Bringing nothing to a gunfight

How much thought have you given to carrying personal protection tools other than a firearm? With the rampant increase in “gun free” zones are you still able to effectively and quickly protect yourself and loved ones.

Be prepared

Often times we get wrapped around the axle whether we can or cannot carry a gun. The subject of gun free zones is not relevant to this article, at some point we will all be in what I prefer to reference as “victim rich zones” or VRZ. The real question is what do you have available and have you trained for this contingency. I think it is foolish avoiding this subject, it is inevitable not to mention the consequences for breaking the law can be far more severe. While I recognize it is a personal choice, make sure you have weighed the options as well as consequences.

Think outside the box

In our Concealed Carry classes we talk about a threat matrix. This matrix is a breakdown of your perceived threat level as well as various loadouts. I ask all students to think long and hard into how you would effectively manage each of the blocks reminding them some blocks may not have any weapons at all. This exercise is incredibly helpful at addressing what to do when you must navigate a VRZ. The difficult part of many is recognizing the firearm free blocks. It sometimes is helpful to provide scenarios to this firearm free blocks such as going to the pool, boarding an airplane or visiting your children’s school. Even if you are permitted to carry in these locations now, recognize at some point you might not and better to acknowledge that notion now rather than later.

Create time and space

I find a firearm in the right hands to be incredibly effective at dealing with lethal threats. That should come as no surprise, but why is it effective? A major reason is it has the capability to launch multiple ballistic projectiles at varying distances. The key word is distances, in some cases you may not have access to your firearm even if it was permissible to carry so developing a layered defensive approach is sound. This approach can be scaled up or if necessary scaled down, but there is two more thoughts to consider here; metallic versus nonmetallic is one and whether you are subject to a physical search the other.

Plastic fantastic

Part of your threat matrix should include both metallic and nonmetallic weapons. If you cannot carry a firearm then you scale down to your next best options such as edged weapons, impact weapons, maybe chemical deterrents, stun guns and tasers should be considered. If you must navigate these VRZ’s frequently then suitable replacements must be explored and practiced with the same frequency as your firearms training. If you have to navigate these locations infrequently then scaling down is the better idea. On the nonmetallic side you may want to consider high impact plastic replacements for your normal array of edged and impact weapons. While these may lack some effectiveness as their metallic kin they will more than likely be adequate when you need them and can easily be replaced.

The black ops feel

If you must subject yourself to a physical search then stop and ask yourself is it really worth it for the simple reason your options are severely limited. However, there are still plenty to consider along with their covert method of carry and deployment. To me this is one of the most overlooked subjects within the concealed carry field. Carrying with no residual presence of any weapons. These types of options are available, but at a cost. Aside from the potential legal consequences the deeper the concealment the more difficult it will be to access; which puts even more emphasis on training.

Clothing attire, weapon selection and immediate actions to buy you time and distance to deploy your deep concealment options are becoming more and more relevant in our urban setting. This is were the art form of concealing really gets interesting.

– Jeff Gonzales

Trident Concepts, LLC

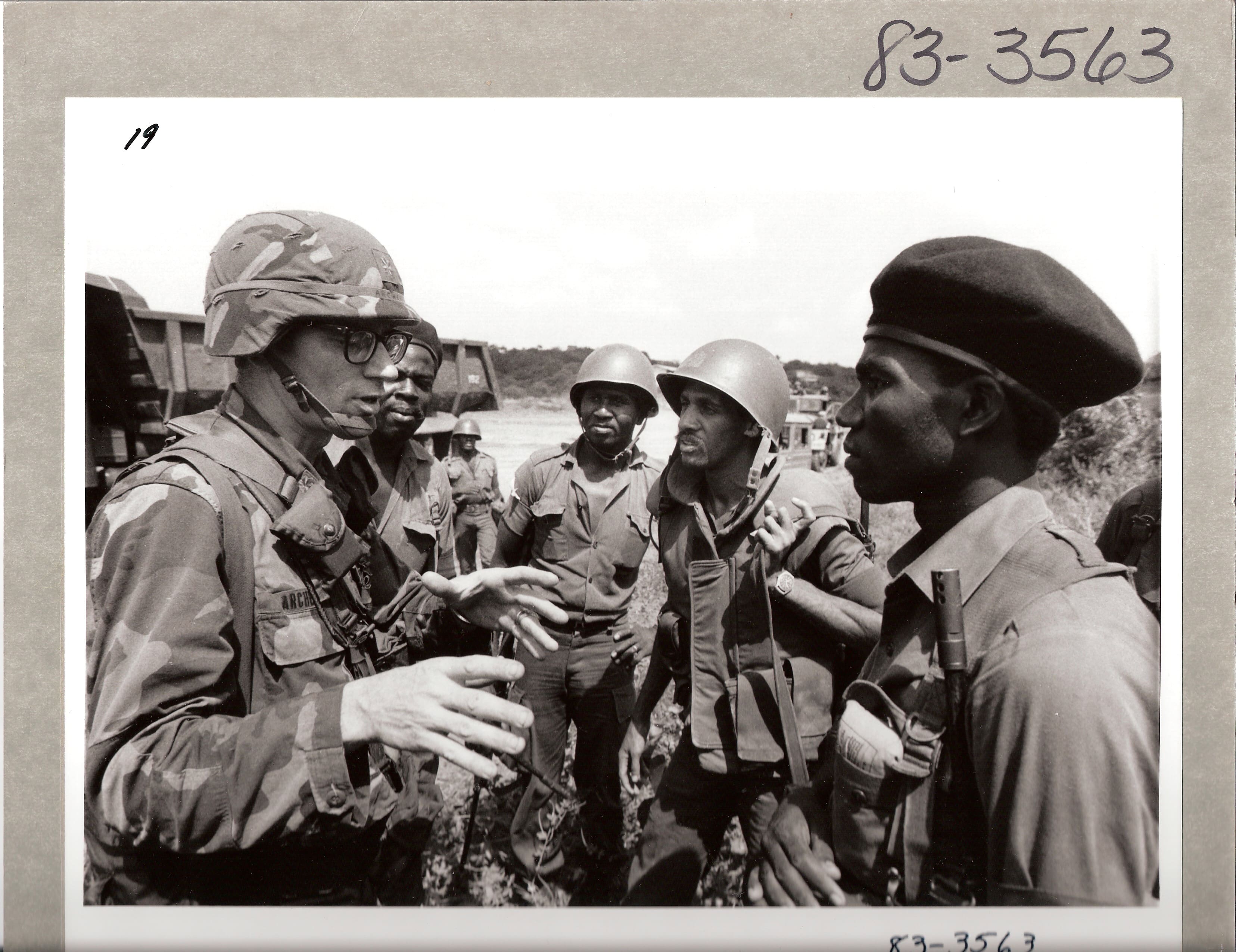

Jeff Gonzales of Trident Concepts, LLC is a decorated and respected U.S. Navy SEAL who has worked in a variety of environments and capacities throughout the globe. He specializes in personal protection tactics and training for armed and unarmed conflicts. His motto is “Concepts that meet reality”. Jeff’s goal is not simply to train you, but to better prepare you for the worst-case scenario.

Gunfighter Moment is a weekly feature brought to you by Alias Training & Security Services. Each week Alias brings us a different Trainer and in turn, they offer some words of wisdom.