Revision Military is debuting two new products at this year’s SOFIC, the Expanded Batlskin Head Protection System, and the Prowler Military dermoskeleton which was developed in collaboration with B-TEMIA Inc.

Batlskin Viper Front Mount

Revision’s Viper Front Mount features an interchangeable center piece system which allows the user to swap the receiver component and utilize various NVG interface plates. The Front Mount also acts as the MPAS platform, allowing integration of the full line of Batlskin Viper components such as the Interlocking Long Rails and Mandible Guards.

Batlskin Viper Interlocking Long Rails

Revision’s Viper Interlocking Long Rails attach to the Front Mount and allow for quick and easy attachment of cameras, lights, and other head borne accessories. The rails are sized specifically to fit small, medium, large, or extra-large helmets. Now available to order.

Batlskin Viper High Cut Helmets

Revision’s Viper A1 and P2 High Cut Helmets are designed for optimal compatibility with communications headsets. The ACH-shaped Viper A1 High Cut is now available in all sizes. The Viper P2 High Cut will be available in early Summer.

Batlskin Viper Three-Position Visor

Revision’s Viper Three-Position visor clips into the Front Mount with a simple, one-handed movement, and can be worn in three configurations: locked, vented, or up. The Visor features high-impact protection and maximum field-of-view while remaining scratch, fog, and chemical resistant. An optional gasket provides a seal between the Visor and helmet. The Viper Visor will be available in early June.

Batlskin Viper Mandible Guards

Revision’s updated Mandible Guard provides best-in-class lower-face protection in a strapless design that’s lightweight and quickly attaches to the Front Mount without the use of tools. The Guard is easily tilted downwards in varying degrees from improved sight compatibility, eating, and drinking. Pressing the mandible against the chest resets it to its original position. The Mandible Guard will be available in early Summer.

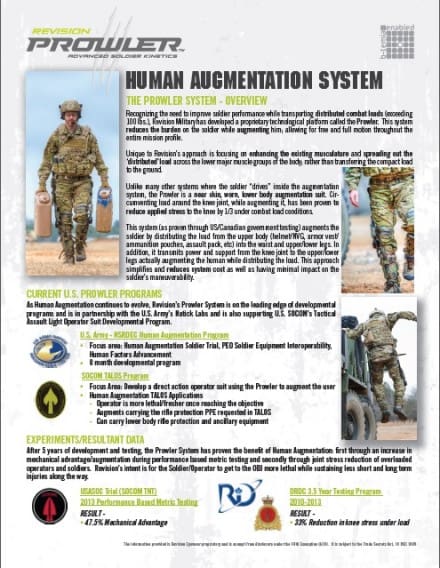

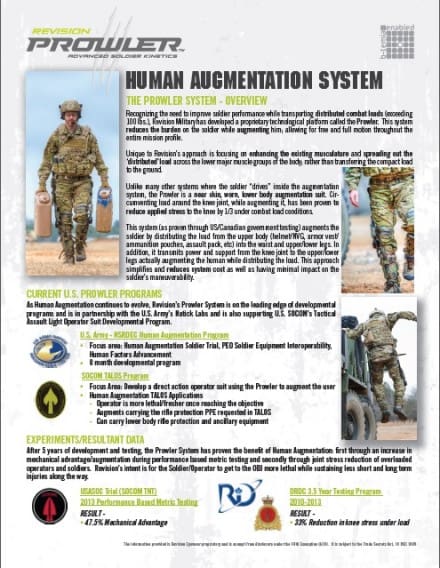

Prowler

Click to view .pdf

The B-TEMIA / Revision Prowler is a near skin, lower body motorized soldier protection device worn on both legs. It is designed to increase the metabolic energy reserve of soldiers while preventing short and long term musculoskeletal injuries. The Prowler distributes the load across the entire body from the upper body to the lower legs, circumventing the load around the knee joint which is proven to reduce applied stress to the knee by 1/3 under combat load conditions. The Prowler has been tested through the US Army NSRDEC Human Augmentation Program and SOCOM’s TALOS Program.

www.revisionmilitary.com