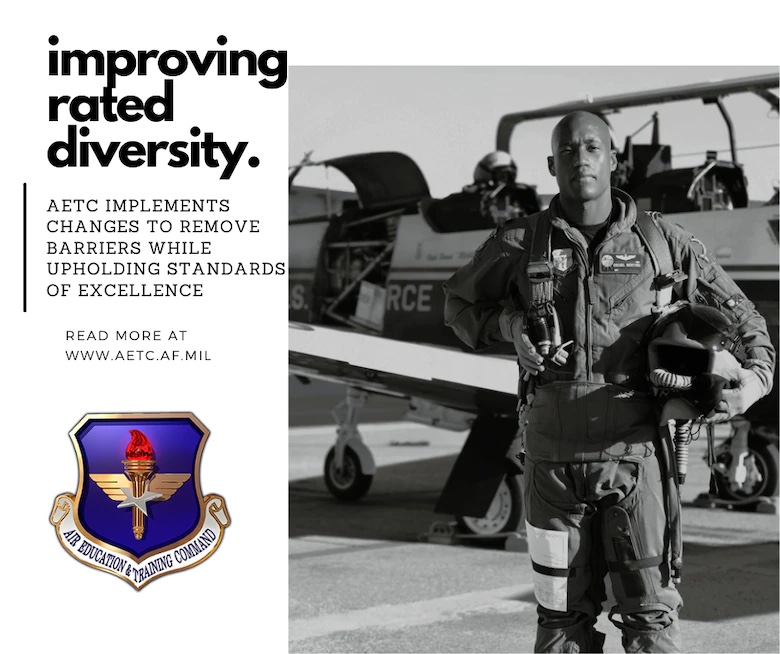

JOINT BASE SAN ANTONIO-RANDOLPH, Texas — Several Air Education and Training Command initiatives to remove barriers for qualified candidates in the pilot candidate selection process were highlighted in the Air Force’s six-month assessment of its initial Racial Disparity Report Sept. 9.

Pilot Candidates may now:

– Use their highest composite scores from any Air Force Officer Qualifying Test (AFOQT) rather than the most current score.

– Complete the Test of Basic Aviation Skills (TBAS) up to three times, with the third requiring a waiver from the applicant’s wing commander or equivalent.

– Re-take the AFOQT and TBAS after 90 days compared to the previous 150-day requirement for the AFOQT and 180 days for the TBAS.

– Participate in study sessions with other individuals who have not yet taken the test if the examinee has also never taken the AFOQT.

These changes came after extensive research conducted by the pilot selection process working group responsible for identifying potential barriers while upholding the standards of excellence in the Pilot Candidate Selection Method (PCSM) used since 1993.

“Our studies concluded that these changes will result in more qualified candidates of underrepresented groups being selected for training,” said Lt. Col. Brandi King, the working group’s Air Education and Training Command lead.

Prior flying experience a barrier to qualification

Prior flying experience, the second largest component of an applicant’s PCSM score, particularly poses a socioeconomic barrier to candidates without access to or financial means to pay for flying lessons. To address this barrier, the Air Force now considers only a candidate’s initial 60 flight hours when scoring a candidate.

“There is no evidence that more than 61 hours of flight experience poses a significant benefit to pilot training success,” said Dr. Katie Gunther, chief of strategic research and assessment at the Air Force Personnel Center. “The probability of success in flight training increases substantially from 0 hours to 60 hours, then relatively plateaus.”

The working group also found that removing the higher ranges of flight hours as part of the PCSM score would result in a more-diverse applicant pool. According to the Validation of the Pilot Candidate Selection Method 2020 report prepared by the AFPC Strategic Research and Assessment branch, removing the four highest ranges of flight hour codes would have resulted in 69 more Hispanic, 47 more female, and 26 more Black/African-American qualified applicants over a 12-year period.

“Flying lessons are expensive and could potentially exclude qualified candidates from becoming pilots in the Air Force due to limited income or lack of opportunities,” said Brig. Gen. Brenda Cartier, AETC’s Director of Operations and Communications and the pilot selection process working group’s overall lead. “In order to ensure we do not eliminate otherwise qualified candidates, flight programs have been implemented at both The United States Air Force Academy and the Air Force Reserve Officer Training Corps. Cadets receive free ground and flight training, and an opportunity to gain critical skills and directly improve their competiveness for pilot selection boards.”

Pilot selection process

A PCSM score quantifies a pilot candidate’s predicted aptitude for success at undergraduate pilot training. This score is comprised of the AFOQT and TBAS scores, previous flying experience, and other “whole-person concept” merits such as grade point average, physical fitness assessment scores and class ranking.

“Data supports that the PCSM is the best single predictor of pilot training completion. However, it is imperative that we continue re-evaluating our selection methods and remove barriers that hinder rated diversity without compromising test integrity or lowering standards,” King said.