Marine Corps Systems Command (MCSC), Portfolio Manager (PfM), Ground Combat Element Systems (GCES), Program Manager (PM) Infantry Combat Equipment (ICE) released a sources sought notice seeking information regarding industry’s capability to produce a Berry Amendment compliant lightweight hard armor plate.

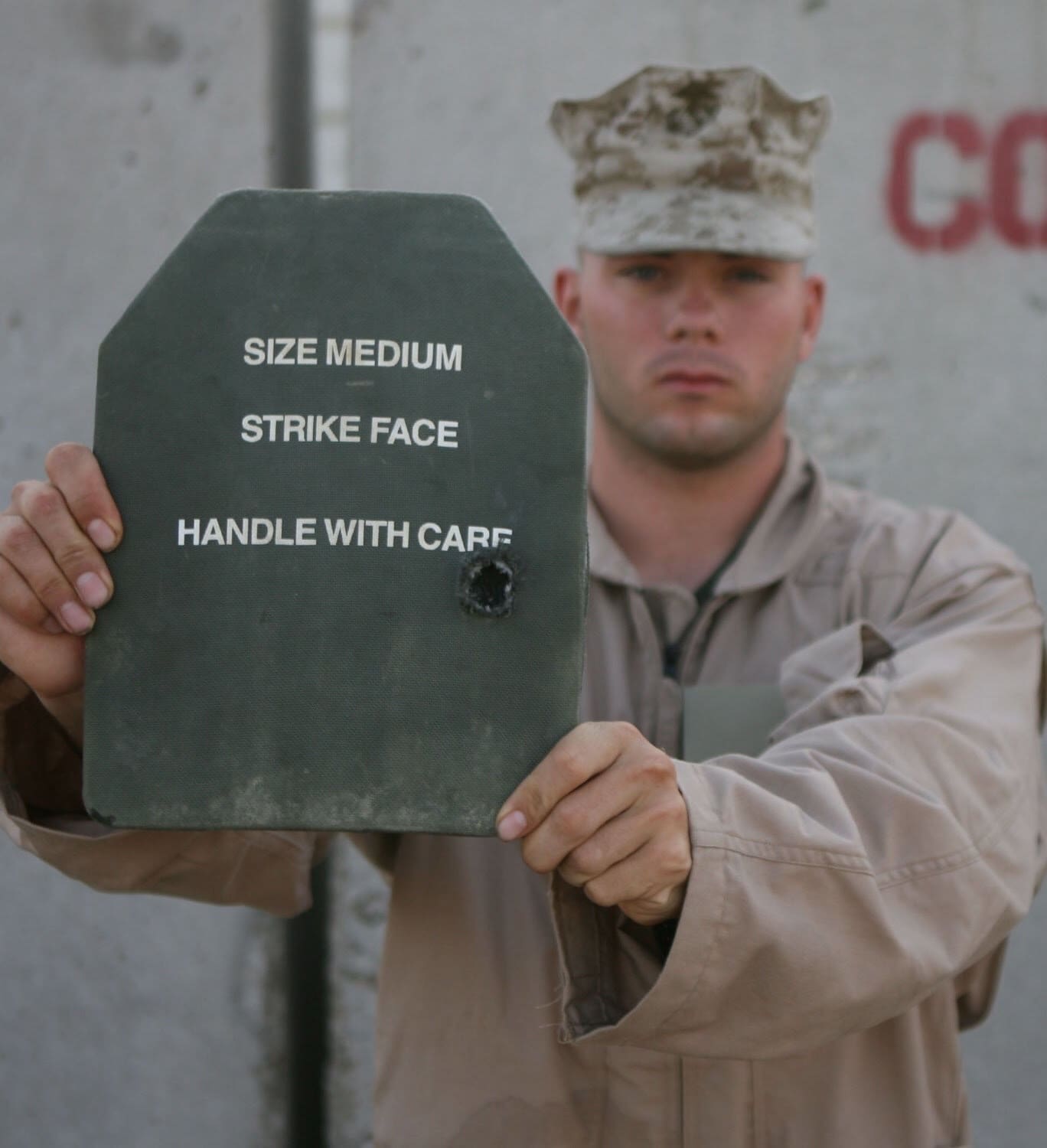

For years, the current Enhanced Small Arms Protective Insert (ESAPI) has protected Marines, and other service members from harm, but they are relatively heavy, having been designed well over a decade ago. The Marine Corps wants to leverage advancements in armor protection.

