Belgian textile manufacturer SEYNTEX showed off a 3D printed lightweight plate carrier concept.

Here you can see lattice work which adds padding and airflow.

Belgian textile manufacturer SEYNTEX showed off a 3D printed lightweight plate carrier concept.

Here you can see lattice work which adds padding and airflow.

PARIS — Integris Composites, the global leader in armor protection for the world’s elite military and law-enforcement units, will display its new “make your own shield” concept and soft body armor vests at Milipol Paris 2023 Stand 5 F009, taking place Nov. 14–17 at the Paris-Nord Villepinte Exhibition Centre.

“We are presenting two innovations,” said Jan Grimberg, the senior vice president of marketing and sales EMEA at Integris, “a new product line of body armor vests with our Rapid Don/Doff system that is an industry first and a new line of customizable ballistic shields.”

Integris, the new name for TenCate Advanced Armour, is continuing the company’s quarter-century emphasis on safety, reliability and survivability.

Make Your Own Shield Concept

The new shield line is designed to respond to law enforcement and military organizations, which frequently want designs tailored to their procedures.

Shields Up! Integris Composites – the new name for TenCate Advanced Armour — is introducing new police and military tactical shields at Milipol Paris 2023, Stand 5 F009, from Nov. 14-17 at the Paris-Nord Villepinte Exhibition Centre. Visitors can view a new line of customizable ballistic shields as well as a new version of the Integris Composites CXP Ergo Shield shown here.

“Bespoke solutions are nothing new for Integris Composites, but in the past, small-quantity, custom shield orders had to contend with the entire industry’s inherent need to tailor-make molds for every version—cost prohibitive for small orders,” said James Williamson, Integris Composite’s sales manager for France, Spain and Portugal.

The addition of new equipment in the past year enables Integris to make shields that are specific to a customer’s needs for shape, size and weight, but with a significantly shorter lead time and at a price like that of larger series. “Our new manufacturing capability reduces the nonrecurring costs (NRC) of molds. This makes one, two or a few handheld portable shields completely feasible,” explained Williamson.

Two operators standing before the autoclave at the Integris Composites facility in France inspecting a ballistic armor plate. Formerly TenCate Advanced Armour, the company is introducing new products at Stand 5 F009 Milipol Paris, Nov. 14-17 at the Paris-Nord Villepinte Exhibition Centre.

A Dream Capability

“This is a dream capability. Now, as a customer, you have a choice. You can buy something off the shelf from our catalog. Or you can buy a customized solution that’s a lot more affordable than it was in the past,” said Williamson.

Custom products are especially appealing to law enforcement and military since many units require specifications in size, weight and shape to allow active members to perform their duties with a focus on safety and durability. “They don’t have to buy a million euros worth of product to get exactly what they want. They do not have to buy thousands of units to get exactly what they want. They can get exactly what they want when ordering a few units,” added Williamson.

Testing New Rapid Don/Doff Vests

Throughout the show, Integris invites active members of law enforcement and the military to try on Rapid Don/Doff armor vests, which are making their public debut here.

These vests use a magnetic buckle system. “They can take it off, put it on in two seconds without losing their settings,” said Stephen Jackson, regional director of Turkey, the Middle East and Africa. “This enhances safety, comfort and predictability.”

Special Pride

“There is a special pride in participating in Milipol,” said Grimberg. “We are a truly international company. With 25 percent of our workforce in France, we are proud to have the opportunity to display these two innovations in Paris under the banner of a new name,” said Grimberg.

Build Your Own Set

The Guardian Plate Carrier is a modern vest designed for carrying ballistic plates with the option of attaching additional gear thanks to its modular system compatible with MOLLE/PALS. The Guardian series includes the vest and 16 components that can be configured as you like. The Guardian Plate Carrier allows for carrying plates in the most popular standards: E-Cut (SAPI/ESAPI), Swimmer Cut, and Shooter Cut.

Elements of the Guardian Series:

To better tailor the products to users needs, we’ve prepared several components designed for various activities. Two types of cummerbunds: standard Guardian Cummerbund and Guardian Cummerbund Quick Release. For carrying equipment at the front, there is the Guardian Kangaroo Flap with hook & loop and the Guardian Flap equipped with MOLLE/PALS straps with room for three AK/AR magazines.

