CAMP PENDLETON, Calif.—On a rather secluded and undeveloped piece of southern California coastline lies a succession of nondescript buildings that seem unremarkable to the naked eye. Yet, inside these structures, sophisticated laboratories are housed with highly skilled engineers and technical experts testing the very limits of battlefield communications, and they need to train their replacements.

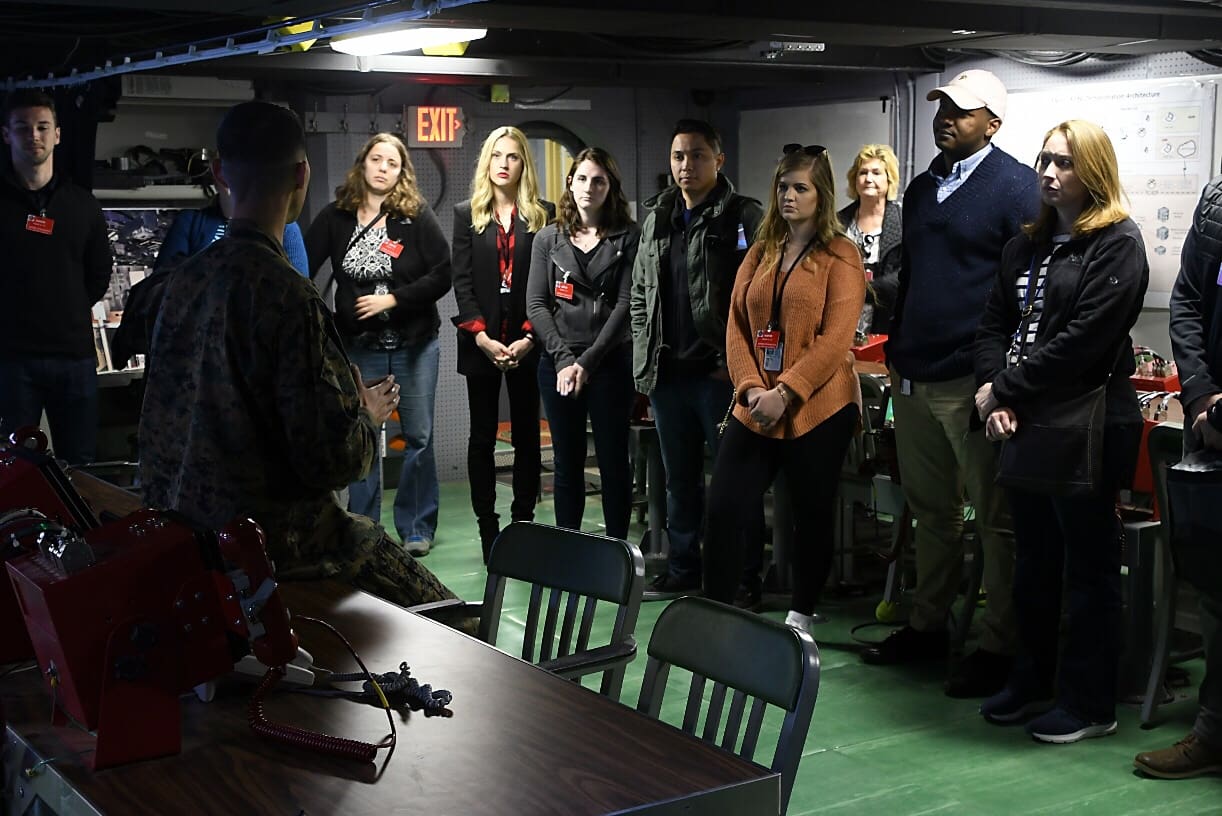

Building the future acquisition workforce is an important initiative within the Department of the Navy, which is why Marine Corps Tactical Systems Support Activity personnel provided technical demonstrations and briefings to approximately 80 Naval Acquisition Development Program entry-level employees from across the country Feb. 26, aboard Marine Corps Base Camp Pendleton.

Ric Gay (left), Marine Corps Tactical Systems Support Activity satellite communications laboratory engineer, recently discussed satellite communications and operations with Naval Acquisition Development Program entry-level employees during a tour of the command Feb. 26, aboard Marine Corps Base Camp Pendleton, California.

The NADP is a two- to three-year development program that recruits and trains future acquisition workforce members. New employees receive detailed training in contracting, finance, cost estimating, engineering, facilities engineering, IT, logistics, program management, and test and evaluation.

“NADP helps new employees in various career fields become future acquisition leaders for the Department of the Navy,” said Shelly Best, Naval Acquisition Career Center NADP career manager.

