British troops will soon be more lethal on the battlefield, as a new £90 million contract delivers modern, high precision rifles.

From:

Ministry of Defence and James Cartlidge MP

Published

7 September 2023

The new advanced rifle.

• New rifle provides UK troops with an improved lethal capability on the battlefield.

• Rifle more discreet through sight and hearing signature reduction.

• Up to 10,000 weapons could be procured over the next 10 years.

British troops will soon be more lethal on the battlefield, as a new £90 million contract delivers modern, high precision rifles.

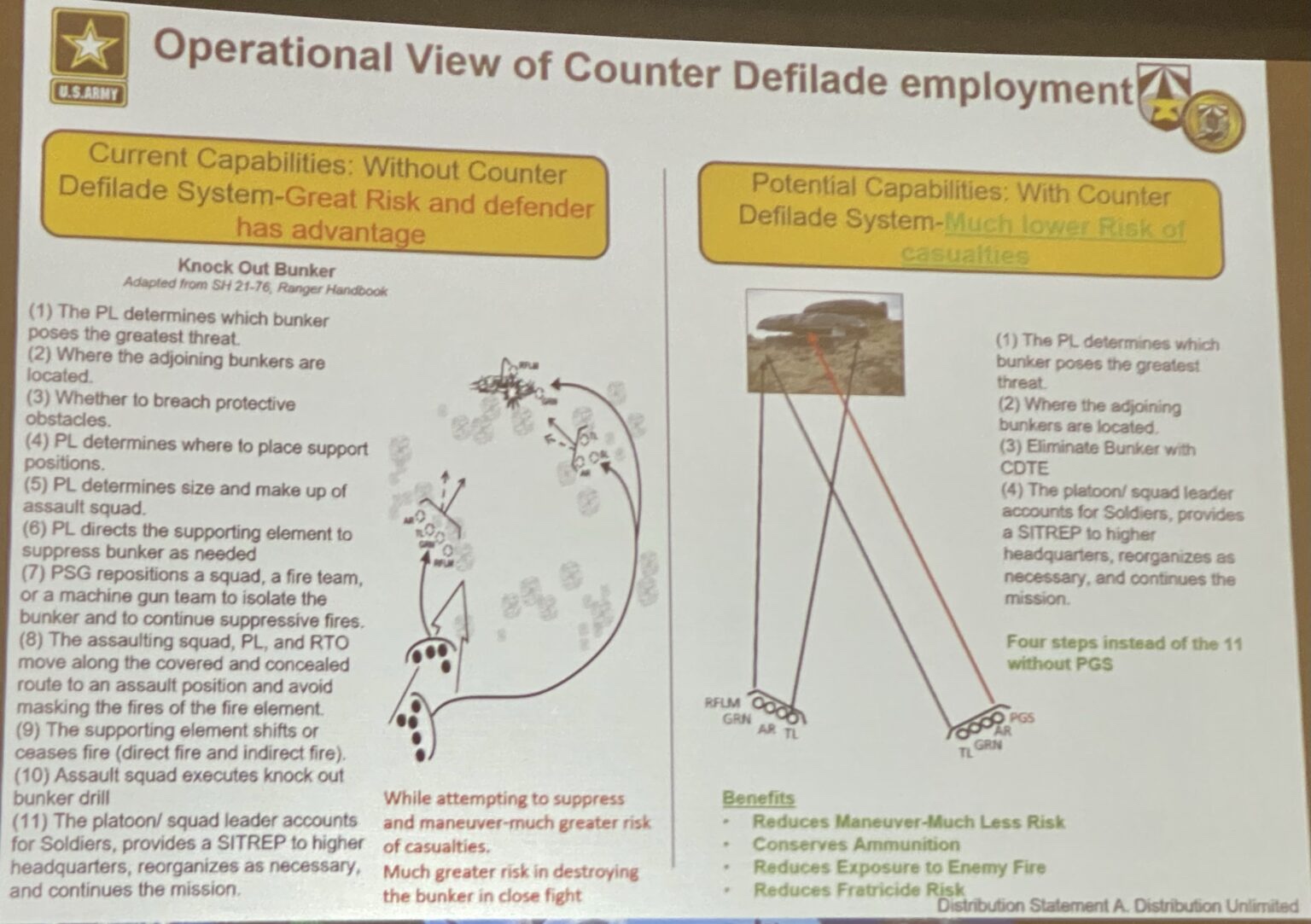

The Alternative Individual Weapon (AIW) system – known as the L403A1 and procured by Defence Equipment & Support (DE&S) under Project HUNTER – is made up of a new assault rifle fitted with a muzzle signature reduction system and an improved optical sighting system.

The AIW is a modern rifle using the latest in design technology and manufacturing methods, to produce an exceptionally reliable and accurate weapon. The magnified optic means the user is able to engage threats from greater distances; whilst the signature reduction system works to mask the AIW from detection from sight and hearing.

Supplementing the current in-service L85A3, the AIW system has been secured under a £90 million contract with Macclesfield-based company Edgar Brothers, supporting the Prime Minister’s priority to grow the economy by helping sustain approximately 50 jobs at the family-owned company.

Minister for Defence Procurement, James Cartlidge said:

This is another example of how we are committed to investing in the most advanced battlefield equipment to back our troops on the battlefield. This advanced rifle’s ability to help soldiers maintain the stealth edge not only protects them but delivers war-fighting advantage over our adversaries.