Specifically for police and similar services, we’ve developed the Law Enforcement Insert, which will accommodate two pistol magazines, a radio, and handcuffs. In addition, the Guardian series features two pockets for grenades: the Smoke Grenade Pouch for smoke grenades and the Flash Grenade Pouch for flashbangs.

Efficient organization of equipment is provided by various types of pouches and pockets: Double Horizontal Pouch for rifle magazines, Pistol Magazine Pouch for a single pistol magazine, Universal Pouch for flexible gear storage, Guardian Dangler drop pouch, and Radio Pouch for storing a radio unit. Also available in the series is the Guardian Admin Pouch, a universal tactical Mini Pouch, and the Tourniquet Pouch.

Anything that doesn’t fit at hand can be carried in the Guardian Smallpack with a 7.5 l capacity, which can be attached to the plate carrier thanks to detachable straps. The backpack opens almost entirely and has a separate pocket for a hydration insert.

OR CHOOSE A PRE-MADE SET

In addition to individual components, Helikon-Tex also offers complete sets tailored for specific types of services: the Guardian Military set designed for the armed forces comes with the Guardian Cummerbund and the front Guardian Flap. The Guardian Law Enforcement set was developed with the police and other uniformed services in mind. The base element here is the tactical Guardian Plate Carrier vest. It comes with a Guardian Cummerbund, a front Guardian Kangaroo Flap, and a dedicated Law Enforcement Insert.

NFM Group is proud to announce its partnership with the Canadian Special Operations Forces Command (CANSOFCOM) and Defence Research and Development Canada (DRDC) for an R&D program focused on the design and development of innovative hard ballistic plates.

Ski, Norway, November 8th 2023: The contract, awarded in September 2023, initiates a two-year development phase, with the first delivery anticipated for 2025. In a forward-thinking move, this contract also includes a provision for a seamless transition to immediate pre-approved procurement upon successful completion of the development phase. This eliminates potential gaps in delivery timelines and ensures that CANSOFCOM members are equipped with the latest protective gear without delay.

“We’re incredibly honored to collaborate with CANSOFCOM and DRDC in redefining the future of hard ballistic plates. This contract is a testament to NFM Group’s commitment to innovation and our relentless pursuit of safeguarding those on the frontlines”, says Cyril Veillat, Director Body Armor Systems, at NFM’s Product Integration Unit.

“We’re incredibly honored to collaborate with CANSOFCOM and DRDC in redefining the future of hard ballistic plates. This contract is a testament to NFM Group’s commitment to innovation and our relentless pursuit of safeguarding those on the frontlines”, says Cyril Veillat, Director Body Armor Systems, at NFM’s Product Integration Unit.

Reinventing Hard Ballistic Plates for Modern Warfare

NFM Group aligns with CANSOFCOM’s core belief that its most valuable resource is its personnel. As the diversity within the Canadian Armed Forces continues to grow, there is an increasing need for ballistic plates designed to accommodate a wide range of body types.

“Our upcoming hard ballistic plates will leverage cutting-edge materials and feature a revolutionary multi-curve design to fit various body shape, especially female ones. This enhances both fit and protection, safeguarding vital organs and points more effectively. Furthermore, the new plates will be lighter than their predecessors, fostering increased comfort, mobility, and functionality across varying roles, missions, and threat levels”, says Veillat.

The design process will be data-driven, incorporating anthropometric data from diverse body types benefitting from DRDC’s extensive expertise in personal protection and laboratory testing infrastructure. Rigorous testing before and after acquisition will validate that the new plates meet or exceed all ballistic limit requirements.

NFM’s Advanced Capabilities in Ballistic Protection

NFM Group’s vision is to protect individuals against both man-made and natural threats, regardless of the environment. Our Ballistic Department has specialized in end-to-end design and development of a wide array of ballistic protections since 2006, ranging from soft panels to hard plates and trauma protections.

“Our in-house ballistic test laboratory allows for immediate performance verification, accelerating the R&D process in a controlled environment. Utilizing unique, state-or-the-art technology such as FREC II, we’ve optimized our offerings to provide lightweight protection that supports mobility and enhances the survivability of frontline soldiers”, says Veillat.

This contract marks a significant expansion of NFM Group’s footprint within North America’s Special Operations Forces community and serves as a pivotal moment in our growth strategy.

By fusing our innovative technologies and deep industry experience with CANSOFCOM and DRDC’s insights, we aim to set new standards in ballistic protection and fortify our commitment to the safety and effectiveness of military and law enforcement personnel.

