The American Southwest is a region that blends a harsh landscape, temperature extremes and various other non-environmental threats that can create dangerous obstacles for those who patrol the border. The territory is vast and monitoring it is critical to our nation’s security. That’s why the Science and Technology Directorate (S&T) is offering U.S. Customs and Border Protection (CBP) a helping hand (or “paw”) with new technology that can assist with enhancing the capabilities of CBP personnel, while simultaneously increasing their safety downrange.

S&T has a deep understanding of CBP’s technology needs in the field. In its role as the research and development arm of the Department of Homeland Security (DHS), S&T is always identifying solutions to support the complex CBP mission. For instance, S&T is currently supplementing CBP’s bipedal human personnel with quadruped mechanical reinforcements to help the agency better allocate resources. In this case, Man’s best friend comes with a very futuristic twist.

“The southern border can be an inhospitable place for man and beast, and that is exactly why a machine may excel there,” said S&T program manager, Brenda Long. “This S&T-led initiative focuses on Automated Ground Surveillance Vehicles, or what we call ‘AGSVs.’ Essentially, the AGSV program is all about…robot dogs.”

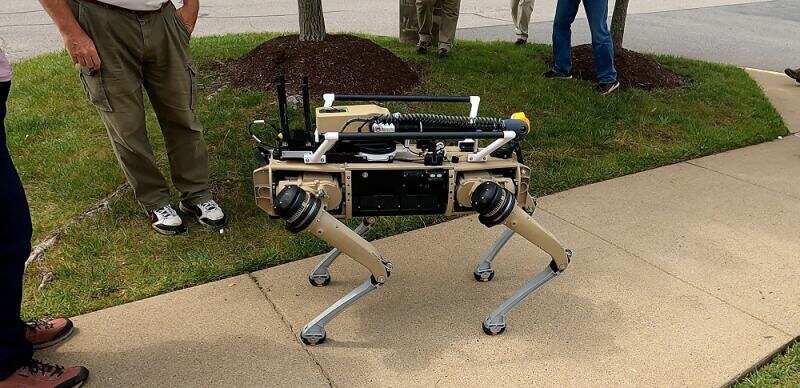

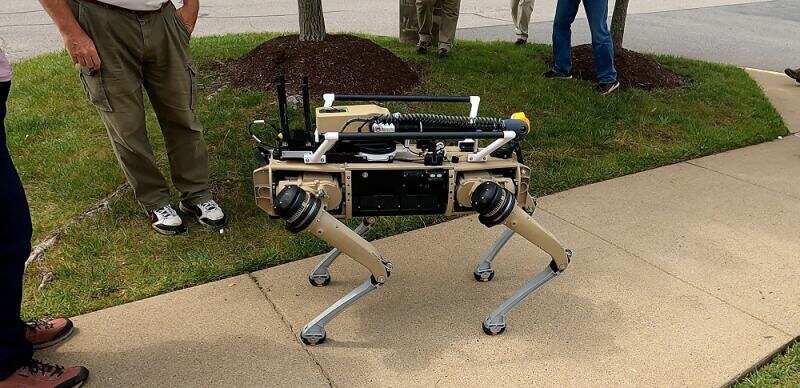

A robot dog showing off capabilities during testing in Lorton, Virginia.

The goal of the program is to leverage technology to force-multiply the CBP presence, as well as reduce human exposure to life-threatening hazards.

Early on, CBP voiced interest in a four-legged ground drone solution, and Long was more than happy to get to work on it. S&T’s AGSV Program collaborated with Ghost Robotics, an industry partner that develops advanced AGSV systems, to achieve the objective. When Ghost Robotics was brought into the fold, they saw an opportunity to re-engineer a version of their pre-existing robot dog for the multifaceted CBP mission.

According to Gavin Kenneally, the chief product officer at Ghost Robotics, their 100-pound robot dog was bred for exactly the type of work that CBP needs done, “It is a rugged, quadruped robot. It traverses all types of natural terrain including sand, rocks, and hills, as well as human-built environments, like stairs. That’s why you want legs, and not tracks.”

Downrange, the Danger to CBP Agents and Officers Is Very Real

Due to the demands of the region, adding quadruped mechanical reinforcements is a smart use of resources. Despite the dangers, and maybe even using them as cover, there are many types of illegal activity that happen in the harsh border zones.

“Just like anywhere else, you have your standard criminal behavior, but along the border you can also have human smuggling, drug smuggling, as well as smuggling of other contraband—including firearms or even potentially, WMD,” explained Agent Brett Becker of the CBP Innovation Team (INVNT). “These activities can be conducted by anyone from just a lone individual, all the way up to transnational criminal organizations, terrorists or hostile governments—and everything in between.”

