Rokon has introduced the Universal Accessory Rail! With options for the front and rear, UAR can add up to 18 threaded mounting points for accessories to outfit your Rokon for any job.

www.rokon.com/bikes-gear/accessories/universal-accessory-rail

Rokon has introduced the Universal Accessory Rail! With options for the front and rear, UAR can add up to 18 threaded mounting points for accessories to outfit your Rokon for any job.

www.rokon.com/bikes-gear/accessories/universal-accessory-rail

Over the course of this winter, “The Originals” of 10th SFG(A) have conducted a wide variety of cold weather and mountaineering training both at their home base of Ft Carson, CO and in at various locations in Europe.

What the heck, it’s Sunday, a great time to watch videos. This one of the Textron optionally-manned M5 Ripsaw electric tank shows you what it can do thanks to robotic controls. Yep, that’s a UGV coming out of the front of the Ripsaw. It’s a robot that births robots.

Patria, a global market leader in the production of armoured wheeled vehicles, have been selected with their 6×6 platform to be part of a joint programme to develop sustained mobility enhancement for the Finnish and Latvian Armies. Alcon Components Ltd, world-class specialists in brake and clutch systems, is the principal supplier of braking components for Patria’s heavy armoured vehicle range, and specifically the Patria 6×6.

Alcon has worked closely with Patria to determine the specific requirements aligned to vehicle specification, usage profiles and operating environment; developing a bespoke braking system to match the needs of high-performance defence vehicles. With the exceptional performance of Patria’s wheeled vehicle range creating conditions close to that of a rally car in terms of disc and pad temperature cycling, Alcon were able to draw on their pedigree of providing braking solutions for the top echelons of motorsport to develop exclusive calliper and disc mounting concepts for Patria; a fusion of those seen on heavy commercial vehicles and high-performance motorsport.

The Patria 6×6 is acknowledged as being unrivalled in performance and mobility, setting new standards for all future armoured wheeled vehicles. Reliability is underlined by the multitude of commercial components used in the vehicle. Commercial components, long life-span and easy maintenance make the vehicle extremely cost-efficient; ideally matching the Finnish-Latvian programme’s aim to develop a common armoured wheeled vehicle system with enhanced mobility, cost-efficiency, interoperability and security of supply.

Alcon braking solutions have been sought out by some of the world’s finest defence industry vehicle OEMs. Amongst 18 defence and security equipment OEMs currently using or assessing Alcon systems, as well as Patria, Supacat, the designers of the Jackal, BAe, Ricardo and Jankel have turned to Alcon to deliver bespoke braking systems that fully meet the demanding requirements of the challenging, high-performance, modern-day battlefield.

Mr. Janne Räkköläinen, Vice President Vehicles, at Patria Land said: “Our 6×6 vehicle is designed to be operated in all conditions and it needs to deliver the solid performance throughout the various missions and operations. In addition to the performance, braking systems are safety critical elements of the vehicle so the complete reliability and fulfilment of requirements are top priority for us. We know we can rely on Alcon’s support and performance”.

Jonathan Edwards, Group Sales Director at Alcon said: “Alcon’s previous selection by Patria is an unqualified confirmation of Alcon’s status as a company that provides the finest bespoke braking systems to the global defence markets. We’re delighted that the Patria 6×6 has been selected for this programme and we look forward to a continued strong relationship with Patria as the programme evolves.” He added: “It is a key strategic company aim for Alcon to become the first-choice braking system supplier to defence vehicle companies across the globe. This recent announcement underlines our ability to deliver and become exactly that.”

