In an effort to continually improve our products, we have upgraded all wire forms in the MARK (Modular Attach Rail Kit) to a standard length with swaged tips. This means that MARK wire forms will allow more vertical adjustment and will be 100% drop-in compatible with 3M Peltor products out of the box. The new swaged tips are also 100% compatible with our SARA (Sordin Arc Rail Adapter) systems for use on MSA/Sordin-based headsets.

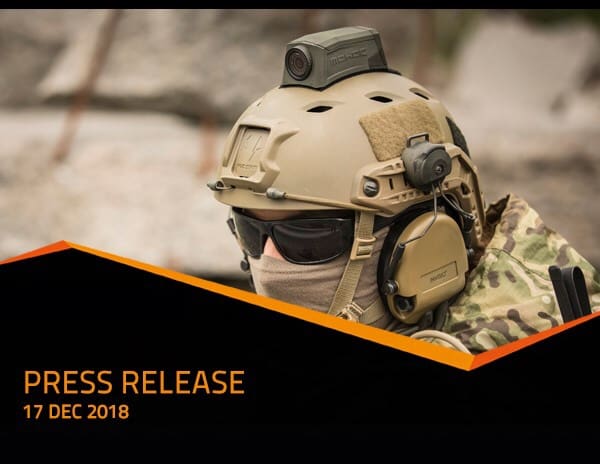

The MARK is the most complete system for direct mounting communication headsets and electronic ear protection to modern helmets. It is the smallest, lightest, and lowest profile attachment method for most popular headset systems used by professionals on the modern battlefield, including 3M Peltor, MSA, Sordin, Safaraliand TCI, TEA, and many more. Kits are available to interface with Genuine Ops-Core ARC, Crye Precision ARC, Revision, Team Wendy, and MTEK MLOK rail platforms. The wire forms of the MARK system are designed to put more inward pressure on the ear cups to improbe the seal. This can provide better hearing protection, electronic communication transmission, and overall fit of the helmet. The small hub leaves more helmet rail estate open for attaching other mission critical gear like lights, illuminators, cameras, etc.

MARK and SARA and built in the USA.

MARK Systems are available at www.unitytactical.com/shop/mark-kit.

SARA Systems are available at www.unitytactical.com/shop/sara-sordin-adapters.

Retrofit MARK wires for previously-purchased MARKs are available at www.unitytactical.com/shop/mark-wire-forms.