Naval Surface Warfare Center, Crane Division (NSWC Crane) has designed and developed the Drone Killer Cartridge (DKC), a new and cost-effective family of ammunition for the warfighter that increases probability of hit and kill against drone threats while inherently reducing collateral damage.

“We’re enabling extended range, shotgun-style effects through automatic rifles and machine guns with nothing more than an ammunition change,” said Brian Hoffman, Man-Portable Weapons Chief Engineer at NSWC Crane.

DKC is an ammunition technology that disperses a cluster of projectiles upon firing—for rifles, automatic rifles, and machine guns—with far greater range than a conventional shotgun. These effects increase the probability of hit and kill against Unmanned Aerial System (UAS) threats in a way that also reduces the risk of collateral damage for any projectiles that don’t impact the target. During a recent demonstration at Camp Atterbury in Edinburgh, Indiana, DKC achieved a 92% success rate against drone targets.

Col. Andrew Konicki, Program Manager of Ground Based Air Defense for Program Executive Officer Land Systems, said the Marine Corps plans to broadly leverage DKC for its enhanced capabilities and implement at the operator-level.

“The Drone Killer Cartridge represents a pivotal shift in countering the pervasive threat of enemy drones,” said Col. Konicki. “This type of ammunition provides an immediate and significant improvement to our kinetic kill capabilities by using standard-issued weapons that are already in the hands of Marines. The collaborative work between NSWC Crane and the Marine Corps has positive impacts across the ecosystem of Homeland Defense as well as self-protection for our forward deployed troops in harm’s way. With DKC, we are adding capability well beyond conventional options, while also bending the cost curve for neutralizing drone threats, particularly to the individual Marine. Crucially, its design reduces the risk of collateral damage, making it a dominant and urgently needed solution that will fundamentally change the fight for every Marine.”

Unmanned systems are reshaping tactics, challenging established operations, and creating life-threatening threats for warfighters globally. To counter this rapidly evolving and critical threat, the Department is aiming to improve overall defense capabilities.

“By design, DKC provides broader terminal coverage on and around the intended target, which increases effectiveness against stationary and moving drones by helping offset imperfect aim,” said Hoffman. “There’s a good reason why bird hunters use shotguns. We’ve applied a similar philosophy to killing drones while amplifying overall performance. DKC sub-projectiles exit the barrel at velocities typical of centerfire rifle ammunition. Those velocities, and associated energies, far exceed shotgun capabilities and serve to extend effective range while offering more devastating effects on target.”

DKC technology provides an improved defense capability at an affordable price, ensuring versatility for end-users with rapid integration for a variety of mission sets. Engineers and technicians developed DKC from internal NSWC Crane Naval Innovative Science and Engineering (NISE) funding and Department of Homeland Security and Marine Corps investment. Because use of DKC involves only an ammunition change, timeline to initial fielding can be accelerated as it does not require qualification of a new weapon system. As a beneficial side effect of that approach, DKC eliminates the need for warfighters to carry excess weight of an additional weapon dedicated to countering drones.

“When you compare the cost it takes to kill a drone using DKC versus some other solutions that are being employed, it’s a night-and-day difference,” said Hoffman. “The projectiles used in segmented DKC and pelletized DKC are both inert, meaning there is no energetic material in the projectile itself. The separation mechanisms are purely mechanical, and the cartridge case, primer, and propellant are common to other ammunition types already in production. These attributes combine to help keep it elegantly simple yet effective while ensuring low-cost producibility.”

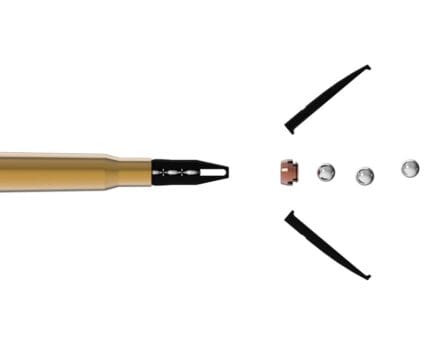

All DKC products are NSWC Crane-designed and U.S. Government-owned intellectual property (IP) with U.S. nonprovisional utility patent applications and Patent Cooperative Treaty applications on file. The DKC family includes both Pelletized and Segmented product options. There is functional overlap between the two, though each type maintains unique priority rankings for effective range, target area coverage, suppressor compatibility, and cost. Segmented DKC includes a one-piece projectile that mechanically self-separates into discrete, spin-stabilized sub-projectiles prior to muzzle exit whereas Pelletized DKC includes a projectile assembly containing a stack of high-density, spherical buckshot-sized pellets that are mechanically disbursed at muzzle exit.

Hoffman said the technology enables the end-user to quickly dispatch UAS threats.

“The intent with our ammunition was to simply give operators a better chance of killing drones with cost-effective products that can be used in existing weapons. If you aren’t the world’s best shot or don’t have a lot of experience engaging aerial targets, your odds go up immediately with DKC. As a bonus and since these products are already mature, you won’t have to wait years for product development in order to access DKC and put it to good use.

Hoffman said the DKC team and NSWC Crane family are excited and motivated to fast-track these products to the field and fleet to help meet urgent needs – not just for the Navy, Marine Corps, and DHS – but for the other U.S. Military Services, Government Agencies, and select foreign partners.

“The demand signal for DKC is increasing dramatically given the current threat environment and the more we socialize these products and the technology,” said Hoffman. “There are obvious reasons why it resonates with military operators and Counter-UAS stakeholders who understand the urgent need. DKC is effective, it’s affordable, and it can be used immediately with weapons that are already in service.”

To view some footage of drone kills using DKC, high-speed video of the sub-projectiles as they exit the barrel, and additional introductory content.

The Drone Killer Cartridge technology is available for licensing to commercial ammunition and defense manufacturing partners. Initially designed for military applications, there also are applications for home defense, personal protection, and hunting. To learn more about the IP and licensing opportunity, please visit TechLink.

Rheinmetall is further expanding its role as a leading manufacturer of 120mm tank ammunition. The NATO Support and Procurement Agency (NSPA) has called off its first batch of ammunition, worth around €200 million, under a 2025 framework agreement for 120mm ammunition, a contract of substantial scope and value. The end customers are various NATO countries.

Rheinmetall is further expanding its role as a leading manufacturer of 120mm tank ammunition. The NATO Support and Procurement Agency (NSPA) has called off its first batch of ammunition, worth around €200 million, under a 2025 framework agreement for 120mm ammunition, a contract of substantial scope and value. The end customers are various NATO countries.