Last week SIG SAUER delivered the latest tranche of weapons and ammunition to the US Army for the Production Qualification Tests (PQT) phase of the Next Generation Squad Weapons program.

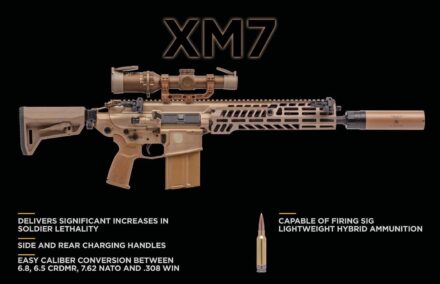

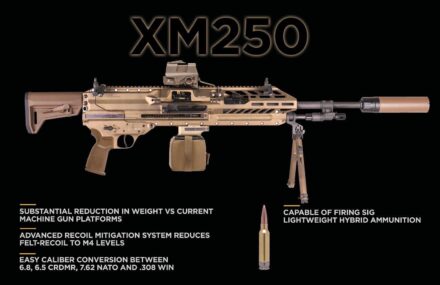

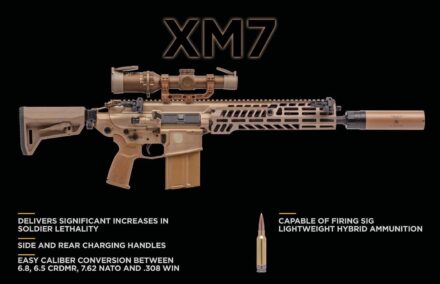

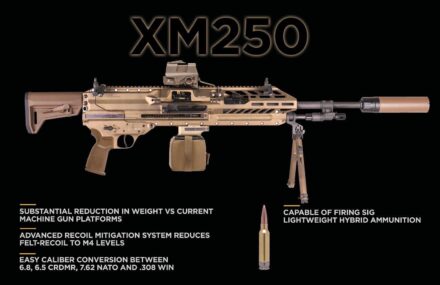

NGSW replaces the M4 carbine and M249 Squad Automatic Weapon which fire the 5.56mm NATO round with the XM7 Rifle and XM250 Automatic Rifle chambered in the new 6.8x51mm Common Cartridge Architecture Ammunition within the Army’s Close Combat Forces which are comprised of Infantry, Cavalry Scouts, and Engineers. All told, the program will be around 100,000 rifles and 30,000 automatic rifles.

This delivery of 34 x XM7, 44 x XM250, and around 300,000 rounds of 6.8×51 Common Case Architecture ammunition loaded as General Purpose (GP), Reduced Range (RRA), and Blank cartridges will be parceled out to several Army facilities to conduct simultaneous testing of various attributes.

According to the Defense Acquisition University, the PQT is a “technical test completed prior to the Full-Rate Production (FRP) decision to ensure the effectiveness of the manufacturing process, equipment, and procedures. This testing also provides data for the independent evaluation required for materiel release so the evaluator can address the materiel’s adequacy with respect to the stated requirements.”

The contract award was announced just a year ago, with SIG’s high pressure composite case cartridge design being selected over the True Velocity polymer case and Lone Star Future Weapons bullpup weapon combination. However, the journey to this point actually began in 2017 when then Chief of Staff of the Army, GEN Milley informed Congress that the service needed an Interim Combat Service Rifle in 7.62mm NATO to deal with overmatch issues on the modern battlefield.

The ICSR concept was quickly cancelled and would lead to a Prototype Opportunity Notice for the Next Generation Squad Automatic Rifle to replace the M249 SAW, which cast a wide net to industry to ultimately inform the Next Generation Squad Weapon requirement. Beginning in early 2019, NGSW challenged industry to develop a carbine, automatic rifle, and ammunition to deliver a government provided projectile at velocities mirroring the commercial 270 Win Short Mag cartridge. It was quite a tall order considering the limits on size and weight imposed by the Army.

The Army soon thinned the herd of close to 20 potential solutions to just three:

-AAI Corporation Textron Systems with their Case Telescoping ammunition

-General Dynamics-OTS Inc (later novated to Lone Star Future Weapons) with their polymer case ammo

-SIG SAUER with their composite case ammo

During the Other Transaction Authority procurement, the three vendors participated in numerous Soldier Touch Points, modifying their systems along the way and delivering improved designs at each phase of the program. Eventually, the Textron system was dropped from the program. At that point the Army faced a choice between a high pressure ammunition paired with a traditional firearm design from SIG and Lone Star Future Weapons’ bullpup weapons firing True Velocity’s polymer case ammunition. Ultimately, the Army selected SIG and since the award, they’ve already delivered weapons and ammunition for testing purposes.

Barring any unforeseen issues, fielding of systems in this fast paced program is expected to begin in the fall with SIG anticipating deliveries to the Army beginning in September. First Unit Equipped could be as soon as October.

In fact, SIG has been leaning forward in the foxhole throughout the entire process, investing in new infrastructure and manufacturing weapons components and ammunition in anticipation of each upcoming phase to avoid any delays. SIG has already reconfigured their production floor to accommodate the new manufacturing line. They’ve also been testing everything, from raw materials to full systems.

“We learned a lot during the Modular Handgun System program and have applied those lessons to how we approach NGSW”, said SIG SAUER CEO Ron Cohen. He went on stating, “This is the continuation of a long-term partnership with the Army to produce and deliver weapons, ammunition and target acquisition systems.”

With multiple contract wins over the past few years, SIG has developed a reputation of offering the government what they ask for, on time, and on price. For NGSW, they were also the only company to have both ammunition and weapon developed by the same company. While it was certainly an advantage during development, it makes things much easier now that they are moving toward full rate production. Any issue identified during testing can quickly be traced to its cause by assembling a team with representatives from across the company. What’s more, there’s not a back and forth over implementing solutions. While he makes the final decisions, Mr Cohen is results oriented and has empowered his team to get things done.

During our discussion Mr Cohen also pointed out an interesting observation. This is the first time in the history of the US military that they have simultaneously introduced a new caliber, rifle, and machine gun. This is sure to lead to unforeseen challenges across the DOTMLP-F spectrum.

Despite rumors to the contrary, and poorly researched and written articles, the NGSW program is not cancelled. To the contrary, it is moving fast, at the speed of war, with the first unit equipped this fall. From actual requirement to contract award was just over three years. From contract award to PQT is right at one year and that includes several months of no work due to contract protests. Considering the wholesale change involved, that is fast.

NGSW is happening. The next questions we will address are concerned with how this capability will transform the Army and whether the Army will expand this capability to those outside of the Close Combat Forces. Likewise, we also be watching to see if the other US services adopt NGSW as well as our allies and if so, how it affects them.