Typically, when you are diving, you want to stay as streamlined as possible. It will help keep you on time and help you use less air. But sometimes you have more things to carry so you might need to add more storage. The major problem with pockets on your thighs or hips is the drag it will create. When these pockets are full, they add about two to four inches to your profile. You can wear your BDU’s, and that will add pockets to your legs and arms. If you chose to wear a uniform, I would recommend the Patagonia Jungle uniform. It is super light and dries fast. You can also add pouches onto your gear belt, or you can put one or two onto your rebreather straps. An old school M16 pouch is great for a spare mask or extra fin straps. You can cut the grenade pouches off of the sides to reduce the drag. Here are a few after-market pockets options that can help you streamline your profile without sacrificing your gear needs or altering your existing gear in any way.

SCUBAPRO HYBRID CARGO SHORTS form-fit to your body like you were born wearing a pair. On the underside of the nylon panels, a micro-plush interior makes the shorts warm and cozy. This fleece fabric absorbs less water, which keeps heat against the body, increasing overall warmth. They also dry quickly. They can be worn by themselves, over a wetsuit, or if you need a little more warmth, they are great for over dive skins in warm water. They are also useful for items that need to be at the ready or if you need to tuck something away while diving.

The SCUBAPRO Hybrid Cargo Pants are made from 1mm X-Foam neoprene for warmth and durable nylon for stretch and comfort. They have an adjustable waist belt that includes an easy-to-use male/female squeeze buckle closure. Abrasion-resistant fabric on the seat panel provides additional protection. Highly versatile they are great for water jump, over the beach operations or combat swimmer where you don’t need a think wetsuit, but you want all the protection a wetsuit would provide.

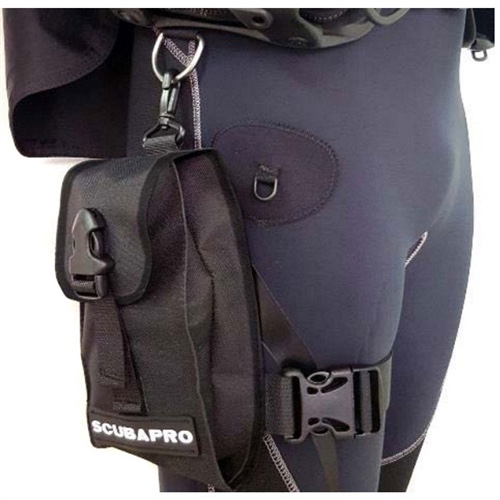

The SCUBAPRO Hydros Pro Cargo Thigh Pocket (full pocket with clips and straps) can provide the same storage as the Cargo shorts that capacity. Ideal for storing swimmer slates, lights, marker buoys, spare masks, compact cameras. Quick attachment via clips & thigh strap. The pocket has a large flap with a squeeze-style” side-release buckle closure. Bellow pocket design and large flap make access to stowed items easy and secure. The most significant feature is if you don’t need additional storage capacity, you can just remove the pocket for a more streamlined profile.

The SCUBAPRO Hydros Pro BCD Ninja Pocket is ideal for storing swimmer slates, lights, marker buoys, spare masks, compact cameras. Quick deploy when needed, roll-up when not. Pocket has a large flap with squeeze-style” side-release buckle closure. Bellow pocket design and large flap make access to stowed items easy and secure. All of the SCUBAPRO pockets are made from durable nylon fabric for strength and durability.

Another option is to glue pockets onto your wetsuit/ drysuit. This is way more permit, so make sure you get it right. You can do it yourself, but unless you have done things like this before, I would recommend having someone that has done it before showing you how to do it or have them do it. There are a lot of YouTube videos out there and articles about how to do this. There are pockets you can buy just for this purpose.

Click here to see a bunch of DIY instruction for gluing pockets to your suit.

SCUBAPRO Sunday is a weekly feature focusing on maritime equipment, operations and history.