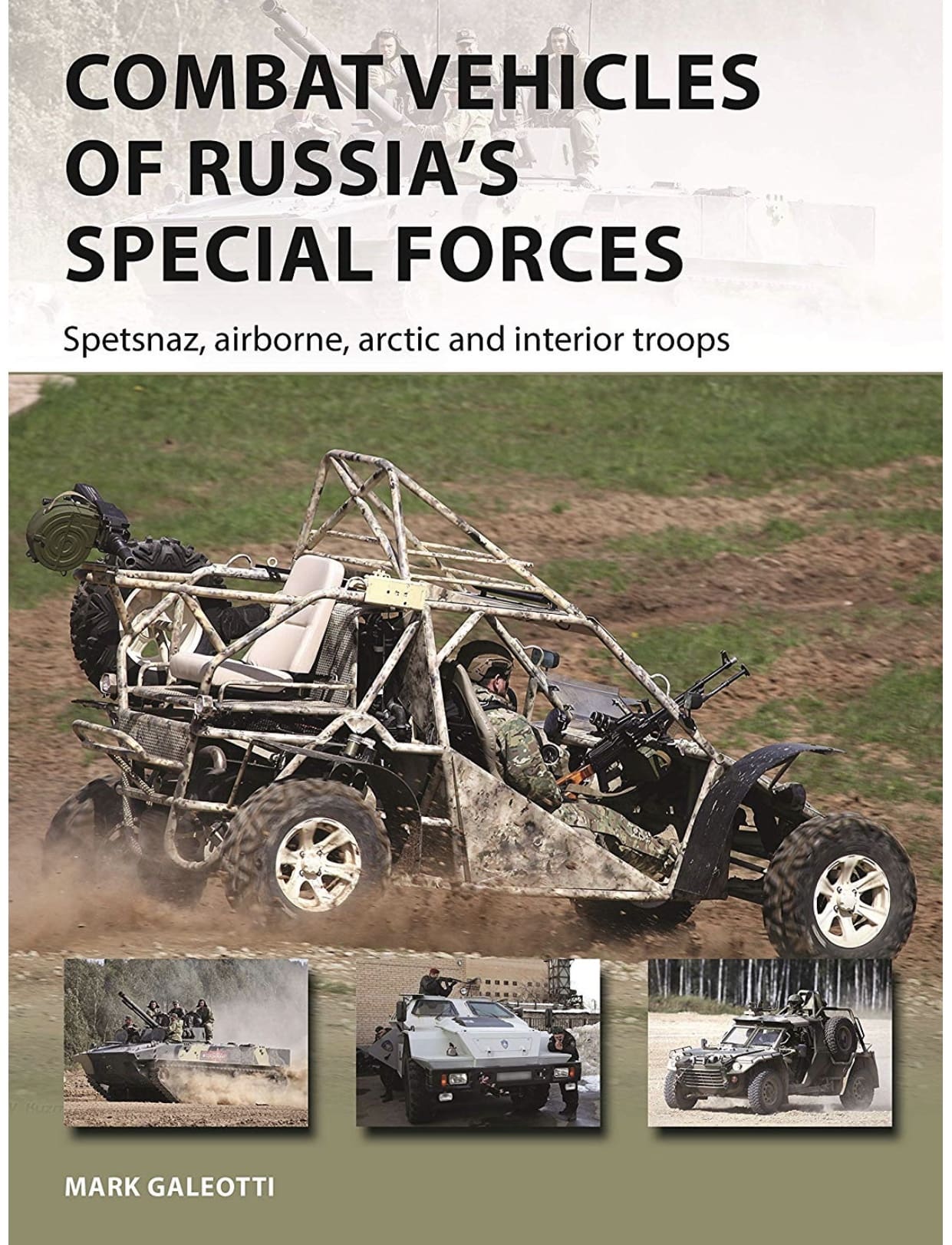

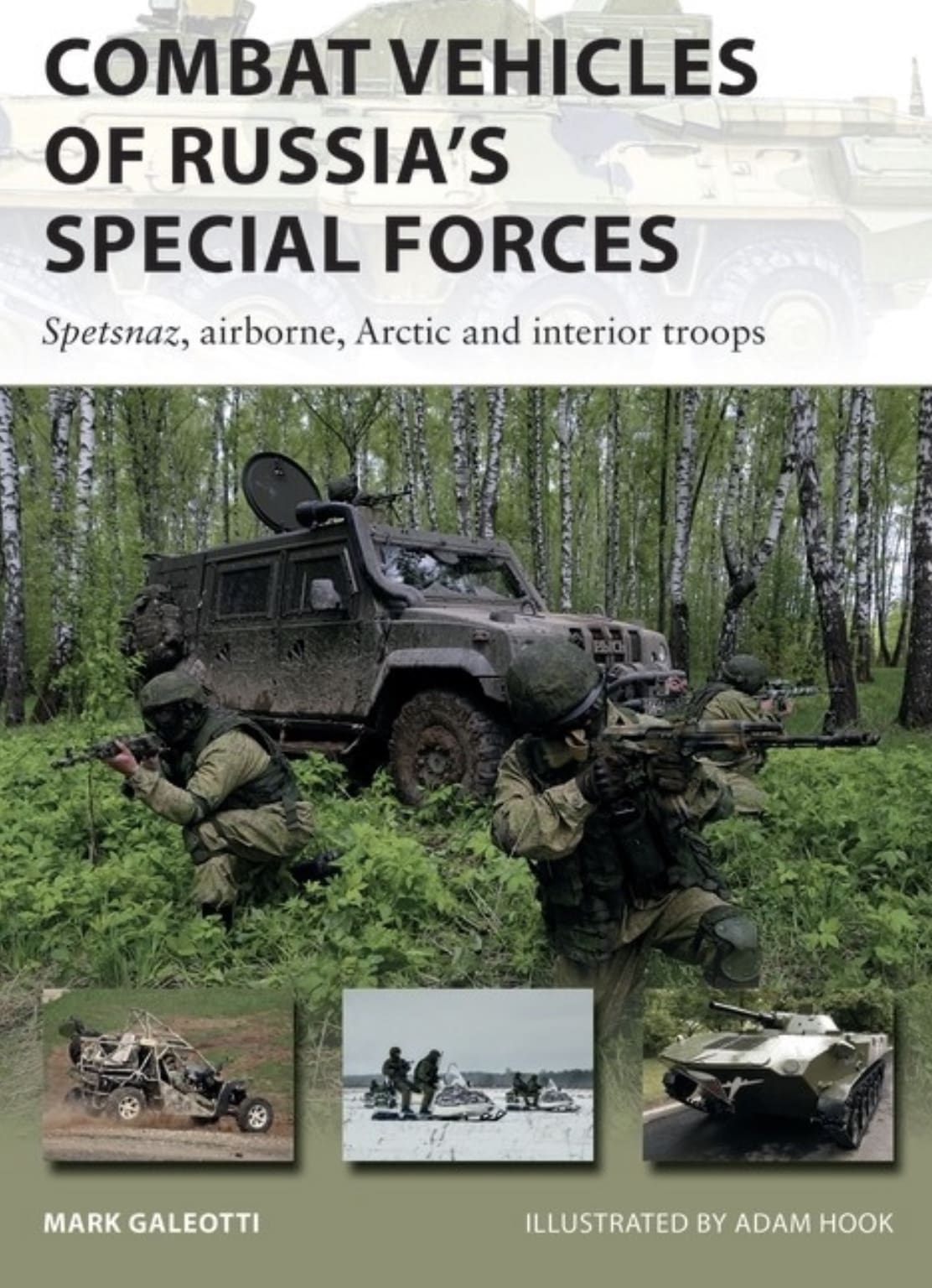

The upcoming “Combat Vehicles of Russia’s Special Forces” from Osprey Publications will feature Spetznaz, Airborne, arctic and interior troops vehicles. It is written by Professor Mark Galeotti.

These books are always excellent general references and I recommend them for any library.

