New Tactical Power and Data Communication Solution Aims to Extend Equipment Runtime, Lighten Loadouts, and Simplify Comms Kits Reconfiguration.

Washington D.C. (Oct 14, 2024) – OTTO and Freedom Atlantic are proud to announce the commercial launch of WedgeX™, a revolutionary advancement in tactical communication technology. Designed to transform how warfighters manage their comms equipment, WedgeX introduces a new paradigm in the radio power/datawedge market, offering unparalleled adaptability, simplicity, and extended run-time for frontline operators.

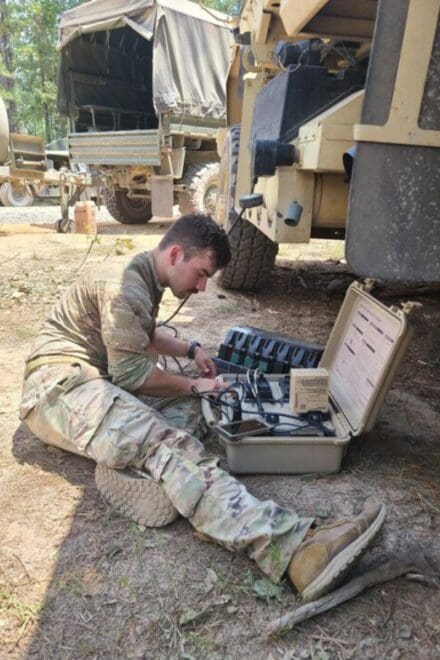

As warfare evolves and battlefields become increasingly decentralized and unpredictable, warfighters face the daunting task of manually optimizing their communication kits to meet rapidly changing conditions. Traditional systems require significant time and attention for equipment management, detracting from the critical focus needed for mission success and survival.

WedgeX addresses these challenges by automating and streamlining comms equipment management. Featuring an advanced modular design, WedgeX enables soldiers to quickly reconfigure their kits based on mission requirements, significantly reducing the physical and cognitive load associated with managing multiple devices and adapters.

“WedgeX is a game-changer for the modern warfighter,” said Ken Jillson, Chief Technology Officer at Freedom Atlantic. “From the start, our mission was to create a communications solution that adapts to the soldier—not the other way around. The WedgeX system actively monitors how soldiers use their equipment and intelligently adjusts power distribution to ensure their most critical gear is operational when they need it most. Our goal is to keep warfighters mission-focused, eliminating the distraction of managing their gear.”

The WedgeX system features a suite of game-changing capabilities:

• Automatic Device Run-time Management: Utilizes advanced algorithms to monitor and manage equipment run-time, prioritize critical devices, and conserve battery life with features like power scavenging and temperature-aware charging.

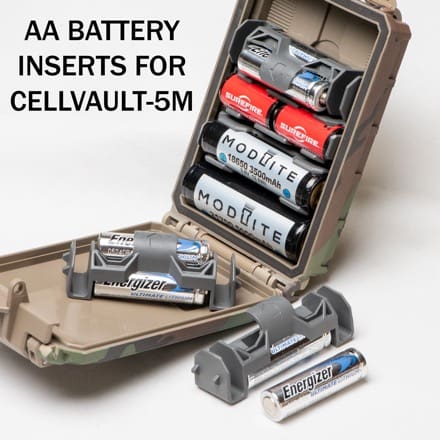

• Multi-Mission Modularity: A flexible design supporting various mission profiles and power needs, from short-term to extended operations.

• Simplicity: Seamlessly integrates data from tactical devices into a unified, configurable data hub and power controller, eliminating the need for extra cables and adapters.

“WedgeX represents a significant leap forward in tactical communication systems,” stated Dan Stanek, President of OTTO. “By offering automatic run-time management and a streamlined configuration process, WedgeX enhances operational efficiency and soldier survivability. It’s designed to meet the evolving demands of modern combat.”

The WedgeX System comprises two primary components: the WedgeX Radio Power Adapter and the SideLink Modular Radio Hub Adapter. The Radio Power Adapter, installed between the radio and battery, supports existing tactical radios with a MIL-STD twist-lock bayonet-style battery interface. The SiswLink connects the WedgeX, radio data interfaces, ATAK EUD, and external data devices, ensuring seamless integration without the need for additional unnecessary external devices.

Co-developed by OTTO and Freedom Atlantic, WedgeX provides warfighters with a comms overmatch by redefining tactical radio power and data distribution. This innovative solution offers rapid adaptability, extended run-time, and lighter loadouts.

Contact OTTO today for more information or a demonstration.