Archive for May, 2024

Meet with OKSI at SOF Week

Wednesday, May 1st, 2024MDM 24 – Brunton Announces Lensatic Compass

Wednesday, May 1st, 2024Brunton has been making compasses since 1894 but they’ve never offered a mil-spec, tritium-filled compass, until now.

Coming in 2025, their new Lensatic Compass features a needle which settles 30% faster than the current compass and a durable bezel which will continue to click throughout the life of the compass.

Although their pouch is similar to the current issue model, which is based on an M-1956 design, carried on through ALICE, this new version is PALS compatible.

On a final note, although it has been in Montana for over half a century, Brunton was owned by various Scandinavian businesses for many years. About two years ago, Brunton became a woman-owned, geologist-owned, family small business.

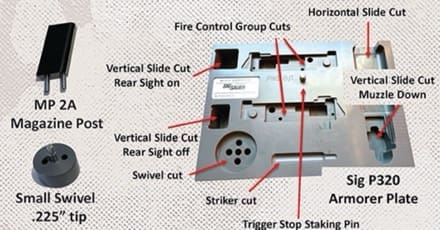

MDM 24 – M17-M18-P320 Armorer’s Platform Kit from Pro-Shot Defense

Wednesday, May 1st, 2024The Modular Handgun System is essentially fully fielded across DoD and multiple federal, state, and local agencies issue the SIG P320.

Its modular design means quite a lot can be done by the local armorer or even the individual if authorized by the issuing agency.

At the request of users, Pro-Shot Products has developed an Armorer’s Platform which offers a stable base to hold the pistol in place while various parts are replaced. Additionally, there are cut-outs for all major components.

The kit comes complete with the armorer plate, magazine swivel mount, and magazine post.

Coming soon from Pro-Shot Products.

Top photo by David Jordan, Marine Corps Systems Command. Use of this photo does not only endorsement by the Marine Corps.

2024 Modern Day Marine

Wednesday, May 1st, 2024

Welcome to our coverage of the 2024 Modern Day Marine Exposition held in Washington, DC. The Marine Corps is well on their way into their Force Design 2030 process which is transforming he Marine Corps at all levels.

Man Lift USA Stands Ready to Fulfill Explosion Proof (EX) Rated Material Handling Equipment (MHE) Requirements

Wednesday, May 1st, 2024

As new Explosion Proof (EX) rated Material Handling Equipment (MHE) requirements and regulations become more stringent across military and commercial sectors, Man Lift USA stands ready to fulfill needs of end users and program offices for EX compliant MHE.

Man Lift USA designs and manufactures specialty aerial access and material handling solutions. We have been providing lift and access equipment for the most unique, hazardous, and challenging environments since 2000.

Our material handling equipment is designed to boost productivity and ensure safety in demanding work environments. We offer a range of products such as boom lifts, scissor lifts, material lifts, and mobile cranes to develop tailor-made solutions for your facilities, aircraft, ship, or rocket construction and maintenance.

Our flagship products are our EX rated articulating boom and scissor lifts. However, we also offer several other electric, electrically insulated, Track-Driven, and more traditional MHE solutions for customers in addition to our EX rated line of products.

Man Lift USA’s equipment is recognized as the gold standard and utilized extensively across the aerospace, shipbuilding, chemical, and construction industries in addition to aircraft maintenance, facilities maintenance, painting, fuel cell work, or any environment where explosion hazards may exist. Our EX rated lifts meet and exceed safety requirements working in and around enclosed spaces, ordinance, paint vapors, or volatile fuels and chemicals.

Our lifts have longer run times between charging cycles than the competition and offer essential options such as aircraft protection kits, collision protection kits, omnidirectional steering, and vertical access platform accessories as well.

For sales inquiries or additional information please contact:

Landmine Detection and Neutralization: Breaching Ain’t Easy

Wednesday, May 1st, 2024Landmines have been used in warzones for decades. They are placed strategically in the pathway, both surface-laid and underground to explode and deter passage to an area. In those decades various methods have been used to detect and defuse them yet each year thousands of people are killed by mines.

The U.S. Army is exploring methods to detect and neutralize these hazards at standoff creating a passable vehicle wide lane while reducing risk to the breaching force.

Amit Makhijani with the office of Project Manager Close Combat Systems explained “We are doing dynamic live fire testing on one potential concept as part of the Technology Maturation and Risk Reduction efforts.”

That concept is the GOBLN short for Ground Obstacle Breaching Lane Neutralizer. It allows remote detection and neutralization— meaning the warfighter would not be at risk.

The concept is comprised of three main components. A mortar-based launcher system integrated on a vehicle platform, a small unmanned aerial system hosted detection system, and a neutralizing munition.

For this dynamic neutralization test at Yuma Test Center (YTC) the team focused on the neutralization aspect.

“What we are looking at is not what the gun is doing, it is what is it doing on the other end. What are the effects on the mines we are shooting at,” explained YTC Test Officer Brett Bowman.

YTC provided a wide area laid out with six lanes of high explosive mines with inert fuzes comprised of both US M-15 and foreign TM-62M. The team placed the mines strategically atop a tarp to track how the mortar shrapnel hit each mine and the surrounding area.

“When we go out an assess, we mark each target, so when we fire on them again, we know which ones it hit on the first time and we will know the difference between the first time and the second,” explained GOBLN Test Lead Raj Nattanmai with the U.S. Army’s DEVCOM Armaments Center (AC).

Bowman adds, “We are getting the observer data to know where they impacted, then after each sequence we go out and do inspections to see the damage on targets and access how we did.”

This allows the DEVCOM AC personnel to better model the down range effects with real world shot data and adjust the launcher as needed.

In this proof-of-concept phase, the team is looking for specific criteria.

Nattanmai described, “We want the shrapnel to come in and pierce the mines so that it damages either the fuse or sets it off. The other possibility is that it creates a reaction and causes it to burn.”

Nattanmai showed the team a TM 62 mine that was completely burned and explained, “That one didn’t blow up, it burned. It set on fire and charred up basically. That’s the ideal neutralization. That’s what we want all the targets to do.”

Bowman came up with the placement of the mines to provide efficient testing in between mandatory safety wait times.

“They were originally going to have one mine lane, we shoot, go out inspect, and come back. We can’t do that because of the wait times. So, what I did was set this one up so we can have multiple mine lanes, fire multiple engagements at a time, then that way we can go out and inspect them after the certain amount of wait times.”

This method shorted the firing window to three weeks versus a month and a half. When all was said and done the team fired more than 250 mortars at targets.

The GOBLN is one of the many solutions the Army is testing to see which the most effective solutions are to meet modern threats.

Army Futures Command Capabilities Developer Shawn Anders remarks, “In the concept of the future, we are not talking about what we can do today. What we are trying to do, the next 10 years, 20 years down the road and have that forecast. So today is just our baseline of multiple systems, for consideration for the future. And like Maj. Thomas Fite said, ‘Breaching Ain’t Easy.’”

By Ana Henderson