NFM is looking forward to revealing the GARM™ Ballistic Underwear on the global stage at Milipol 2024 in Paris. This product sets a new standard by offering soldiers dual benefits: unparalleled protection against serious blast injuries and long-lasting comfort for extended wear.

The NFM GARM™ Ballistic Underwear has already proven invaluable in protecting against high-speed secondary fragments up to 200 m/s. Developed by our subsidiary, Hexonia, this technological innovation is the result of a three-year R&D process led by Product Developer Eva Goral.

“This isn’t just another piece of tactical clothing. It’s designed to save lives without compromising comfort. What makes it truly unique is that you wouldn’t know it’s lifesaving ballistic underwear just by feeling it— it’s that comfortable,” says Goral.

Unmatched Comfort and High-Strength Material Blend

Our ballistic underwear not only defends against secondary injuries from blasts, but also such as those caused by IEDs, and integrates materials that maximize wearer comfort. High-performance fibres like silk, polyamide, and elastane are combined to provide both ballistic protection and a snug and comfortable fit.

“The silk has a particularly high strength and feels pleasantly cool on the skin. Thanks to its hydrophilic properties, it absorbs moisture and passes it on to the overlying layers of clothing. As a result, it dries quickly and has a climate-regulating effect,” says Goral.

The unique blend of materials and knitting technology provides;

•High ballistic performance: Tailored to protect against high-speed fragments up to 200m/s

•Fragment and blast protection: Designed to prevent micro-penetrations that risk infection and soft tissue damage

•Enhanced thermal comfort: Low insulation values for better thermal regulation, particularly important for prolonged wear across climates.

Hexonia utilizes cutting-edge circular knitting machines to produce almost seamless torsos, minimizing skin irritation and increasing protective integrity.

“The absence of seams significantly enhances explosion protection, as seams are often the weakest points in a protective system,” says Goral.

Get Hands-On Experience at Milipol 2023

NFM GARM™ Ballistic Underwear will be showcased for the first time at Milipol 2023 in Paris, at the NFM booth 5D 083 between November 14th-17th.

The NFM GARM™ Ballistic Underwear will be integrated into NFM GARM™ Combat Clothing standard line and consists of a shirt and pants available with both short and long sleeves and trouser legs, fitting the unique requirements of individual operators. Available in the NFM colours Rapture Green and Raven Black.

For more information about NFM and our industry-leading products, please visit www.nfm.no.

The new Plate5 MOLLEminus Plate Carrier from Blue Force Gear is designed for use with SAPI / ESAPI plates with fully enclosed plate pockets. Made from laser cut ULTRAcomp, it is adjustable at the shoulders and at the side straps. It also incorporates laser cut PALS slots at the front and rear.

In addition to a drag handle at the rear there’s a pocket in front behind the Velcro ID field.

Please note, you size the carrier to match your SAPI / ESAPI plate size – NOT shirt, coat, or chest size.

• Medium 9.5″ wide x 12.5″ high x 1.25″ thick

For Medium SAPI / ESAPI plates

• Large 10.25″ wide x 13.25″ high x 1.25″ thick

For large SAPI / ESAPI plates

Offered in Black, Coyote, Ranger Green, and MultiCam.

www.blueforcegear.com/plate-carrier

Introducing DEFILADE’s line of public order shields: where modern police tactics meet modern innovation. Built with impact absorbing, flame resistant polycarbonate. DEFILADE’s shields are lightweight, easy to maneuver with three models to fit your operational requirements. Available shields:

Interlocking

• Can be used individually or interlocked together to form a wall or roof

• Ideal for stand-offs, provides maximum protection from projectiles and direct confrontations

• Grips are covered in rubber for improved stability and significant reduction in vibration

• Available in 4ft or 6ft lengths

Round

• Lightweight, easy to maneuver

• Ideal for quick intervention tactics, allows ability to move through a crowd

• Can easily be carried with one hand, leaving the other hand free for other equipment

