WASHINGTON — Eleven top-performing Soldiers from around the Army came together Tuesday to receive the Army’s first-ever Expert Soldier Badges.

Army Chief of Staff Gen. James C. McConville made the presentation during the Eisenhower Luncheon at the Association of the U.S. Army’s Annual Meeting and Exposition.

“I’m really proud of what these Soldiers have accomplished,” Sgt. Maj. of the Army Michael A. Grinston said. “At the time, the [ESB] was a new challenge not only for them but for the Army. These 11 individuals can now proudly wear a badge that firmly recognizes them as experts in their profession, something all Soldiers should strive to be.”

Announced on the Army’s 244th birthday in June, the ESB is a proficiency badge designed to recognize a Soldier’s lethality outside of the infantry, by measuring their “mastery of physical fitness, marksmanship, and other critical Soldering skills necessary for combat readiness,” said Sgt. 1st Class Dennis Moore, the badge’s noncommissioned officer in charge at the Army Center for Initial Military Training.

“[The ESB] recognizes the next generation of competent, committed leaders who thrive in chaos, adapt, and win in a complex world,” said Master Sgt. Norbert Neumeyer, a U.S. Forces Command master gunner who oversaw the first ESB test.

In April 2017, 56 Soldiers were selected from FORSCOM units across the Army during the pilot phase of testing. Of those who tested, 12 passed, making the pass-fail rate on par with the Expert Infantryman Badge and Expert Field Medical Badge.

Spc. Mahrubius Ledford, released from active duty March 2019 , was unable to attend Tuesday’s ceremony.

For Staff Sgt. Tyler Lewis, a field artillery firefinder radar operator out of Fort Bliss, Texas, earning the ESB “represents all aspects of being a Soldier,” he said.

“Being a Soldier means being a tactical and technical expert from the level of basic Soldiering skills to the advanced levels of your [military occupational specialty],” he said. “A Soldier learns to be adaptable, disciplined, and master and steward of his or her profession in every situation.”

SHARPEN YOUR SOLDIERING SKILLS

For Sgt. Michael Ostrander, armament shop noncommissioned officer at Joint Base Lewis-McChord, Washington, he said he had to touch up his land navigation skills in order to earn his ESB.

The small arms repairmen said he relied on the Soldering skills he learned during basic combat training and throughout his military career during the test. He also suggested Soldiers planning to test for the badge “brush up on things they’re rusty on.”

For many Soldiers, the ESB tasks may seem like “common ones that have been taught before,” Lewis said. But, “[Soldiers] need to ensure that their knowledge is accurate to each standard tested. Practicing each skill until it becomes second nature is the key to success.”

Staff Sgt. Mike Mata, joint fire support specialist at Fort Sill, Oklahoma, echoed his fellow recipients when he credited “hands-on training and mock repetitions” to earning the ESB.

“It’s important to remember that testing is intended to be rigorous, mission-focused, and conducted under realistic conditions,” Neumeyer said.

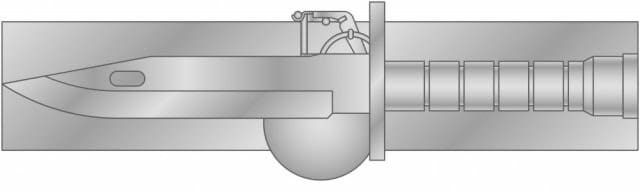

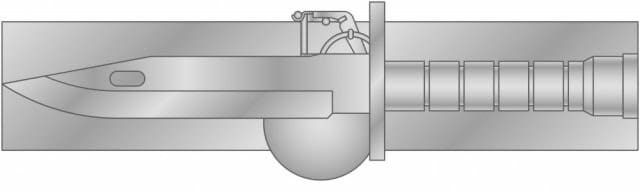

The new skill badge is an equivalent of the EIB and the EFMB. It’s nearly a spitting image of the Combat Action Badge, minus the wreath. The badge displays the same M9 bayonet knife and M67 frag grenade inlaid against a solid, gray rectangular bar.

The test includes various commander-selected tasks essential to their respective units, like how to respond to an improvised explosive device attack, forging fighting positions, finding Soldiers in a tactical environment, and how to mark chemical, biological, radiological, and nuclear-contaminated areas. Other tasks include a day and night land navigation test, a 12-mile ruck march, and a series of individual assessments.

The test also contains a variety of events, sharing roughly 80% of the tasks in the EIB and EFMB, and takes five days for Soldiers to complete. Standards for the test will not be adjusted based on age, gender, or any other criteria.

“The [ESB] will increase overall readiness and lethality, and the first recipients are among the top-qualified Soldiers in the Army,” Moore said.

To qualify, Soldiers must first pass the new Army Combat Fitness Test, slated to be the official fitness test for the Army by October 2020. Soldiers must also qualify as expert on the M16 or M4 and be recommended by their chain of command.

“The ESB gives units a baseline and ability to measure their Soldiers’ physical fitness,” Neumeyer said. “It also ensures Soldiers perform to standard all the critical tasks they’re supposed to have knowledge of, and measures their abilities to an expert level.”

Grinston said today’s awards are only the beginning for the Expert Soldier Badge, adding it will increase readiness and Soldier lethality across the force.

“We have ESB testing that will be underway later this month at Joint Base Lewis-McChord and next month at Fort Eustis,” Grinston said. “I look forward to seeing the results. This is a truly challenging badge to earn with training along the way that will help better prepare our Soldiers for combat.”

The first-ever recipients of the ESB include:

Staff Sgt. Joseph Alcorn, Joint Base Lewis-McChord, Washington

Staff Sgt. Freeman Harris, U.S. Army Garrison Stuttgart, Germany

Sgt. 1st Class Christopher Harvey, Joint Base Lewis-McChord, Washington

Staff Sgt. Thomas Jacobsen, U.S. Army Recruiting Office, Gretna, Louisiana

Staff Sgt. Tyler Lewis, Fort Bliss, Texas

Staff Sgt. Anthony Lodiong, Fort Bliss, Texas

Staff Sgt. Julio Macias, Fort Campbell, Kentucky

Staff Sgt. Mike Mata, Fort Sill, Oklahoma

Staff Sgt. Evan Neilson, Fort Jackson, South Carolina

Sgt. Michael Ostrander, Joint Base Lewis-McChord, Washington

Staff Sgt. Bradley Sherman, Fort Benning, Georgia

Spc. Mahrubius Ledford, released from active duty March 2019

By Thomas Brading, Army News Service