There are currently around 1,000 NADP participants across the continental United States, Hawaii and Guam.

“MCTSSA has been a beneficiary of this program for 15 years, and several of our co-workers are current or former NADP participants,” said David Yergensen, MCTSSA senior principal engineer.

During the most recent hiring season, NACC received 34,000 applicants. Among those, 15,000 were highly qualified for only 600 positions.

“It is our goal to introduce these new acquisition professionals to the Sailors and Marines at various activities and give them a chance to ‘see and touch’ some of the hardware used by the warfighter and acquired through their acquisition efforts,” said Ron Fevola, NACC career management division head.

Command customers heavily rely on NADP to assist with the replenishment and development of their future acquisition workforce members, said Fevola.

“Our goal is to hire the best of the best,” he said.

NADP is a great source for entry-level technical talent, said Yergensen.

“These are highly motivated and enthusiastic employees typically in their first professional position,” he said “Getting good employees into the government early increases the probability that they will stay with the government, even if they move on to other agencies.”

The one-day event at MCTSSA highlighted current technical objectives involved in supporting the command, control, computer and communications—or C4—systems used by expeditionary warfighters.

“I appreciate everyone’s patience and the knowledge they shared with not only me, but the whole NADP team,” said Christina Berenato, Naval Sea Systems Command NADP participant. “Exploring behind the scenes, and witnessing the hard work and dedication put into keeping our nation safe was extraordinary, truly a day I will never forget.”

U.S. Marine Corps Capt. Caleb Wu (left), Marine Corps Tactical Systems Support Activity naval systems integration officer, speaks to Naval Acquisition Development Program entry-level employees during a tour of the command’s Landing Force Operations Center laboratory environment Feb. 26, aboard Marine Corps Base Camp Pendleton, California.

Whether learning about combat operations centers, satellite communications, Networking On-the-Move, cybersecurity, networks, radars or amphibious vehicles, the participants saw a large breadth of systems and how they relate to warfighter support.

“MCTSSA is a great place to start a technical career in the Department of Defense,” said Yergensen. “We have a majority of the Marine Air-Ground Task Force C4 systems integrated into a realistic test environment.”

NADP employees at MCTSSA get to work with a variety of systems at multiple stages in the acquisition life cycle and perform hands-on experiments, trade studies, test and engineering assessments, installation, configuration and troubleshooting in a lab environment, said Yergensen.

“We also get them into field support to experience the operational environment firsthand,” he said. “Our NADP employees get to work closely with active-duty Marines, which helps them understand who and how the systems are used. This would be hard to find in any other C4 organization.”

Many of the NADP tour participants appreciated learning about the development of C4 equipment.

“It was interesting to see the advancement in technology benefitting COC operations and their forward-deployed elements as they maneuver through the battlespace,” said Jason Fraker, Naval Facilities Engineering Command NADP participant.

Berenato echoed similar sentiments.

“I learned about Networking On-the-Move,” she said. “It is reassuring to know the new technology no longer geographically tethers commanders to the COC.”

From viewing improvements in technology to getting a better understanding of the big picture as it relates to the acquisition workforce, participants walked away more prepared to support the warfighter.

“Any command could benefit from learning about both the research done at MCTSSA and the manner in which MCTSSA operates with precision,” said Brooke Didier, Naval Sea Systems Command NADP participant. “MCTSSA is a leading force for military research and development, and quite frankly, as an entity of the Marine Corps, MCTSSA runs like a well-oiled machine.”

Marine Corps Tactical Systems Support Activity hosted 80 Naval Acquisition Development Program entry-level-employees during a tour of the command Feb. 26, aboard Marine Corps Base Camp Pendleton, California.

Tucked away at this inconspicuous beachside facility, MCTSSA has over 40,000 square feet of engineering and lab spaces operated by Marines and technical experts with the sole purpose of making Marines more capable. The future acquisition workforce that bared witness was impressed.

“I appreciate all the hard work MCTSSA does to excel at their jobs and to showcase their spaces to the interns who will be assisting future missions,” said Yvette Tsui, Space and Naval Warfare Systems Command NADP participant. “Thank you.”

MCTSSA, an elite, full-scale laboratory facility operated by the Marine Corps, is a subordinate command of Marine Corps Systems Command. MCTSSA provides test and evaluation, engineering and deployed technical support for Marine Corps and joint service command, control, computer, communications and intelligence systems throughout all acquisition life-cycle phases.

By Sky M. Laron, Public Affairs Officer, MCTSSA