Every minute of every day, military personnel, law enforcement officers and security professionals around the world are putting their lives on the line to protect others. For these brave men and women, it’s just part of the job.

At DuPont, we believe that the brave deserve the best. We’re proud of our long history of helping to protect these everyday heroes and we are committed to providing new, innovative solutions as the threats they face continue to change and evolve.

That’s why we’ve added DuPont™ CoreMatrix™ Technology to our family of protection solutions, which includes innovative products such as DuPont™ Kevlar® for ballistic vests and shields, and DuPont™ Tensylon® for hard armor applications.

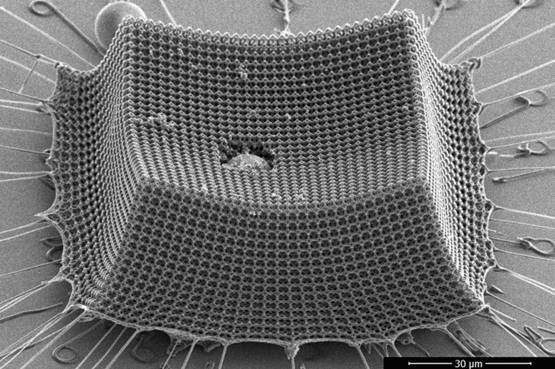

DuPont™ CoreMatrix™ Technology enables the lightest, most flexible ballistic solutions that meet National Institute of Justice (NIJ) standards for enhanced durability. This globally patented technology, available exclusively from DuPont, uses needle punching technology to infuse fiber in the Z direction, creating a monolithic structure used in today’s most advanced body armor packages.

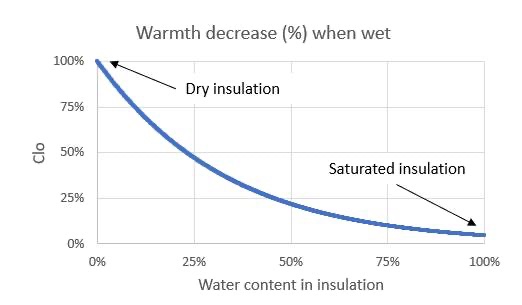

DuPont™ CoreMatrix™ Technology disperses the impact energy 360 degrees, significantly enhancing ballistic performance compared to traditional woven structures that are stitched together and primarily disperse energy in the X and Y planes.

“By adding this third dimension of protection, DuPont™ CoreMatrix™ Technology combined with DuPont fiber technologies provides unmatched strike face performance while delivering superior protection against edge shots, multi hits and fragment threats,” said Steven LaGanke, Global Defense Segment Leader, DuPont Water & Protection.

This superior ballistic performance allows for lighter weight solutions, which are more comfortable to wear. Hybrid package solutions made with DuPont™ CoreMatrix™ Technology also offer increased flexibility and a softer feel against the body, further enhancing comfort.

“When it comes to choosing soft armor or bomb suits, the level of protection against ballistic threats always takes priority over the wearer’s comfort. After all, it could be a matter of life or death,” noted LaGanke. “With DuPont™ CoreMatrix™ Technology, there are no tradeoffs required. That’s why we believe it is a paradigm shift in ballistic protection.”