A robot dog operating alongside ATVs in the southwest U.S. Photo: Courtesy Ghost Robotics.

Becker elaborated on the perils by adding, “Operating out in the desert or mountains, agents and officers have to contend with the rugged terrain, high heat and humidity, and then, of course, they can come across those who wish to do harm. But there are plenty of risks closer to home, too. For instance, when missions take Border Patrol Tactical Operators into towns, cities, or ports, they can encounter hazardous environmental conditions, volatile individuals, or hostile threats. These situations can all be inherently dangerous.”

The challenges that CBP faces are not lost on Long, “A big part of our job here at S&T is to understand the current operational needs of our DHS components and find innovative technologies to support them. We are keenly aware that the CBP mission is broad and the risks to personnel are many, and that’s why S&T’s work to fill capability gaps is so critical. And that’s specifically why we think that the robot dog solution is such a great fit.”

S&T Knows That Teamwork Makes the Machine Work

S&T has been working with CBP, Ghost Robotics, and the team for about two and a half years on specifications, development, and capability testing. This collaboration has yielded important CBP mission-focused advancements to the AGSV platform.

For S&T, building and managing partnerships (both interagency and public/private) is an integral part of executing its mission. S&T also understands that good communication is essential in any relationship, and that’s especially true when it comes to its valued partners.

“After talking with our partners at CBP INVNT, we built a team, and together, we identified the capability gaps, defined the challenges, and developed criteria and testing simulations called ‘use-case exercises.’ Then, having set the bar of expectation for the technology, we communicated all of that to our performer,” said Long.

A video camera or sensor package (known as a “payload”) can be attached to a robot dog. Photo: Courtesy Ghost Robotics.

Before moving into the use-case exercise phase, the robot dogs first went to a facility in Lorton, Virginia, for the “initial payload integration” phase. The so-called “payloads” are video and other sensor packages that, after being mounted onto the robot dog, can transmit real-time video and other data back to the human operating or monitoring the AGSV. The team assessed the ease and integration of loading different payload cameras, sensors, and radios onto the AGSVs, and then tested their ability to be controlled from a laptop or a handheld remote. Movement on asphalt, grass, and hills was also evaluated.

A robot dog practices climbing up and down grassy hills.

Having successfully passed the milestones in Lorton, things moved to El Paso, Texas, for advanced testing and evaluation.

S&T Capability Assessments Determine if the Programmable Pooches Are Up to the Task

A robot dog on maneuvers, traversing a rugged landscape in the desert southwest.Along the border, the challenges ramped up as the use-case exercises began. This phase assessed the capabilities of the robot dogs in realistic scenarios.

Long’s team worked with the U.S. Army’s Night Vision and Electronic Sensors Directorate (NVESD) and Ghost Robotics to ensure the robot dogs were prepared to engage in a diverse set of evaluation tasks. The El Paso use-case exercises would require the ability to maneuver in harsh environments, operate in tight spaces and be unphased by high heat, as well as low oxygen conditions—situations that are especially dangerous for CBP agents and officers.

“In a nutshell, the robot dogs would need to (figuratively) jump through a lot of hoops and show a significant amount of mission adaptability,” noted Long.

In an example of the platform’s desired flexibility, Ghost Robotics designed their payload capabilities as an open system. The benefit there is that it makes it easier to integrate different types of cameras (360-degree, thermal, night vision, zoom, etc.) and sensors (chemical, biological, radiological, nuclear, etc.) onto the robots. Once mounted, the payload is plugged into the high-performance CPU that runs the AGSV. During use, the AGSV maintains a connection to the operator via standard frequencies, such as radio, Wi-Fi, GPS, or other means.

To ensure that the AGSVs could deliver as promised, they were tested by walking up hills, down ravines, and over rocks, all while carrying 20-pounds worth of payload.

A robot dog scans a desert landscape with its camera and sensor while on sentry duty.Then, the testing transitioned to an indoor training facility that was built to replicate a residential building. There, the robot dogs would encounter a scenario that simulated being met by potentially hostile individuals. Set to the operator driven mode and using the wireless connection, the operator would maneuver the AGSVs to enter the structure, move through hallways, and peer around corners, as well as navigate stairs.

Later, in a desert area, the dogs were programed to go on simulated sentry duty. Under this autonomous mode setting, the AGSVs headed out and made turns when they reached pre-determined GPS waypoints. After completing their circuit, they returned to base. This was done in the daylight, as well as at night.

Additional testing included putting the dogs through the paces of simulated inspections outside, inside, and under train cars at railyards.

