in the rapid design and development of the face coverings.

“We have a team of 10 talented clothing designers who work daily to design new and/or improved combat clothing, uniforms and individual protective items,” said LaFleur. “They have the military specific knowledge, skills, ability and creative drive. We collaborated with other CCDC SC subject matter experts in materials/textiles, human factors, anthropology for sizing; engineering technicians in the machine shop; and so many others in various disciplines. We need our Soldiers to remain healthy so they can remain optimized and defend our nation. At CCDC SC our priority is for the Soldier to not to be burdened by what they are wearing, so they can focus on their mission. For the face coverings, the goal is to meet the intent of the CDC and DOD guidelines for use of cloth face coverings when in public.”

“This effort was a natural fit for the expertise in the Soldier Protection and Survivability Directorate,” said Richard Green, Ph.D., director of SPSD at CCDC SC. “We have expertise in materials that enabled smart choices on the selection of materials to ensure the safety of the users. We have expertise in design to make sure that the items fit, function, and durability are appropriate for the intended use, and we have the expertise to provide our PM partners with technical data packages for further production. Mainly, however, we have a dedicated team of true professionals who were willing to come to work under restrictive working conditions and speedily execute this project because they understand the importance of meeting this need expeditiously. I could not be prouder of their effort.”

“CCDC Soldier Center has the expertise from design and prototyping to materials and textiles to react and execute quickly for the need for face coverings for the Soldier,” said Richards. “It has taken a team of people across directorates with a variety of expertise to execute quickly. Protection for our Soldiers is our top priority and taking measures to limit the spread of COVID-19 is essential during this unprecedented time.”