Russian SOF are being outfitted with a combination of armored vehicles and light all terrain vehicles for mobility regardless of the environ they’ll be operating in.

The contents give you an idea of what will be covered.

Introduction

The Spetsnaz: Whatever They Need

The Airborne Troops: By Air and Land

The Naval Infantry: Finding Their Sea Legs

Specialised Forces: War and Peacekeeping

Security Forces: Hurricanes And Punishers

Prospects For The Future

Further Reading

Index

It seems they have changed recently the cover, with the new version seen above. This title is expected to be released on May 26, 2020.

ALLENTOWN, PA (Feb. 13, 2020) – Mack Defense has assembled the 1,587th and final truck for the Medium Support Vehicle System (MSVS) Standard Military Pattern (SMP) program. The truck rolled off the assembly line on Feb. 13 in Saint Nicolas, Quebec in front of a select group of dignitaries, military officials and Mack Defense employees.

Mack Defense has assembled the 1,587th and final truck for the Medium Support Vehicle System (MSVS) Standard Military Pattern (SMP) program. The truck rolled off the assembly line on Feb. 13 in Saint Nicolas, Quebec in front of a select group of dignitaries, military officials and Mack Defense employees. Pictured from left to right are MSVS trucks in Cargo, Load Handling System (LHS), Material Handling Crane (MHC), and Material Repair Truck (MRT) variants.

Mack Defense has assembled the 1,587th and final truck for the Medium Support Vehicle System (MSVS) Standard Military Pattern (SMP) program. The truck rolled off the assembly line on Feb. 13 in Saint Nicolas, Quebec in front of a select group of dignitaries, military officials and Mack Defense employees. Pictured from left to right are MSVS trucks in Cargo, Load Handling System (LHS), Material Handling Crane (MHC), and Material Repair Truck (MRT) variants.

“Mack Defense is proud to have completed the build out of these trucks, and we look forward to continuing the program and supporting the more than 1,500 MSVS trucks that will be in service with the Canadian Armed Forces,” said David Hartzell, president, Mack Defense. “This program demonstrates the global reach and collaboration Mack Defense is capable of.”

Mack Defense is part of the Volvo Group and leveraged the Group’s large industrial footprint and global capabilities to engineer and produce the MSVS SMP trucks. Before final production took place at a Prevost facility in Saint Nicolas, additional work was completed at facilities located in Bourg-en-Bresse, Marolles, Blainville and Limoges, France. The MSVS SMP program was coordinated through Mack Defense headquarters in Allentown, Pennsylvania.

In addition, Mack Defense called upon several key Canadian partners including Dumur Industries Ltd., EODC, Inc., Marshall, Craig Manufacturing and Link Suspensions of Canada (Raydan Division) to contribute to the project.

Mack Defense was awarded two contracts in 2015 valued at $725 million CAD by the Department of Public Works and Government Services Canada on behalf of the Department of National Defense. The contracts called for Mack Defense to deliver more than 1,500 8×8 MSVS SMP trucks, including variants such as cargo, material handling cranes, load handling systems (LHS) and mobile repair trucks (MRT).

The off-road section of GAOS is filled with various options. These two 6-wheeled vehicles stood out. In both cases that third axel offers increased payload and ground contact.

The Defender 6×6 DPS is a side by side machine with a traditional steering wheel.

It incorporates a Rotax 976cc V-twin producing 82 horsepower and 69 foot pounds of torque. It’s can carry up to 1,000 pounds and has a towing capacity of 3,000 pounds.

The bed can be opened up for larger sizes loads.

The Outlander Max 6×6 XT 1000 ATV features a 1000 Rotax V-Twin engine which produces 82 horsepower. It has a carrying capacity out of Additionally, there is a factory installed 3,000 pound WARN winch.

If there’s a drawback to the Outlander Max, it’s the wide turn radius due to the handlebar steering and extra axel.

The bed can be tilted to dump hauled material.