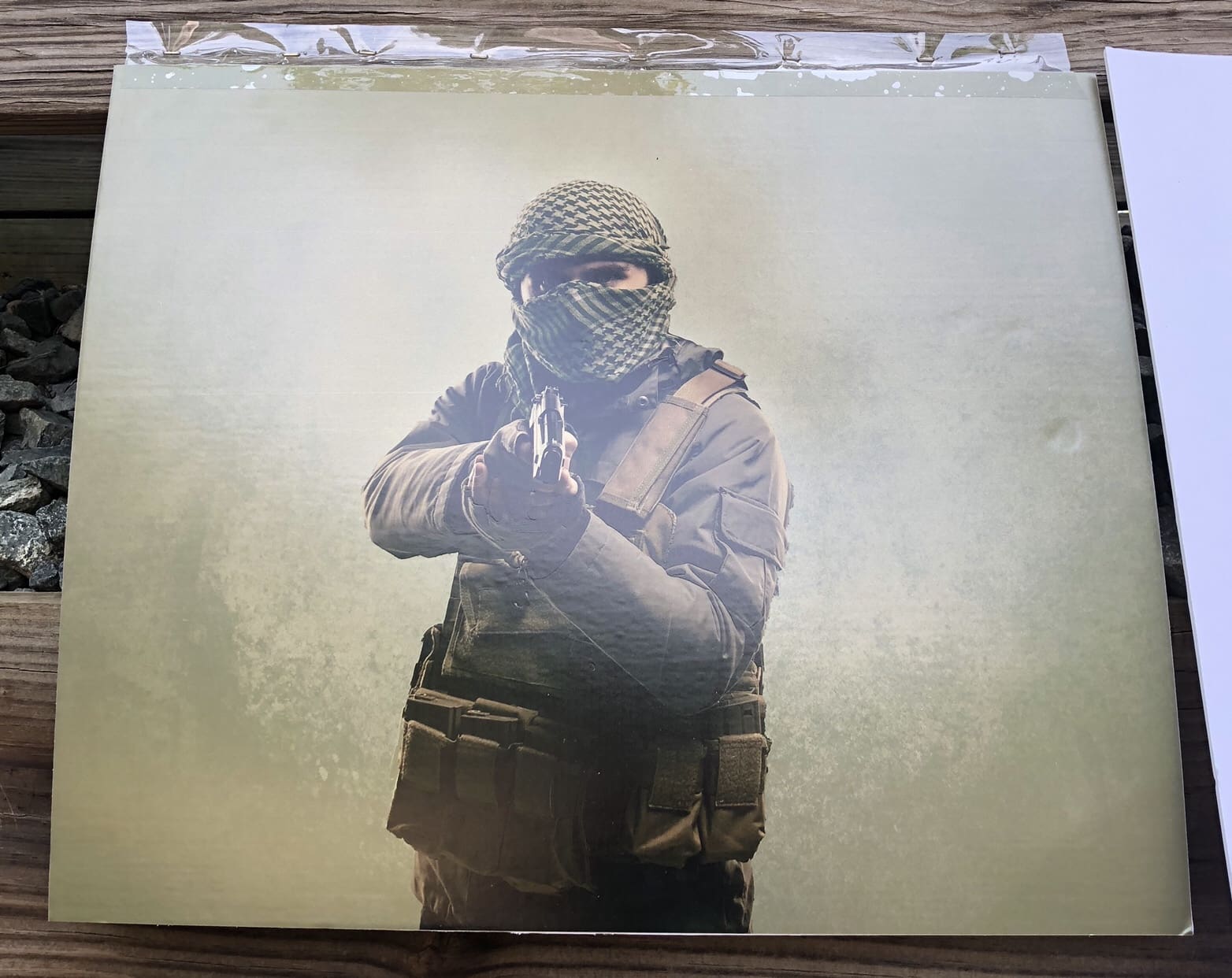

Hand held or helmet mounted, Senso-Optics’ X-SEE monoscope is based on proprietary Camera-on-Chip (ASIC) technology, with outstanding performance4 June 2018. Senso-Optics Ltd. is a hi-tech company, specializing in the fields of advanced electro-optic, thermal imaging and target acquisition systems for all-weather conditions and 24/7 vision solutions primarily for defense, HLS, search & rescue and other commercial markets.

The company will present its X-SEE FusIR, a hand-held or helmet-mounted miniature monoscope with VIS-FIR Fusion, at EUROSATORY 2018.