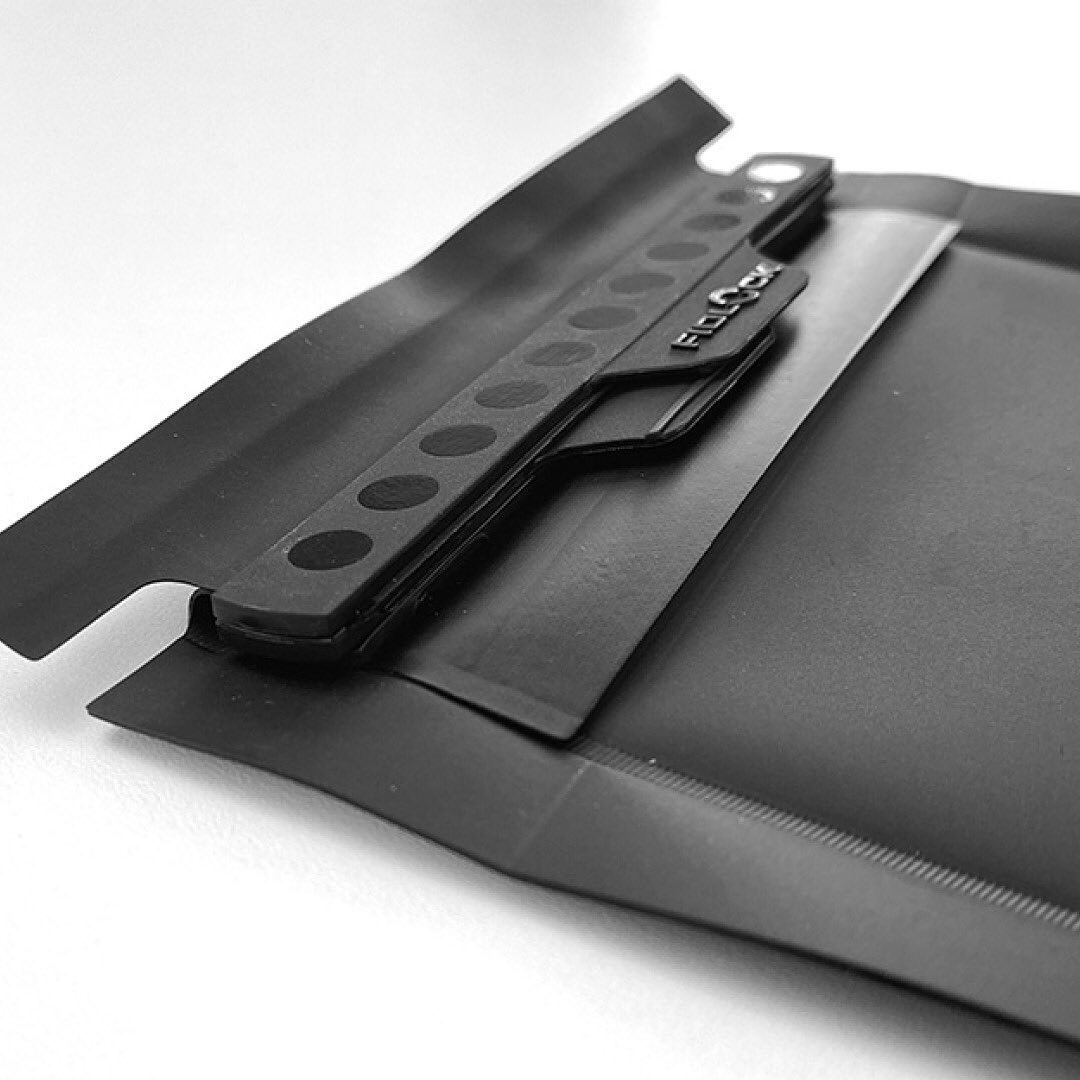

In addition to enabling comfort without compromise for wearers, hybrid package solutions made with DuPont™ CoreMatrix™ Technology mean ease of manufacturing. These hybrid fabric solutions are available in different layer counts and yarn deniers so there are fewer SKUs to keep in inventory and there is no need for layer counting or complex design. Manufacturing time is also significantly reduced because a simple “stack & tack” method is used, and no labor-intensive quilt stitching is required.

DuPont™ CoreMatrix™ Technology combined with DuPont fiber technologies opens a world of possibilities. It gives manufacturers greater design freedom than ever before to deliver the best, most flexible and lightest weight solutions available to protect those who put their lives on the line to protect others.

To learn more about DuPont™ CoreMatrix™ Technology, visit www.dupont.com/brands/core-matrix