Redlands, California, August 25th, 2022—Over the years, TNVC has been fully committed to making the very best and very latest, MIL-SPEC, duty-ready night vision, thermal, and visual augmentation systems technology available to ALL customers, not just the privileged few. Continuing this trend, TNVC is extremely proud to announce the release of a brand-new product line: TNVC SuperGain Systems.

tnvc.com/supergain

The TNVC SuperGain family is based on the latest image intensifier tube technology from L3Harris, and is one of the most significant evolutions in Generation 3 night vision systems and performance since the introduction of Unfilmed technology and are available ONLY at TNVC as a new Premium Option for all TNVC customers.

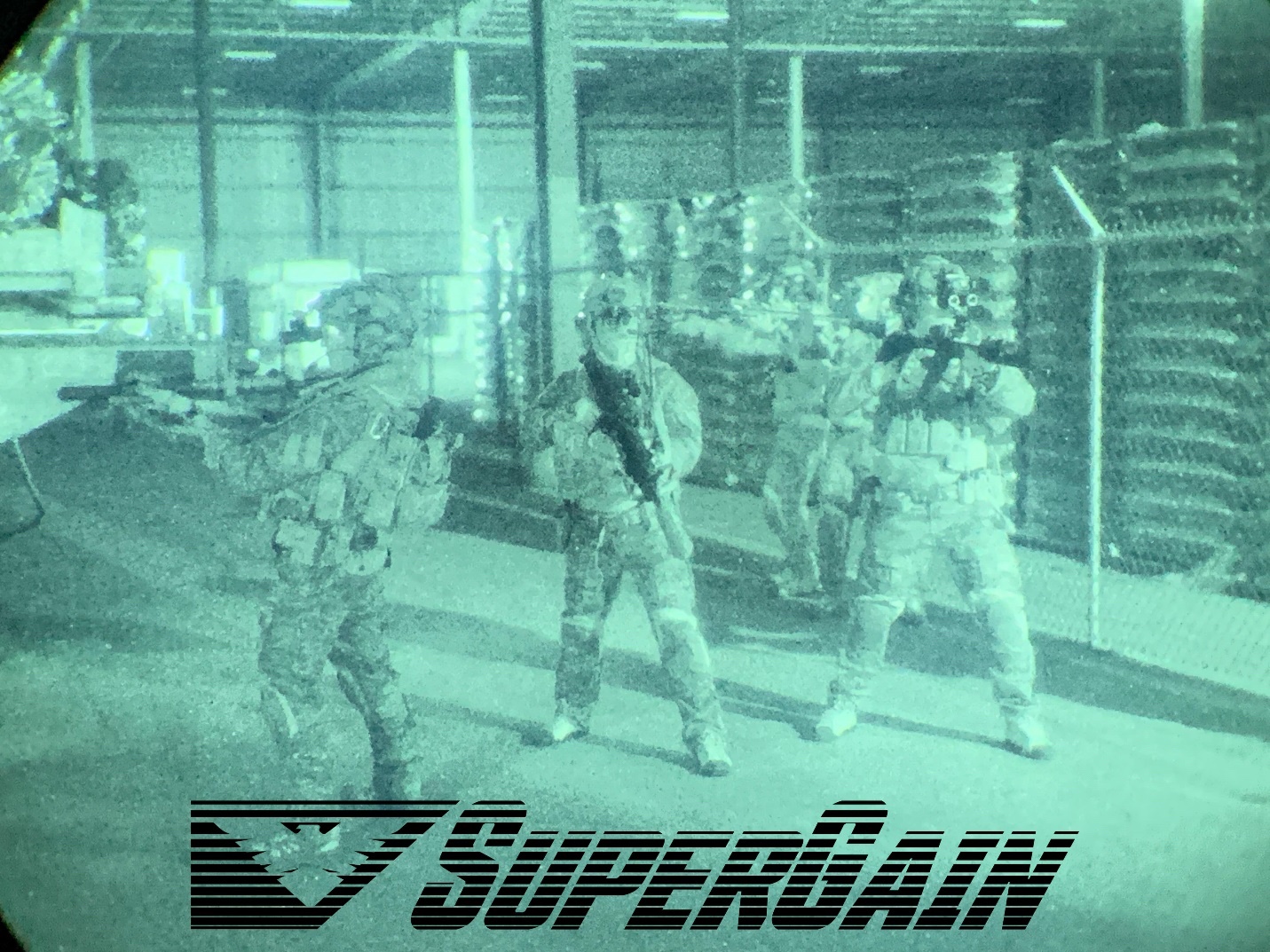

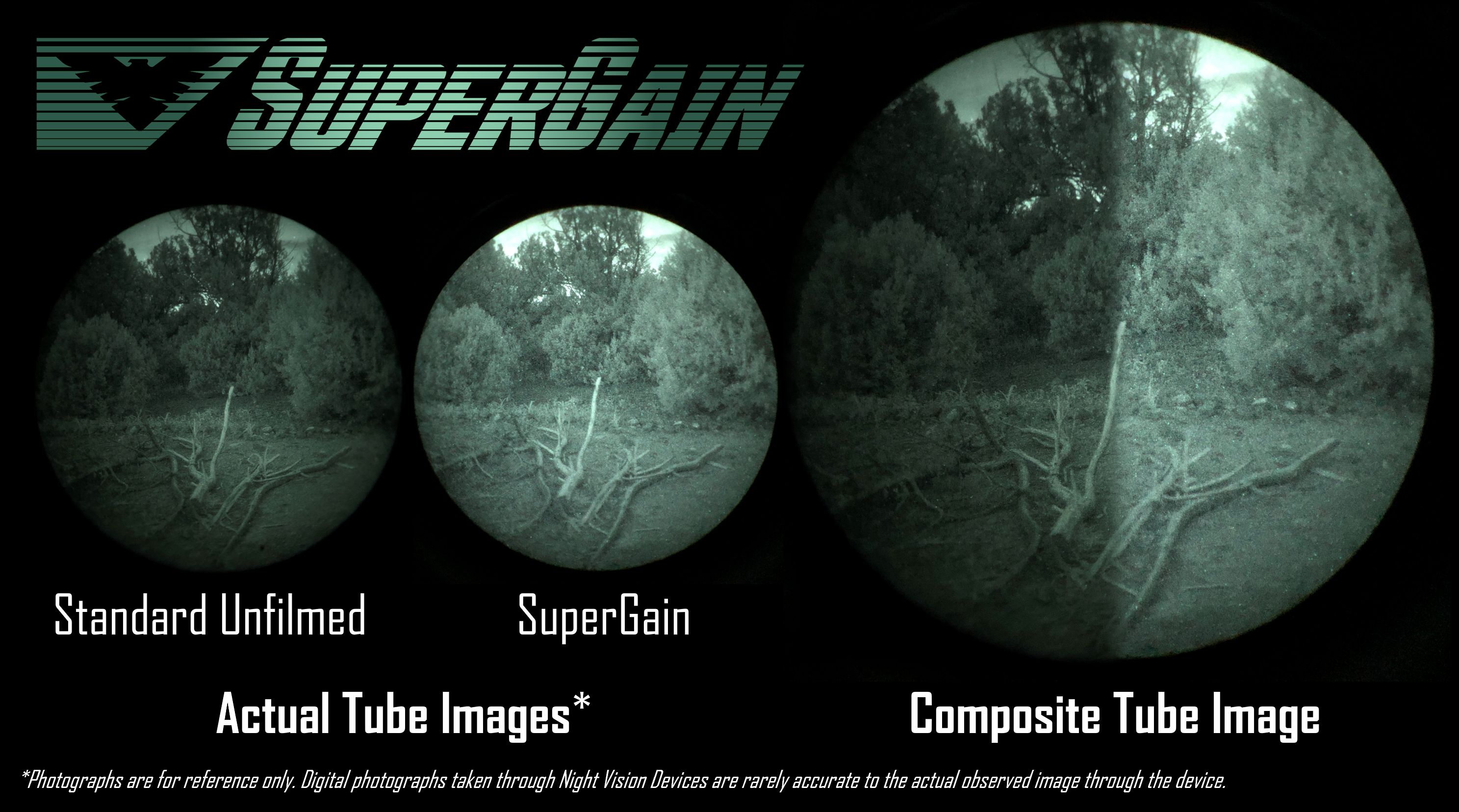

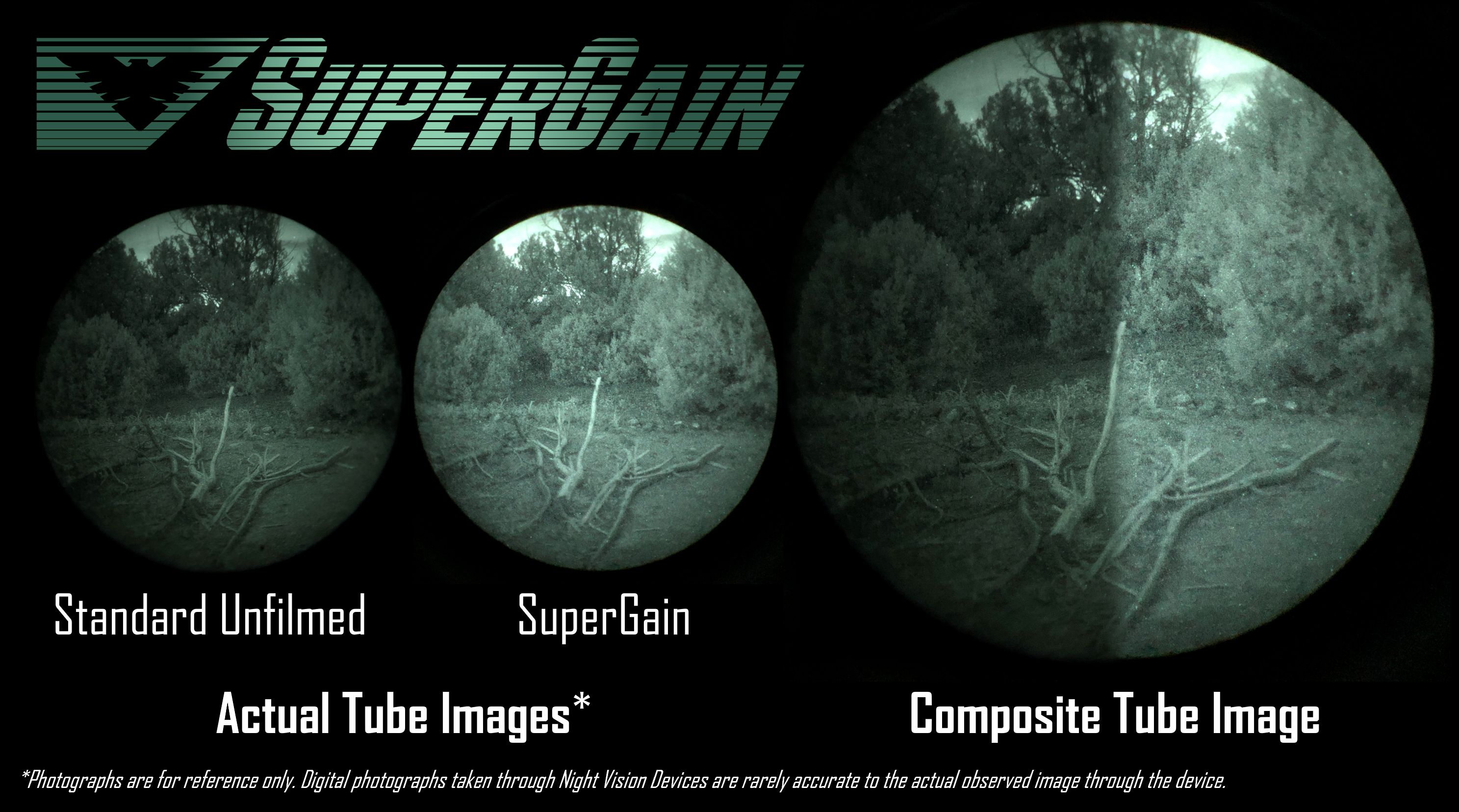

Already in use with the United States military, including Special Operations Forces, these new SuperGain Unfilmed White Phosphor image intensifier tubes increase the Luminance Gain (Gain) specification for image intensifier tubes from the standard 40,000-80,000 fL/fc to between 100,000-120,000 fL/fc, greatly increasing the image intensifier’s ability to amplify and collect light, providing increased low light performance and extending operational envelope when compared to night vision systems utilizing conventional Unfilmed White Phosphor image intensifiers.

These new MIL-SPEC SuperGain image intensifiers will be available in all TNV-branded night vision systems, including the TNV/BNVG-M Artemis, TNV/DTNVS, TNV/RNVG, and TNV/PVS-14 as well as L3Harris-manufactured BNVD (PVS-31) and BNVD-1531 systems, all with an increased 2376+ Minimum Figure of Merit (FOM) specification. These new units will exist alongside current TNVC offerings, including those with standard Unfilmed and Filmed image intensifier tubes.