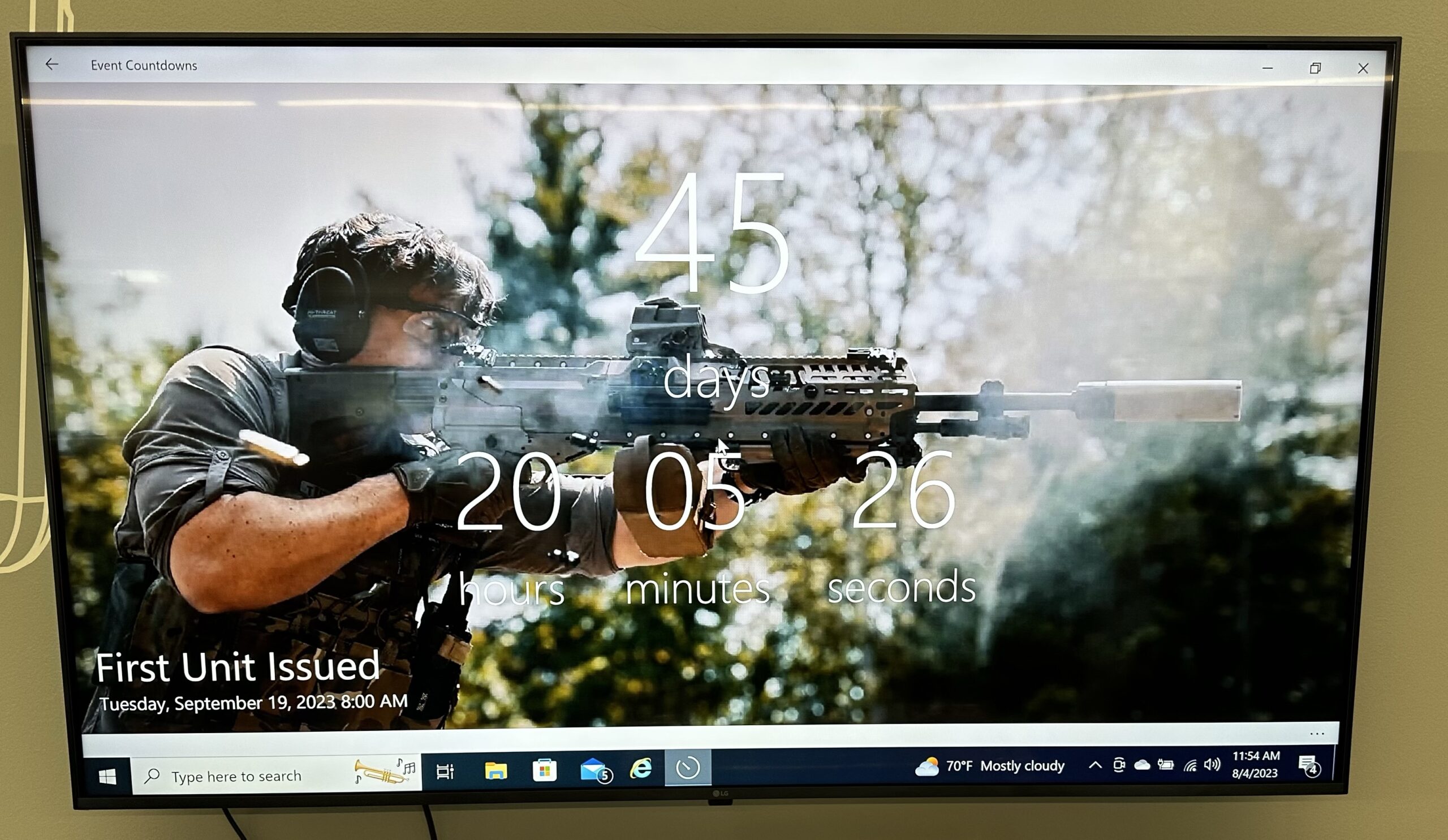

An initial £15 million order of 1,620 AIW systems has been placed, with options to procure up to 10,000 systems – totalling £90 million – under the contract over the next decade. The systems will initially be fielded to the Army Special Operations Brigade (ASOB) who operate in complex, high threat environments.

DE&S Dismounted Close Combat Portfolio Leader, Colonel Paul Cummings, said:

Project Hunter has been a fabulous example of close collaboration with the user community and strong engagement with industry to deliver game-changing capability at pace. This is another example of the enormous commitment of the men and women in DCC to deliver battle-winning capability into the hands of the user and I’m enormously proud of what they have achieved. We look forward to continuing to work closely with Edgar Brothers as we move into the production phase.

The L403A1 is a high performing modern development of the ArmaLite Rifle (AR), which pushes the boundaries of modern performance. As an AR system, it shares much in common with the rifle systems used by many of the UK’s allies. Given their specialist role, and the critical task of working with and alongside many of the UK’s allies, the platform will enable ASOB to share skills and drills in an efficient manner.

Lt Col Gareth Davies, SO1 SoldierWorks, Military Capability Delivery, Army Headquarters, said:

Project HUNTER has successfully delivered a new weapon option for UK Defence. At the current time this is being procured for the Army Special Operations Brigade (ASOB). It offers a marked increase in lethality, and the system includes one of most capable day sights currently available. Importantly the weapon system will be further enhanced by our newest generation of night optics, with which the ASOB are already equipped.

As a key component of the ASOB, the Ranger Regiment will receive the AIW later this year. Made up of four battalions, the Rangers deployed to over 60 countries in their first 12 months of operation, following their formation as part Future Soldier under the Defence Command Paper 2021.