EGLIN AIR FORCE BASE, Fla. — Team members with the U.S. Army Medical Materiel Development Activity braved the arctic cold and hurricane force winds as part of environmental testing held July 11-15, 2024, at Eglin Air Force Base.

Working with industry partners and test engineers belonging to the U.S. Air Force’s McKinley Climatic Laboratory, the USAMMDA advanced developers put several arctic shelter kits and support systems through their paces. The equipment was exposed to a wide range of climate conditions in a lab setting to assess their ability to withstand some of the most brutal conditions found in an arctic environment, according to Jack Philpott, an assistant program manager with USAMMDA’s Soldier Medical Devices Project Management Office.

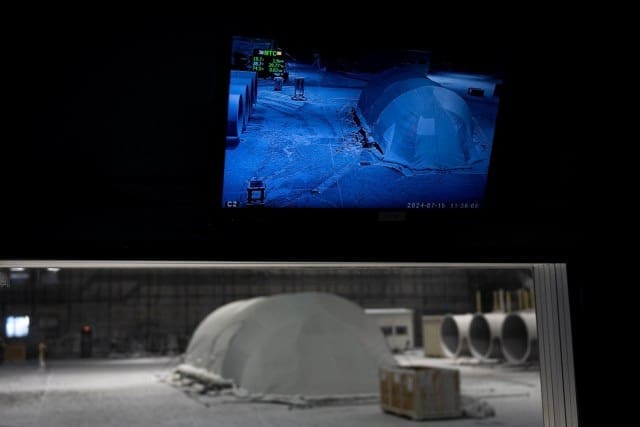

To assess the progress of the arctic shelter kit and support systems programs, the MCL test engineers and the SMD development team deployed four standard issue shelters inside the main test chamber, which is approximately 252 feet wide, 260 feet deep and 70 feet tall. The range of conditions across five days of testing — with temperatures as low as minus 60 F and winds as high as 80 mph — gave the development team precise data to measure the program’s strengths and areas for improvement, said Philpott.

“We are testing to make sure that the systems will even work under these extreme conditions. At such cold temperatures, screens and fabrics can crack, water will flash-freeze, oils and adhesives can dry and fail, and engines can potentially freeze and not function,” said Philpott, who manages the acquisition, support sustainment and refurbishment of hospital center medical shelters and water systems for SMD. “We also captured temperature data on the shelters, determining how well the systems will keep personnel and casualties warm, looking for leaks, cold spots, and other potential weaknesses and limitations.”

While the swampy Florida Panhandle in July may be an unexpected place for arctic testing, the McKinley lab is a key component of the U.S. Air Force 96th Test Wing’s capabilities in support of the U.S. Department of Defense. It comprises climate-controlled chambers that simulate nearly any weather and environmental conditions found around the globe, from temperatures as low as negative 80 degrees Fahrenheit to drenching monsoon rains to sandstorms with 60 knot winds.

The lab’s unique capabilities make it a perfect place to vet developing military equipment — like the USAMMDA arctic shelter kit and support systems — and give advanced medical developers a better understanding of how the equipment will withstand even the harshest environments in a controlled setting, according to Philpott.

“[MCL offers] size and scale. It’s the only environmental chamber large enough to deploy several shelter systems [at the same time]. Some will hold a single shelter, but only MCL allowed us to deploy all four kits and systems and a legacy ‘control’ shelter at once under identical conditions,” said Philpott. “It is critical to know ahead of deployment whether a system is capable of operating in every environmental condition that it may be deployed to. The battlefield is not the place to discover that a system is not able to withstand the extreme cold. Finding any [system] limitations while still in development will avoid costly test-fix-test cycles later in the acquisition cycle and avoid having a system rendered inoperable in the field.”

The week of testing took months of planning and partnering with stakeholders across the DOD and development industry. During the assessments, MCL engineers conducted a series of tests in the main chamber while USAMMDA’s development team and commercial partners observed and tracked the shelter kits and support systems for structural and environmental integrity, while keeping warfighter safety top of mind.

“We [also tested] to ensure that the shelters will not melt the permafrost under the tents, which could potentially create puddles that could leak into the shelters,” said Philpott. “Should a person step into a puddle at those temperatures, [it could] lead quickly to cold weather injury — frostbite can be instantaneous.”

As the DoD and U.S. Army continue to focus on modernization for future operations, including those in the arctic regions of the world, the USAMMDA SMD team is focusing on the unique challenges presented by extreme cold in austere environments. According to Philpott, the MCL test was an important step to ensuring the shelter kits and support systems are on track to meet the needs of frontline medical providers in the joint force.

“The data received here will help identify limitations that can be addressed in future design turns and help inform training and doctrine for these systems should they eventually deploy.”

By T. T. Parish