This is a joint release from Marine Corps Systems Command and the US Army’s Program Executive Officer Soldier. and is a good update to show you what is going on.

MARINE CORPS SYSTEMS COMMAND, QUANTICO, Virginia – In a series of ongoing efforts, Marine Corps Systems Command and the Army’s Program Executive Office – Soldier are collaborating to develop, test and deliver ever-better capabilities for Marines and Soldiers. These acquisition professionals are also closely aligned to ensure uniforms and personal protective equipment properly fit female and male service members in order to accommodate every individual Marine and Soldier.

The Cross-Service Warfighter Equipment Board and Improved Personal Protective Equipment System Integrated Product Team are just two of six established forums that give the services an opportunity to share technologies and develop service-specific and cooperative solutions to continuously improve equipment and uniforms for service members across all occupational specialties. In addition to these formal venues, the Corps and Army are also constantly collaborating behind the scenes.

“While the Marine Corps and Army collaborate formally within CS-WEB and IPPES IPT, we continuously participate in each other’s equipment testing exercises to collect and share research data.” said Army Lt. Col. Kathy M. Brown, product manager for Soldier Protective Equipment at PEO-Soldier. “Through these formal and informal methods we’re able to share new technology and ideas to keep our service members equipped with the best gear.”

Outcomes from Army/Marine Corps collaborative efforts span a spectrum of actions, including improvements for PPE, weight reduction, customization of uniforms and equipment to accommodate individual and unit missions, and organizational clothing and individual equipment development for extreme weather conditions.

One example of joint program success is the Enhanced Combat Helmet, fielded to both deploying Marines and Soldiers. Manufactured with the latest lightweight material technology, the helmet provides improved ballistic protection against specific small arms and fragmentation.

“Providing effective equipment that meets the needs of our service members is our highest goal,” said Charles Bell, a retired Marine and acting product manager for MCSC’s Infantry Combat Equipment. “There is a genuine, concerted effort to collaborate and to partner in development, acquisition and sustainment whenever we can.”

Cold weather clothing and equipment is another common cause. Developed by the Marine Corps and adopted by the Army, the Three Season Sleep System is designed for use in temperatures down to -13 degrees Fahrenheit in conjunction with designated cold weather clothing layers. Weighing less than two pounds, the sleeping gear is easy to pack, which allows service members to respond rapidly to changing field conditions.

“Adopting equipment between services is done frequently as we are constantly looking for ways to satisfy Soldiers’ and Marines’ needs,” said Army Lt. Col John Bryan, product manager for Soldier Clothing and Individual Equipment at PEO-Soldier. “The Three Season Sleep System is just one example.”

Lighten the Load

Together, the Army and the Marine Corps continue to focus on lightening the load for Soldiers and Marines, particularly when it comes to personal protective equipment. In 2010 the Marine Corps conducted a survey of Marines in conjunction with the Army’s Natick Soldier Research, Development and Engineering Center to assess sizing and weight of body armor and load bearing equipment. As a result, the services are partnering to develop the Plate Carrier Generation III (PC Gen III), a service-common vest that will provide better fit, comfort and mobility to Marines and Soldiers. The new prototype reduces the length of the protective vest by 1.25 inches; provides sports-graded shoulder straps to improve fit; and is 25 percent lighter than previous models.

“Both the Army and the Marine Corps are actively engaged in researching and developing a next-generation personal protective equipment solution that reduces overall weight; and optimizes the elements of size, bulk, fit and comfort to maximize mobility,” said Nick Pierce, the MCSC Team Leader for PPE, Load Bearing and Pack Systems. “The outcome will accommodate the comprehensive anthropometric differences between small and large-statured Marines and Soldiers – male and female – so that both services provide properly fitting PPE for the entire force.”

The PC Gen III is scheduled for multiple Limited User Evaluations during fiscal year 2017. Results will inform the requirements for the next-generation system.

