I have been surrounded by tactical gear for most of my adult life. I appreciate, use, buy, care for, and even customize tactical gear. But, I’ve never tried to make tactical gear. Then, I found Canvasworker.com. My discovery dropped me into a “safeties off” industrial sewing class, at a leading bag design company, with a vibrant community of creatives and makers dedicated to advancing the craft. For four full days, I explored pattern making, sewing techniques, materials, and bag making principles under the guidance of a master – complete with cutting edge materials and machines in his bag design workshop. At the end of the course, I had made my very own tactical backpack. It was such an impactful, productive and spiritual (yes, spiritual) experience – I had to share.

THE BROWN BUFFALO

I purchased a seat and made my way to Canvasworker.com’s renowned backpack making class in March 2024. I was met by the host, Douglas Davidson, the legendary maker – known as the “Brown Buffalo”.

Few people share Douglas’ experience in the bag making industry, here in the U.S. or overseas. His journey spans the last 25 years where he worked at top industry brands Burton, The North Face, Nike, Adidas, and Beats to name a few. Douglas runs The Brown Buffalo, a luxury bag company that designs and manufactures purpose-built backpacks and accessories for leading brands, military personnel, law enforcement, first responders, Tier 1 athletes and music artists.

Douglas also consults on trend forecasting, innovation, product design, product development and manufacturing support around the bag industry.

Douglas is a maker. He is a master of bag design, and a man committed to freely share his knowledge and perspective. Douglas’ nature and rapport is straight up spiritual, yet he remains as no-frills and no-nonsense as you could get. He is a coffee-fueled, ocean-powered, bag sewing guru.

THE BAG MAKING EXPERIENCE

I arrived at the workshop, in a trendy mixed use commercial and industrial part of Costa Mesa, CA. There were only two other students in my class, each of us with completely diverse origins and expectations. The workshop is an open, high-bay space dripping with signature fabrics and high-quality material. Up high on all three walls extends a line of backpacks hung together in what amounts to a global trek through adventure backpack history. Some of the packs are one of a kind, some are antiques … but every stitch, zip and pocket of these bags holds a story.

Down the center floor of the shop are a dozen, Japanese-made, Juki industrial sewing machines. When you get behind one of the Jukis with pneumatic assist (and give your complete trust to the machine) even a novice can demonstrate some strong sewing chops.

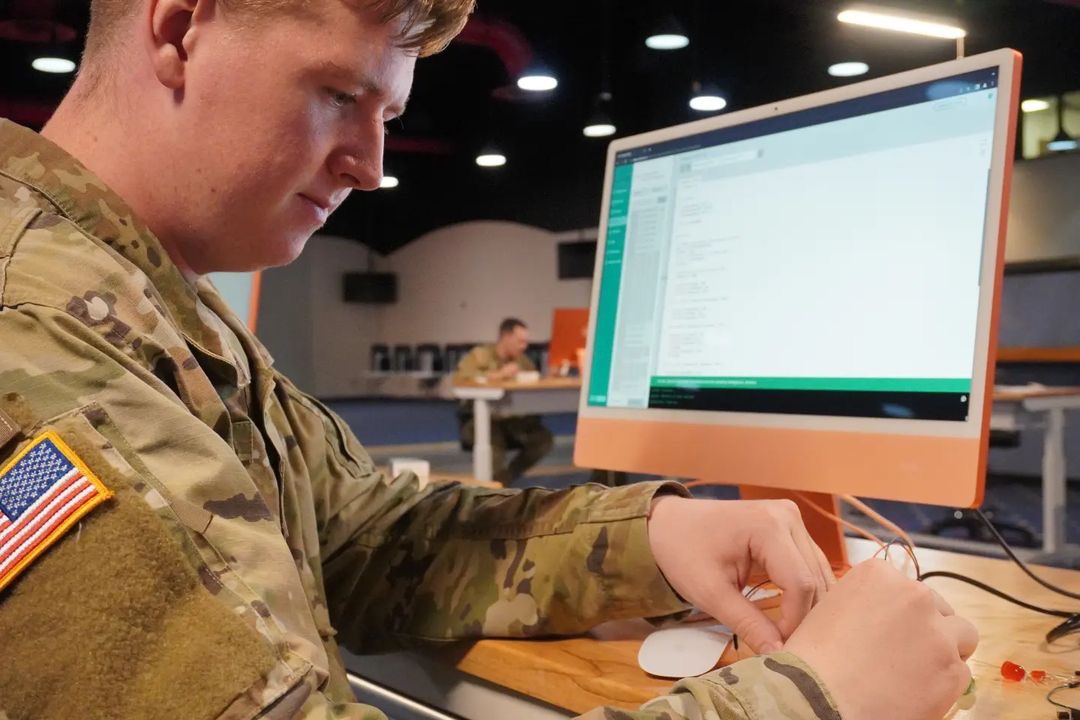

For four days, we split our time between a hightop layout table and our Juki. The first project we crafted was a tote bag. Each of us selected a series of custom fabrics – I chose fabric from Dimension Polyant, a German sail and advanced fabrics manufacturer (a favorite of Davidson). The tote was our test case, to learn the patterns, layout and of course to get to know our Juki.

Douglas’ prime directives were “open mindedness is critical” and “trust the machine”. He was a constant presence over our shoulders, but also was fine with letting us learn on our own. On the second day, we progressed from our tote to begin the process of making and assembling our tactical backpack. We learned the core components and key approaches for crafting a high-quality bag. Every base sewing component had to be perfect in order for the final product to line up correctly. When we messed up, it was obvious, and each of us had to de-stitch an essentialbag component at least twice … for me, at least four times.

As we worked diligently on our creations, Douglas regaled us with tales of his own adventures working in Chinese and Vietnamese bag factories in the 90s, then to his colorful youth in East LA, growing up around Lowrider culture, gang violence and big wave surfing. He was as comfortable talking about the punk rock band Black Flag or the best websites to bulk order vintage military camo prints and rifle sling quick release points – all of this was mesmerizing stuff for me.

Each day our backpack took shape, and by the close of the fourth day I had made my final product. I had never created anything by sewing – but now I had made an industry-standard concealed carry backpack, in MultiCam Black.

Your time at Canvasworker.com is not all work. We did have to sustain ourselves and the workshop is surrounded by eclectic shops, breweries and restaurants, all in the hip area of The Camp and The LAB Anti-Mall. We had daily coffees at Work In Progressand some amazing lunches at Memphis Cafe Memphis Cafe, Green Cheek Beer Co. Green Cheek Beer Co. and Rooster Cafe Rooster Cafe

A NEW CONNECTION TO MAKING

Creating something, and watching it take form with quality materials and craftsmanship was intoxicating. I was nervous about sewing, but constantly curious and thrived in the Canvasworker.com environment. Douglas and his team are dedicated to American Manufacturing and werethere to help me start my own journey. That is where the spiritual piece comes in. Making has a vital place in our modern lives. A robot can not yet sew a high-quality backpack. Douglas’s passion for craftsmanship and exploration ignited a fire within us all, spurring us on to make more. Learning how much gratification I could take from making a backpack (of all things) made this experience so worth it. I encourage you to check it out.

– Jason Salata