Learn More: defiladeps.com/shields

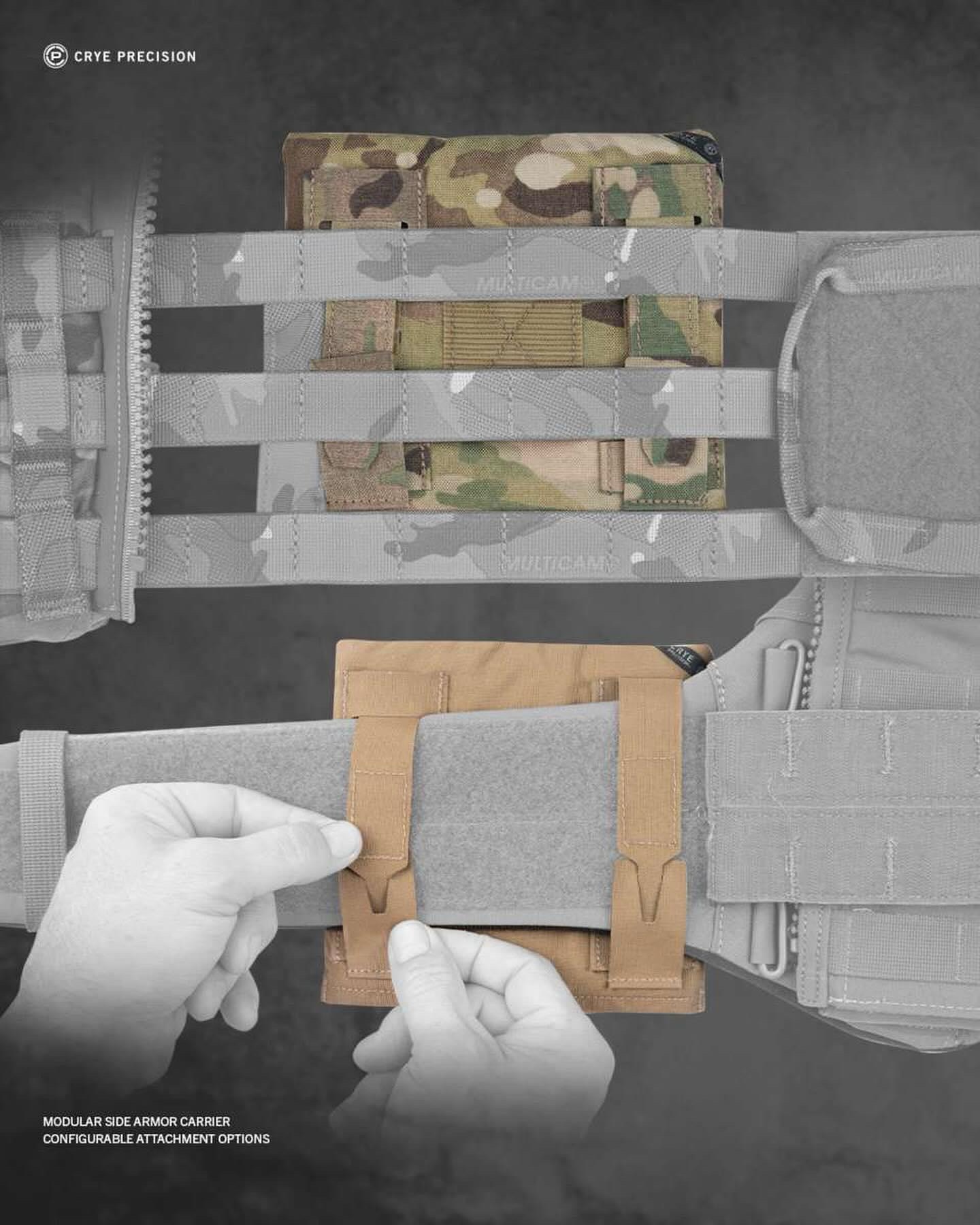

Introducing two new side armor solutions for plate carriers. The MODULAR SIDE ARMOR CARRIER (MSAC) features a revolutionary system for configurable attachment methods for various cummerbund styles. Using strong, lightweight AIRLITER® material with unique tab and slot geometry, a superior connection is provided without the potential failure that conventional snaps might have.

Interior stretch fabric accommodates soft and hard armor plates. These pouches pair with the new IIIA SIDE ARMOR INSERT, which provides Level IIIA ballistic protection in a variety of coverage areas and is designed to fit the MSAC and legacy side armor pouches.

Both items are made in the US from US materials and are available now.

www.cryeprecision.com/Modular-Side-Armor-Carrier

www.cryeprecision.com/IIIA-Side-Armor-Insert