Point Blank Enterprises uses DSM Dyneema material innovation to develop Generation II Soldier Plate Carrier System armor designed to maximize mobility and provide superior protection

Stanley, N.C., Dec. 16, 2014 – DSM Dyneema, the manufacturer of ultra-high molecular weight polyethylene (UHMwPE) fiber, branded as Dyneema, and a world leader in life protection materials and high performance fibers, announced today that the U.S. Army has chosen a new body armor system that incorporates Dyneema Force Multiplier Technology to deliver unparalleled ballistics protection combined with unprecedented weight reduction.

Point Blank Enterprises, the worldwide leader in the production of soft body armor, designed the advanced ballistics package incorporated in the new system – the Generation II Soldier Plate Carrier System (SPCS).

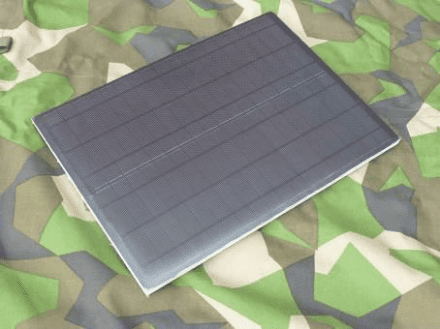

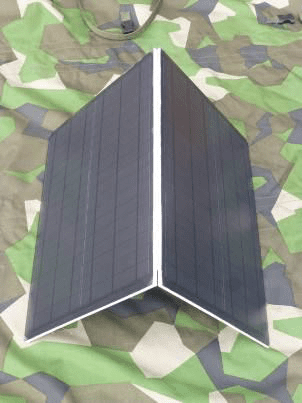

Using revolutionary Dyneema Force Multiplier Technology, Point Blank developed the core ballistics package for the SPCS to create the lightest soft armor system ever to be fielded to the U.S. Army. The lighter weight ballistics package meets the Army’s requirement for the SPCS to provide protection equal to the current Improved Outer Tactical Vest (IOTV), but in a standalone capacity that reduces the soldier’s load and provides optimum mobility.

“Dyneema Force Multiplier Technology helps armor manufacturers achieve the goal of combining the best protective performance with the lightest possible weight,” said Shitij Chabba, Global Segment Director, Life Protection, DSM Dyneema. “We are very pleased that our latest material innovation has achieved qualification for an advanced program like SPCS that must meet modern mission requirements.”

Built on the company’s Radical Innovation Platform and manufactured in Greenville, N.C., Dyneema Force Multiplier Technology combines breakthroughs in polymer science, next-generation UHMwPE fiber technology and unique uni-directional engineering. Compared to body armor made from traditional materials such as aramid, protective vests engineered with Dyneema Force Multiplier Technology can reduce weight by up to 30 percent, while enhancing comfort and agility with fewer layers of material.

“Current and near-term predicted threats dictate that service personnel exhibit greater flexibility than ever before and an ability to respond quickly and decisively to changing conditions,” said Sam White, Executive Vice President, Point Blank Enterprises. “The combination of our cutting-edge ballistics package design and DSM Dyneema’s breakthrough Dyneema® Force Multiplier Technology has resulted in an unmatched ability to accomplish the critical objectives of SPCS specifications, all while delivering the lightest and highest-performing protection. We’re honored to partner with DSM Dyneema to bring this game-changing system to our service men and women, and remain committed to protecting those who risk their lives every day to safeguard ours.”