Endurance testing was also an important part of the overall exercises. Data was collected on battery life and impact of terrain on that endurance. Fortunately, when the Ghost Robotics team was working on its robot dog for CBP, the team focused a lot of energy on motor efficiency. Their objective was to ensure the battery-powered pooch could complete longer missions with the maximum payload onboard. They also designed their AGSV to be extremely nimble.

A robot dog inspects a railyard at night.Kenneally says that their robot dog’s legs are so advanced and sensitive that, “It has the ability to feel through its motors and can estimate friction forces and automatically correct for uneven or slippery ground.” This self-correcting ability makes it an ideal platform for off-road operations across multiple environments.

Some of the other mechanisms the team evaluated were basic field maintenance and repair, such as the ease of swapping out worn “paw” treads.

Valuable information was compiled from each of the exercises. Long explained the process, “When industry develops a prototype, we (along with our partners in the field) evaluate the new technology and give feedback to the developer. That way, the next iteration of the tech accomplishes what we need it to do—and thus fills the capability gap we are targeting.” The benefit to industry is that the performers can potentially position themselves to be even more useful to CBP in the future, when the prototypes become commercial products available for procurement.

S&T Is Committed to Addressing Capability Gaps

Overseeing programs to develop and test robot dogs in real-world scenarios is a great example of how S&T is dedicated to bringing the most innovative advancements to its DHS components.

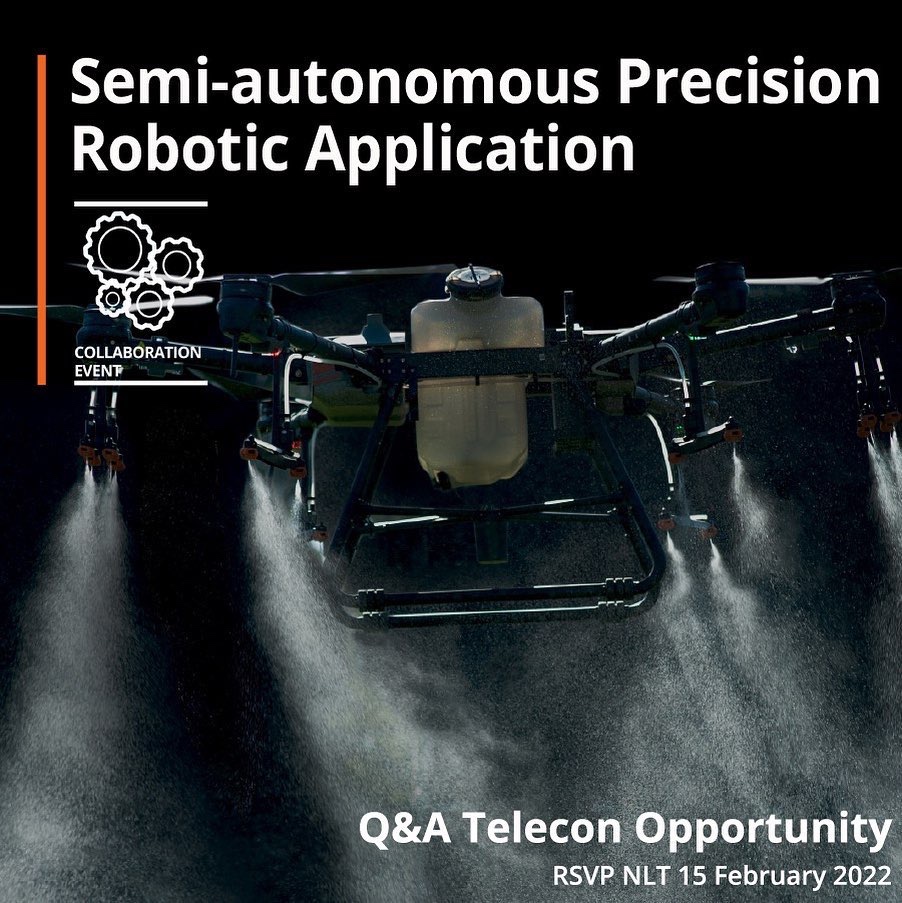

Long demystified the AGSV program by saying “Technology such as semi-autonomous drones (air, ground, and even water) are used effectively as force multipliers elsewhere—and robot dogs are no different.”

Robot dogs could fill important capability gaps and assist in the DHS mission. Photo: Courtesy Ghost Robotics.

In the future, could metallic beasts of burden shoulder some of the physically taxing and dangerous operational work to become a CBP agent or officer’s best friend?

After the successful completion of the use-case scenarios (that confirmed real-world capabilities) the robot dog work will continue with S&T leading the way. So, don’t be surprised if in the future we see robot “Fido” out in the field, walking side-by-side with CBP personnel.

Potentially a new best friend for CBP personnel in the field.