PICATINNY ARSENAL, NJ — Secretary of the Army Dan Driscoll, Senior Official Performing the Duties of the Deputy Under Secretary of the Army David Fitzgerald, and U.S. Representative Thomas Kean Jr. visited Picatinny Arsenal on November 6 to see first-hand the innovative work being by the Joint Program Executive Office for Armaments and Ammunition (JPEO A&A), U.S. Army Combat Capabilities Development Command (DEVCOM) Armaments Center, and Office of the Project Manager Soldier Lethality as they strengthen the Arsenal of Freedom by increasing industrial capacity and bringing advanced technologies and improved lethality to the Warfighter. The visit was Driscoll’s first to Picatinny, which is designated as the Department of War’s Joint Center of Excellence for Guns and Ammunition.

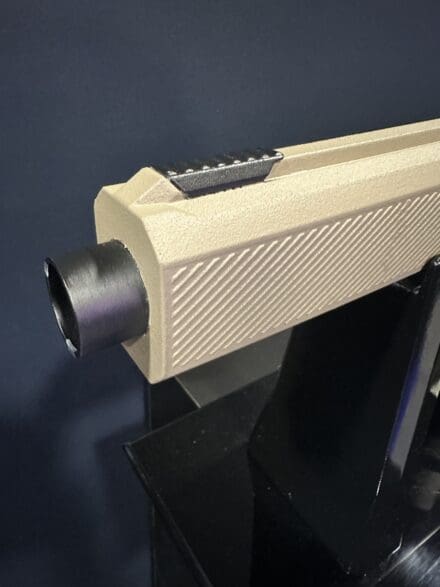

The visit began with a hands-on demonstration of the lethality of the 6.8mm ammunition for the M7 Next Gen Squad Weapon. The rounds will be produced at the Lake City Army Ammunition Plant outside St. Louis in an interim capacity until completion of a new, state-of-the-art facility that is currently under construction. Sig Sauer is also producing the new rounds as a second source in Jacksonville, Arkansas. DEVCOM and JPEO engineers explained to Secretary Driscoll the various 6.8mm technical innovations and the new ammunition’s performance specs as compared to currently fielded 5.56mm and 7.62mm capabilities.

Developed collaboratively by the JPEO A&A, the DEVCOM Armaments Center, the Army Research Laboratory, the 6.8mm family of ammunition is specifically engineered to maximize the performance of the M7 Rifle and the M250 Automatic Rifle. When fired through these Next Generation Squad Weapons, 6.8mm rounds deliver increased range, improved accuracy, and enhanced lethality, ensuring Soldiers maintain overmatch on the battlefield.

Driscoll attended a working lunch where Maj. Gen. John T. Reim, Joint Program Executive Officer for Armaments & Ammunition and Picatinny’s Commanding General, and other senior leaders highlighted the diverse capabilities and critical missions of the major commands and tenant organizations at the installation, underscoring Picatinny’s enduring role in supporting joint force operations and sustaining combat power.

“I have had the privilege of doing nine ribbon-cutting ceremonies here in the past two years,” Reim said. “We are bringing new capabilities online. We are replacing legacy production methods and working closely with industry partners to develop modular, flexible production capabilities that can support a surge while maintaining efficiencies during downtimes.”

The visit continued with a bang as Driscoll witnessed a live fire exercise featuring the Purpose Built Attritable System (PBAS) and a TRV-150 drone dropping smoke and a M69 training grenade onto a target simulating a small group of enemy soldiers with a vehicle. This showed off one of DEVCOM’s latest innovations, the Picatinny Common Lethality Integration Kit or Picatinny CLIK, which defines the physical interface (mechanical attachment), electrical interface (power, network, messaging) and safety critical architecture between the ground station control and an unmanned aerial system (UAS) with lethal payloads, eliminating unique integration methods and costly acquisition conditions created by “vendor lock.”

“This ensures a rigorous, yet flexible, process for evaluating, qualifying, procuring, and ultimately fielding safe and effective weaponized UAS payloads to the joint force,” said acting Executive Director of the Armaments Center’s Weapons and Software Engineering Center, Bhavanjot Singh. “When we solicit industry for a capability, we will be providing Picatinny CLIK technical data so industry can focus on providing lethal capabilities without worrying nearly as much about integration.”

Following the live fire demonstration, Driscoll was shown more of the unique capabilities developed at Picatinny Arsenal by the DEVCOM Armaments Center and the Project Manager offices under JPEO A&A covering lethal UAS, counter-UAS munitions, advanced artillery, and next-gen energetics.

One highlighted counter-UAS capability was the airburst proximity fuze technology that was initially fielded in 30mm XM1211 High Explosive Proximity (HEP) for M-LIDS, providing the first medium caliber counter-UAS capability to theater. Leveraging the capability, the proximity fuze technology was scaled down to a 25mm form factor for the XM1228 Bradley Aerial Defeat Ground Enhanced Round (BADGER). BADGER provides organic C-UAS capabilities to the M2 Bradley Infantry Fighting Vehicle with no additional vehicle or weapon modification required.

“BADGER is a great example of how the Army’s acquisition enterprise is moving toward quicker returns by leveraging new ways of doing business, quickly innovating at the round, and leveraging existing weapons platforms to enhance the lethality of our Warfighters,” said Reim.

Another counter-UAS capability developed at Picatinny Arsenal and presented to Driscoll was the next generation Common Remotely Operated Weapon Station (CROWS). The implementation of a C-UAS capability for platforms with current or future CROWS allows for leveraging of existing 30mm and 40mm weapon systems and proximity-fuze ammunition, providing a low-cost kinetic C-UAS solution across multiple platforms.

Artillery innovations as part of the Army’s Long Range Prevision Fires line of effort are another critical capability area at Picatinny that was presented to Driscoll.

The M982 Excalibur is a 155mm Global Positioning System (GPS) guided precision cannon artillery munition compatible with 39-caliber, 52-caliber and 58-caliber artillery systems with reach distances of up to 40 kilometers, 50 kilometers and 70 kilometers, respectively. Excalibur was co-developed by Raytheon and BAE Systems Bofors and is currently in production to deliver projectiles to the US Army. The projectile is being evaluated for system upgrades to improve performance in GPS-jammed environments leveraging lessons learned and telemetry data from Ukraine.

The Extended Range Artillery Projectile (ERAP), also known as the XM1155 program, is a cutting-edge system of systems designed to deliver unprecedented lethality and range overmatch for 155mm artillery weapon systems. With ranges exceeding more than double those of legacy artillery cannons, the ERAP will be compatible with both current and future Army mobile howitzer systems. The ERAP program is being executed through the innovative Middle Tier of Acquisition pathway, which leverages both traditional and non-traditional suppliers. This approach fosters competition among industry partners and accelerates the prototyping of mature technologies, ensuring that hardware is delivered to Soldiers faster and more effectively.

The Modular Artillery for Combat Effectiveness (MACE) program was discussed, which is an effort to focus on making conventional artillery more manufacturable and modular. Enhanced manufacturability will reduce dependency on niche, government only production processes and leverage commercial production capabilities and capacity.

Following the tours and demonstrations, Driscoll presented coins to the various organizations.

The Secretary of the Army’s visit to Picatinny underscored the installation’s vital role in sustaining the force and arming the Army of the future. As the Army continues to modernize and adapt to evolving global demands, the various commands at Picatinny Arsenal remain a pillar of readiness – delivering the capabilities, expertise, and innovation that ensures our Warfighters and allies are equipped to succeed in any environment.

By Michael Chambers