***SuperGain tubes are currently IN-STOCK for all TNV-systems. L3Harris systems will be available for Pre-Order***

SuperGain image intensifier tubes have undergone extensive testing both by the U.S. Army at Fort Belvoir and USSOCOM and Special Operations Forces organizations, and are currently being fielded and in-service around the world in the newest, most technologically advanced night vision systems in the force, including the AN/PSQ-42 ENVG-B Advanced Goggle as well as panoramic fusion goggles.

“From the end-user’s perspective, the SuperGain tubes will be noticeably brighter than standard Unfilmed White Phosphor tubes under most conditions and will provide more useable information in extreme darkness. However, I think the most significant difference that users in the field will see is the ability to see deeper into dark corners and underbrush, allowing them to detect potential threats beyond the range of typical image intensifiers. This can be a significant advantage in both urban areas / inside of structures as well as in more rural areas with vegetation and heavy canopy and subterranean operations” said Augee Kim, COO of TNVC.

While many consumers, both government and commercial have been focused on FOM (Signal to Noise Ration multiplied by Center Resolution expressed in lp/mm) as a metric for image intensifier performance and image quality, with manufacturers pushing the envelope of performance through improved methods and processes, Luminance Gain is typically set by the manufacturer.

Because Gain has typically been set by the manufacturers and is relatively stable, its importance to image intensifier performance has often been lesser discussed when talking about image intensifier performance, however Gain is one of the most critically important factors of image intensifier performance, with the “failure” implied in MTTF (“Mean Time to Failure”) of an image intensifier representing a roughly 50% loss of Gain.

“In the past there has been a concern that too much gain could lead to increased and undesirable noise in the image, which can be true with lower performance tubes” said Kim, “however as tube performance has continued to improve, with less noise overall, increasing the gain can increase the amount of useful information provided to the user,” said Kim.

In order to maximize the benefits of the increased Gain, these new SuperGain tubes from TNVC will also feature a minimum Figure of Merit (FOM) specification of 2376, the highest minimum performance specification currently available to the wide market, and with actual average tube performance exceeding that of current USSOCOM specifications.

Not only do SuperGain tubes provide improved light amplification and more information to the user, but effects can be felt on the user’s end as well—the overall brighter image allows the pupil to remain smaller, even in low light conditions where image intensifier tubes begin to dim, effectively improving the user’s vision and allowing them to take full advantage of the information provided by the SuperGain tube as well as reduce eye fatigue from long term use. Meanwhile, neither image intensifier life, nor reliability are affected, with SuperGain tubes being every bit as durable and reliable as typical Unfilmed White Phosphor image intensifier tubes.

“It sometimes amazes me how much analog image intensifier performance keeps progressing,” stated Kim. “In a world where digital technology is rapidly overtaking analog systems, analog image intensifiers are still the very best technology available for night vision and visual augmentation systems. It’s shocking both how much *and* how little Generation 3 image intensifiers have changed since their introduction in the late-1980s.”

“On the one hand, the same basic technological architecture of the Gen. 3 tube and photocathode remains—on the other, the level of performance offered by these tubes versus what was available thirty plus years ago is amazing. Tube performance from U.S. manufacturers has shot up across the board. L3Harris has been able to increase average FOM (figure of merit) performance alone by over 50% in the last six years. With the release of the SuperGain tubes, TNVC is able to offer the most advanced, most high performance, MIL-SPEC night vision systems currently available to our customers—BOTH government and commercial.”

TNVC MIL-SPEC SuperGain Systems will be available in all TNV-branded night vision systems, including the TNV/BNVG-M Artemis, TNV/DTNVS, TNV/RNVG, and TNV/PVS-14 as well as L3Harris-manufactured BNVD (PVS-31) and BNVD-1531 systems, all with an increased 2376+ Minimum Figure of Merit (FOM) specification. These new units will exist alongside current TNVC offerings, including those with standard Unfilmed and Filmed image intensifier tubes.

tnvc.com/supergain

***SuperGain tubes are currently IN-STOCK for all TNV-systems. L3Harris systems will be available for Pre-Order***

All TNV-Night Vision Systems are semi-custom built-to-order units, please allow approximately two weeks for order-processing and assembly. Existing order changes are on a first-come, first-served basis. Hand-select is available for TNV-systems.