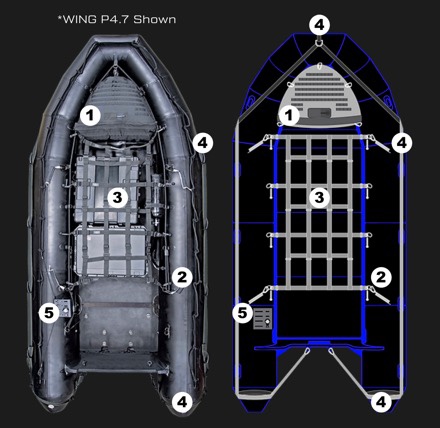

SOAL Marine Group, a defence contractor and manufacturer of electrified maritime mobility platforms, lightweight gyro stabilized systems, and specialist training, in partnership with The Wing Group (Wing Inflatables Inc.) and E.P. Barrus Ltd, has secured a five-year contract and will supply Military Inflatable Craft and related boat equipment, training, logistics and support to the Norwegian Armed Forces.

Johan Jorstadius, CEO & Partner of SOAL Marine Group, said: “This contract supports critical maritime operations with the ability to operate in both extreme cold and warm climates, and embeds the defence capabilities that we offer through the partnership between Wing, Barrus and SOAL.”

Wing is the largest supplier in North America of inflatable crafts for the defence market. This award, in combination with the UK Defence contract, sets a new international benchmark for the quality and performance that you can expect from a Wing craft. SOAL will be a strong partner for the management of the contract and integration of new technologies.

Andrew Branagh, CEO Wing Inflatables, said: “The Wing Inflatables team is a proud partner of SOAL Marine. Together we win the opportunity to deliver world- class military capable inflatable craft to the Norwegian Armed Forces.”