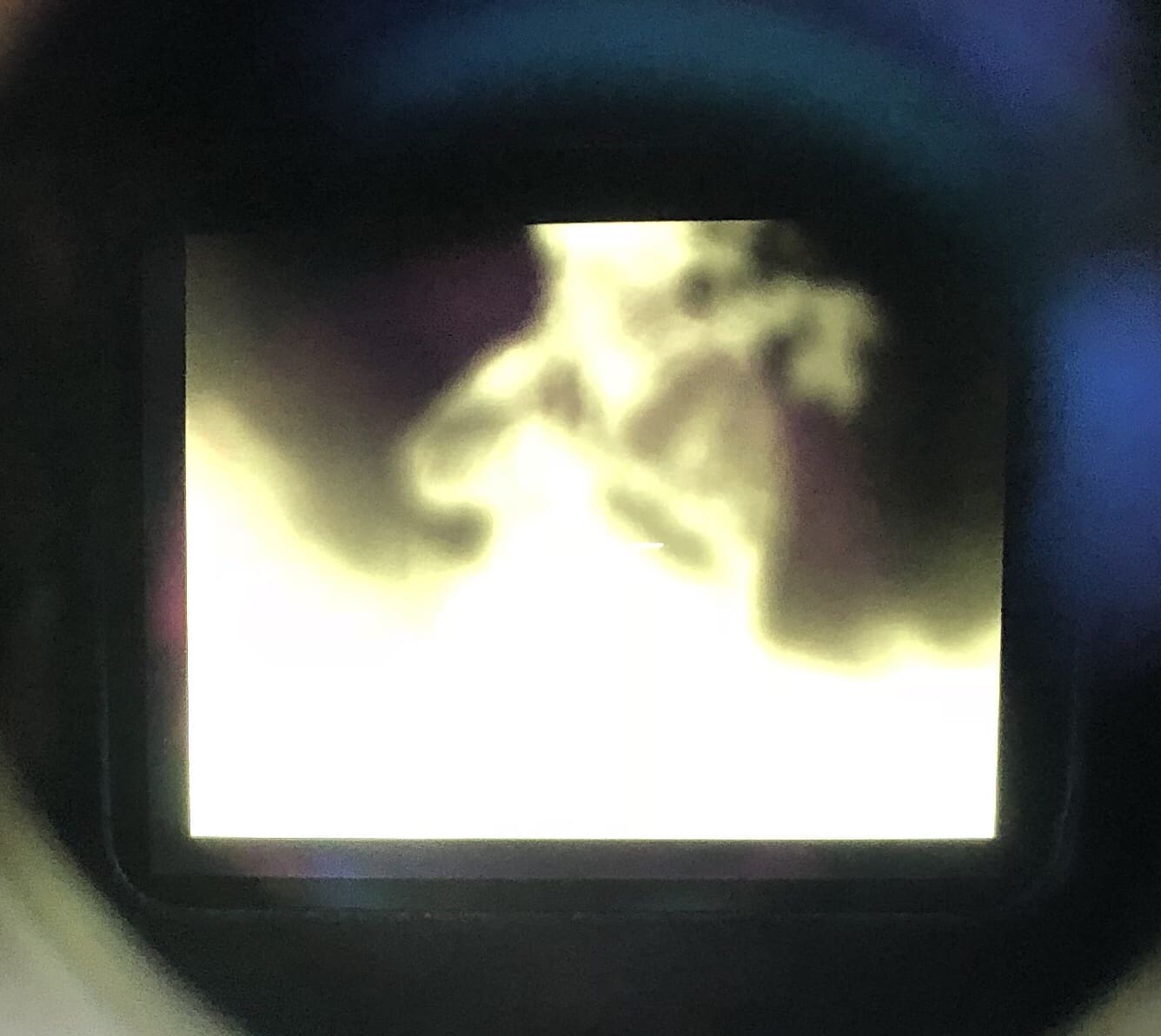

“We are extremely proud to present the new X-SEE FusIR monoscope, which uses the most advanced technologies to offer outstanding image fusion performance in miniature monoscopes,” says Jacob Dagan, President & CEO of Senso-Optics. “The new X-SEE FusIR monoscope is based on our proprietary Camera-on-Chip (ASIC) image processor, which generates exceptional image quality with VGA resolution (640×480) within tiny dimensions, weight & power consumption (SWaP). It offers the advantages of both VIS & FIR spectrum channels, day and night and in all-weather and environmental conditions (fog, dust, smoke, haze etc.). With X-SEE FusIR’s blended fused image, users can now see through glass windows, lights, signs and even colors, which they cannot do with thermal imaging alone.”

The X-SEE monoscope weighs only 300g with X1 lens, 400g with X2 lens and 700g with X4 lens, to suit a range of user requirements. It features several fusion modalities, including FIR (thermal-imaging) only, VIS (visual) only, controllable FIR-VIS blending, light source marking, X2 & X4 digital zoom and other features, which can be provided according to the client’s preference.

X-SEE FusIR is fully compliant with military standards, such as MIL-STD-810 and others.

www.senso-optics.com