It doesn’t matter who builds your ammo backpack system, the issue is the feed chute, both from a cost and to a certain degree! weight standpoint. Generally, the more money you spend on a feed chute, the more it’s going to cost. Until now.

Down East, the guys who developed the all but indestructible MOLLE frame as well as the FastMag family of products put their knowledge of plastics to work on developing a new 7.62 feed chute and came up with this solution. The idea is to bring the price point down to make wide spread fielding affordable rather than niche products.

According to Down East, “The internal geometries and materials are designed to allow the ammo to feed more freely, while gaining some range of motion. The design is also easily scalable to 5.56, 30mm, etc. once we have worked the kinks out. Instead of rehashing the WW2 era metal version over overlapping plates, we are going with a patent pending modular design which could be used on a pack, for a fixed emplacement (as in a FOB), or on a vehicle.”

This is a first look at their first generation production item that they have just begun wear testing. By design, the chute feeds in either direction and is constructed of interlocking links, allowing it to be repaired or resized. You can cut out an even number of links, or cut one section of connectors and add an even number of links. What is really cool is that the links are made from their proprietary fragmentation resistant polymer (used in the MOLLE and FILBE pack frames) and is available color matched and NIR compliant with the major camouflage patterns (Coyote 498, TAN499, FG 504).

In the photos they have a mesh cover over part of the chute and this is an attempt to reduce the reflectance of the brass without totally enclosing the chute. However, this isn’t required and they could just as well leave the chute completely uncovered or offer a a full fabric enclosure. The end of the chute features a standard type attachment for the M240B. The pack pictured here uses the same sort of bracket to mount the other end of the chute.

The feed cute pictured is 44” compressed and 56” fully extended, and weighs approximately 3.5 lbs. Depending on testing they may be able to further lighten the load.

It’s very important that you understand that this feed chute is for a ground role only. This isn’t meant for aviation applications. It’s a plastic product after all. The big issue here is to determine how long these can stand up to the rigors of day-to-day carriage with ammo on them as well as while firing. I do know that Down East ran over one with a truck and it survived which is promising.

They are still working out cost, but, based on where they are they’re anticipating a fraction of the $1700-2200 that metal chutes currently run.

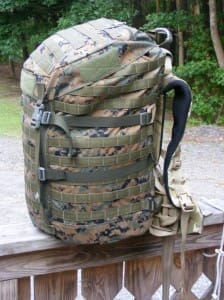

Look for details on a ver 2.0 soonish as well as some additional info on the pack in the photos which utilizes the 1609 frame developed for the US Army medium ruck.

www.downeastinc.com