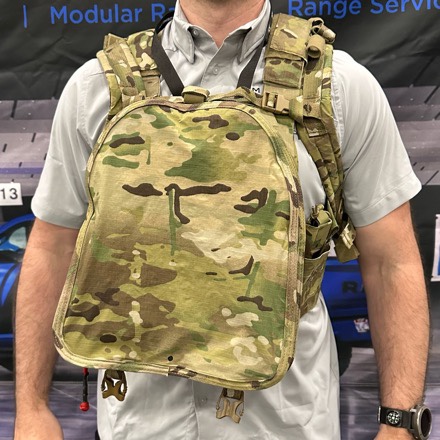

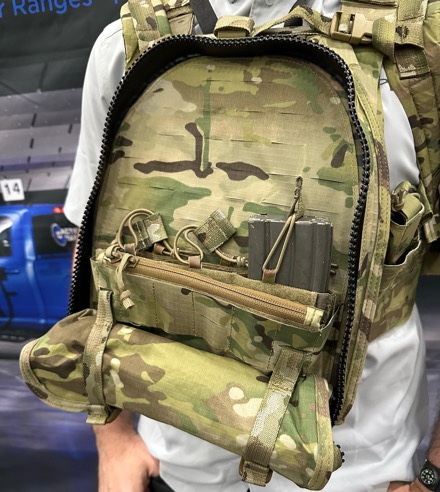

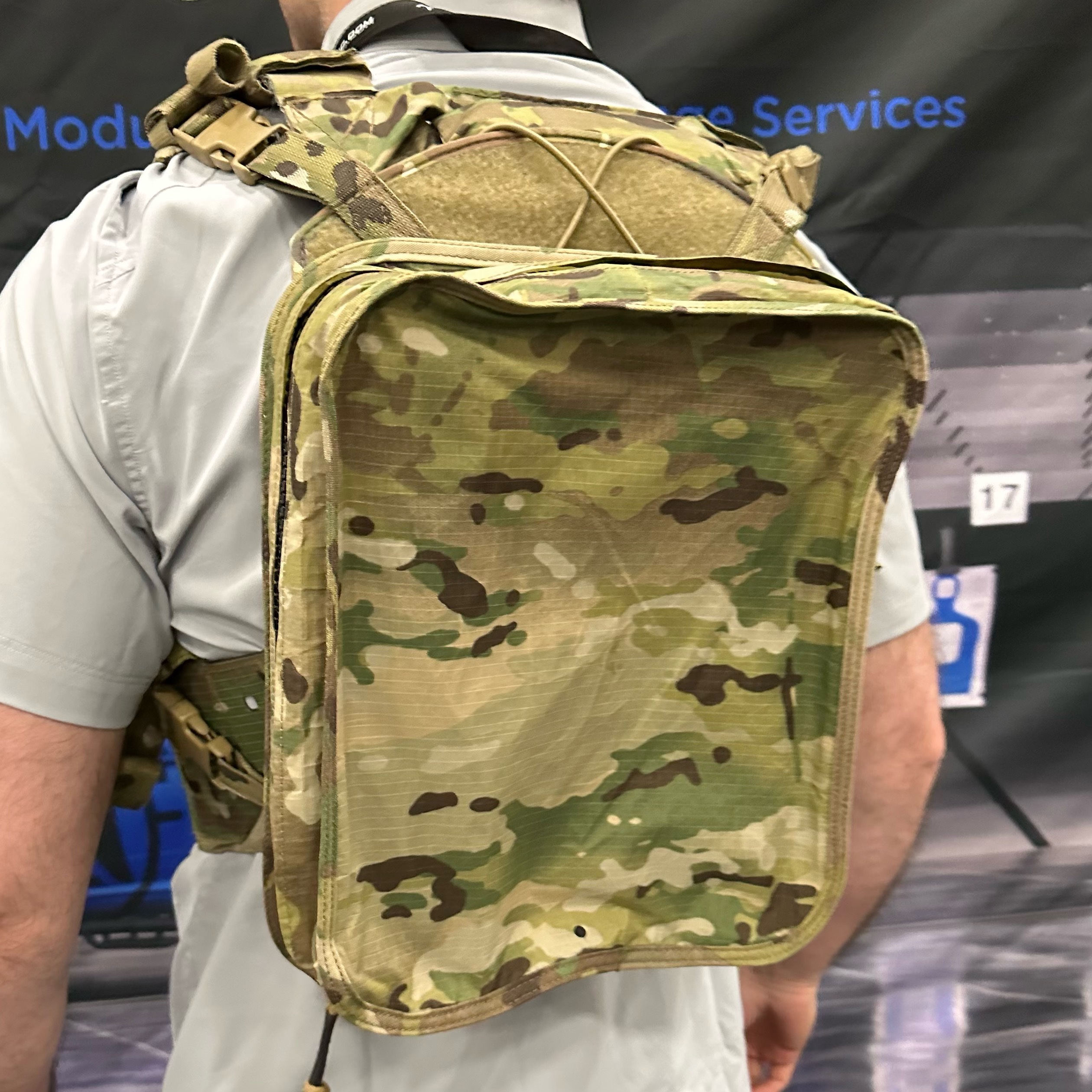

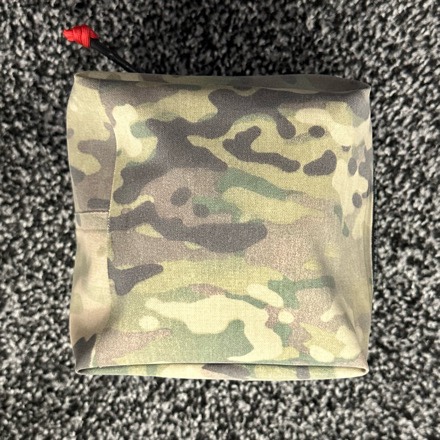

The Side Pouch is a 6″x6″ lightweight waterproof GP pouch intended to attach via PALS to the cummerbund. It incorporates a waterproof zipper and like the entire Raider line, sealed seams.

The Side Pouch is a 6″x6″ lightweight waterproof GP pouch intended to attach via PALS to the cummerbund. It incorporates a waterproof zipper and like the entire Raider line, sealed seams.