During a press conference earlier this week at Ft Riley, Kansas, the Army’s PEO Soldier announced that they have begun to upgrade M4 carbines to the M4A1 configuration beginning with the 1st Infantry Division. The process will convert 500,000 of the weapons at a cost of $120 Million over the next five years with the fielding plan being controlled by Department of the Army. This press conference also served to dispel rumors that I have heard that they Army plans to pure fleet to the M4A1 configuration and upgrade its M16A2/A4 currently used by many non-Combat Arms Soldiers. They aren’t, and nothing is currently planned for the existing M16s.

“Upgrading M4s to the M4A1 configuration will deliver increased sustained rate of fire, durability, and enhanced ergonomics for the Soldier,” said Lt. Col. Shawn Lucas, PM IW. “The Army’s priority is to maintain the best equipped land force in the world, and to ensure it is postured to fight and win any conflict.

“Looking to the future, the Army will continue to monitor industry and government advancements in small arms to inform future requirements for leap-ahead technologies in range, accuracy, lethality and reliability,” Lucas added.

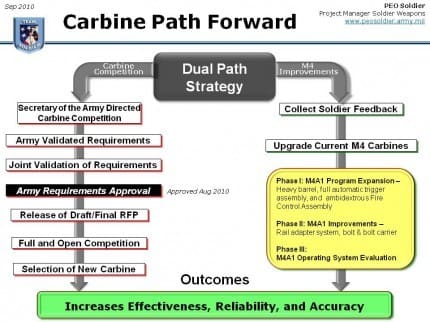

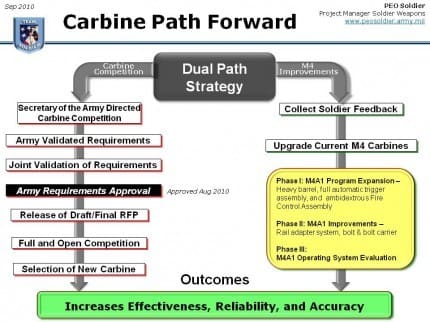

It’s important to note that these aren’t the first M4A1s in the Army. SOF troops have been wielding the weapon since 1994 as part of the SOPMOD (Special Operations Peculiar Modification) program and some Army units were fielded M4A1s in 2012. This implementation of the Dual Path Strategy that offers an incremental upgrade to existing carbines, was one of two plans to improve the lethality of the Individual Soldier. The other leg of the Dual Path Strategy was the Individual Carbine program which was halted last year after failing to identify any significant improvement over currently fielded systems.

Of note, is the claim by PEO Sergeant Major, CSM Doug Maddi, that the M4A1, when used with the new M855A1 ammo, offers “58 basic loads mean rounds between stoppages.” That’s pretty impressive, considering a Soldier Basic Load of Ammunition is 210 rounds. They’re getting upwards of 12,000 mean rounds between stoppages.

The M4s will receive a new, heavier barrel, ambidextrous safety and a conversion from 3-round burst to full-auto fire. Technicians from Anniston Army Depot, Alabama and TACOM are performing the Modification Work Order upgrades on site at Ft Riley. They are moving along at a pretty good pace, upgrading about 300 Carbines per day. The extent of the MWO can be seen in the graphic above.

Contracts for the new components required for the upgrade were awarded in March. Both the M4 Replacement Barrel and Front Sight Assembly (Heavy Variant) are from Colt Industries, owner of the M4 patent. OG TECHNOLOGIES INC and Manufacturing Support Industries, Inc are providing the M4 Fire Control Selector Assembly.

The maintenance team will install pre-built upper receiver assemblies, replace the trigger assemblies and install ambidextrous selector switch. The old M4 upper receivers will head to Anniston to undergo inspection where some will become part of future MWO kits. In addition to installing the new parts, the team will also use a laser engraver to alter the weapon’s designation to M4A1 and add “Auto” markings to the lower receiver in place of the current “Burst” designation.

But this is just stage one, with a Block II MWO coming in the future. Additional upgrades the Army plans to incorporate into the M4A1 include a new Modular Handguard, Bolt Carrier Group and possibly a Match-Grade Trigger. The Army also continues to consider the wider use of suppressors.

In the end, you can look at this one of two ways. On one hand, the Army’s Dual Path Strategy was a good investment and is improving the Soldier’s Carbine. I applaud them for doubling down to make sure that a great weapon was made even better. On the other hand, the Army is just now standardizing what SOCOM has had since 1994. The photo below depicts an Army Special Forces NCO in the mid-90s equipped with an M4A1 and looking at his equipment it almost gives you a feeling of nostalgia. It kind of feels like an opportunity lost.

The PIP was pretty conservative and didn’t leverage much of the improved small arms technologies we’ve seen from industry over the last decade, since the sunset of the so-called Assault Weapons Ban which stymied innovation in the US firearms industry from 1994-2004. Hopefully, the Army will continue to engage industry and provide additional enhancements to the Soldier’s most basic weapon; his Carbine.

(Thanks to PEO Soldier’s PAO team for the photos and to the participants in the press conference: LTC Shawn P. Lucas, Product Manager Individual Weapons, Picatinny Arsenal, NJ, CSM Doug Maddi, PEO Soldier Command Sergeant Major, Ft. Belvoir, VA and CW3 Charles Havner, 299th 2nd Brigade, 1 Infantry Division, Ft. Riley Kansas .)