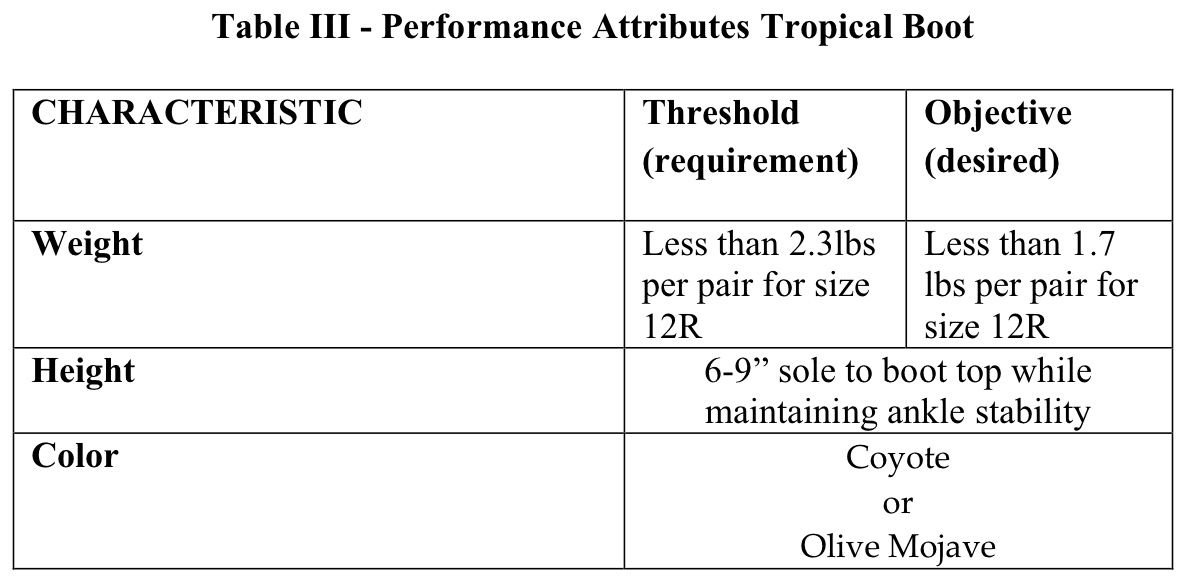

Tropical Environs

The services are working hand-in-hand to develop uniforms and boots for tropical environments. The result of that partnership was put to the test during August as the Marine Corps tests the prototypes during a LUE at the Jungle Warfare Training Center in Japan. The uniforms are made of lighter fabric and treated with permethrin to help repel insects. The boots were tested for improved moisture management and reduced drying time, without loss of durability or protection for the wearer.

The Army is also conducting user evaluations on its version of tropical weight materials and boots made for tropical environments.

“After each phase of tropical uniform evaluations with our Soldiers we send over our reports to the Marine acquisition team,” said Bryan. “If in the end the Army and the Marine Corps decide on the same items, great, but if information helps Marines find a better solution for their needs that works too.”

Collaborative initiatives like this aim to ensure Soldiers and Marines have the best products and capabilities to accomplish the mission. By engaging in a continuous free-flow of ideas, approaches and materiel improvements the services ensure they are aligned to streamline the acquisition process, reduce costs and provide common sustainment benefits.

Ongoing pursuits and success stories of the Army and Marine Corps individual equipment partnership:

– Flame Resistant Uniforms & Materials

– Spectral Mitigation and susceptibility reduction of PPE and uniforms

– Arctic Overwhites

– Protective Undergarments

– Enhanced Combat Vehicle Crewman’s Helmet

– Ballistic Base Layer/Combat Shirt

– Protective Eyewear

– ESAPI Ballistic Plates

– Extreme Cold Wx Boots

– Lightweight Exposure Suit

– Extreme Cold Wx Parka

– Windpro Fleece Jacket

“Anything we develop that the services are able to share has a ripple effect in terms of efficiency and cost. If the Army and Marine Corps can be sustained by the Defense Logistics Agency for the same systems—with the same National Stock Numbers—the result is an economy of scale that both services can leverage to reduce costs and simplify the acquisition and sustainment of multi-service common clothing and equipment,” said Bell.