I’ve spoken with quite a few companies as of late about opportunities like this. If you are innovating then this is one of many ways to get your ideas in front of the acquisition community. SOF has traditionally been the fountainhead of innovation within DoD and I recommend that you take a look at this.

The Program Executive Office Special Operations Forces Warrior (PEO-SW) will be holding “Industry Collaboration Day” on Thursday, November 14, 2013 from 0800-1700 at the Embassy Suites Hotel Tampa Airport/Westshore, 555 N. Westshore Blvd, Tampa, FL 33609. The objective of this collaboration day is to enhance PEO-SW team collaboration with industry in support of the SOF Operator. Industry is invited to submit nominations in the form of two-page unclassified white papers addressing innovative technologies as outlined in commodity/capability areas listed below. The intent is to share ideas that accelerate the delivery of innovative capabilities to the Special Operations Forces (SOF) warfighter.

Ground Mobility

• Passive noise cancellation for engines

• Reduced visual signature (eg camo, 3D camo) paint treatments

• Lightweight (thin)Transparent Armor (GMV 1.1 / NSCV)

• Rapid Emergency Egress doors

• Amphibious assault LTATV

• Purpose built armored NSCV

Visual Augmentation Systems

• Head-mounted Devices for:

-Seamless transition from low light to high light (transition time)

-Seamless transition to weapon sight while wearing NODs

-Jamming enemy image intensifier

-Multi-spectral night vision

-Increased field of view without loss of resolution

-Import/export data or images

• Hand Held Devices:

-INOD compatible spotter scope capability

-Capture biometric data for facial recognition

-Adaptive multispectral night vision

-Import/export data or images

-Sensing wind speed/direction to 1500 – 2000m; calculate ballistic offsets

-Reduce size, weight and power for smaller pocket configurations

• Weapon Mounted Device:

-Wireless universal power source rail system

-Capturing biometric data for facial recognition

-Multispectral night vision

-Wireless Import/export data or images

-Sensing wind speed/direction to 1000 – 2000m; calculate ballistic offsets

-Range dependent disturbed reticle sight

-Adaptive multispectral night vision

-Reducing complexity, weight, and bulk

-Cost and complexity reduction

• Fires / LASERs:

-Non-laser marking device or passive target engagement.

-Incorporation of terrestrial and celestial navigation into Joint Terminal Attack Controller (JTAC) equipment

-Integration of INS equipment with minimal start up time

-JTAC Simulation equipment

-Long Range image data transmission

-Non-proliferated band (out of band) illuminator/laser/sensor

-Non-laser marking device or passive target engagement.

-IR laser illuminator adjustable for short to long range use in one package

-Reducing complexity, weight, and bulk

-Cost and complexity reduction

Weapon Systems

• Round count and Tracking for weapon maintenance, barrel change

Ammunition/Demolition

• Polymer Cased lightweight ammo

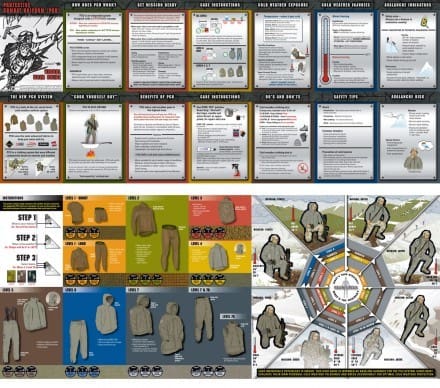

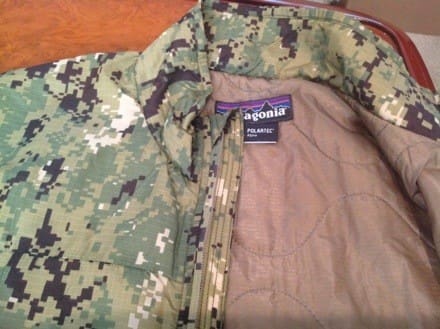

Soldier Protection, Survival and Equipment Systems

• Hard Armor

-Lightweight

-Modular

• Special Operations Eye Protection

-Improved Anti-Fogging

-RX Options

-Improved Laser Protection

-Transition Lenses

• VAS Mounts

-Low Profile / Lighter Weight

-Interoperable with Multiple VAS Systems

• Website development for Special Operations Personal Equipment Advance Requirement (SPEAR) Asset Management

Tactical Combat Casualty Care Medical Systems

Find, Fix, Finish, Exploitation and Analyze

Read all of the details on what the day will entail and how to submit at www.fbo.gov.