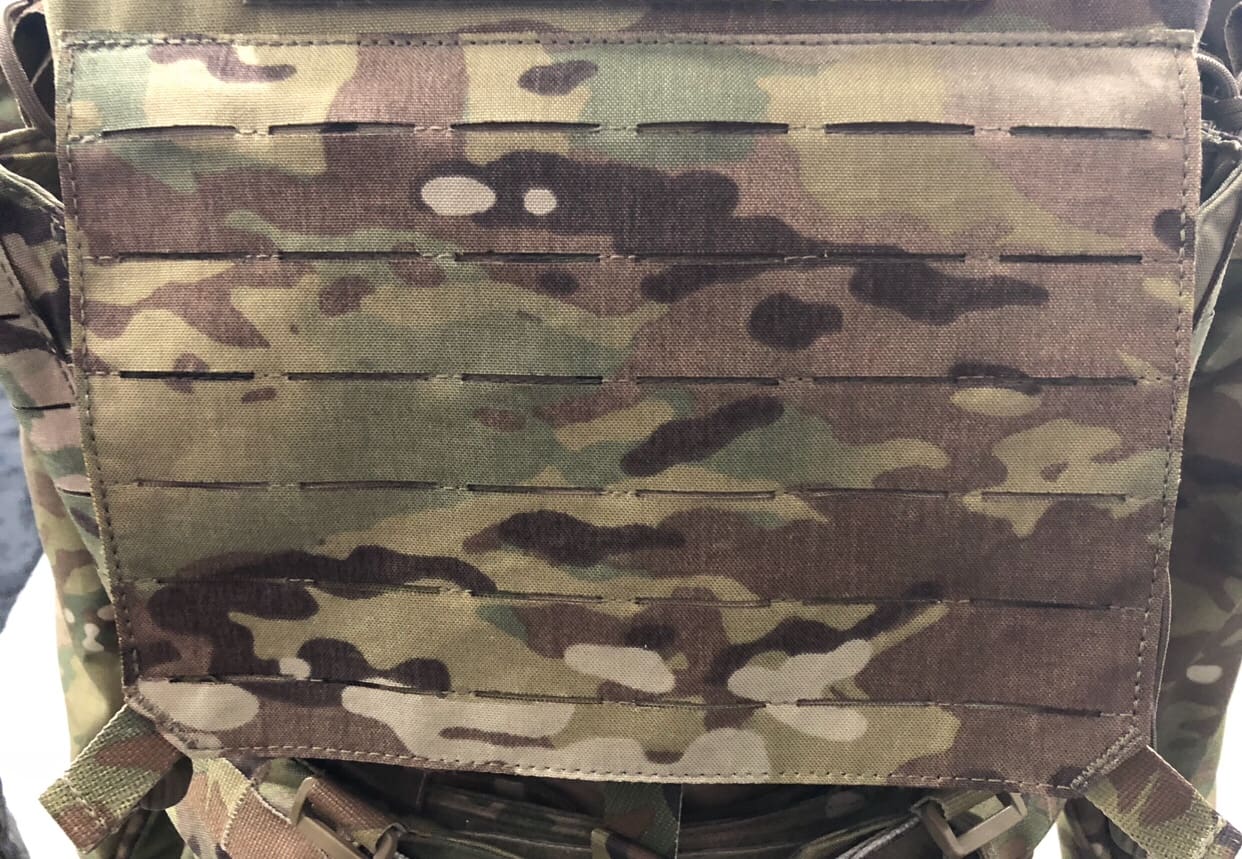

MCSC’s Marine Expeditionary Rifle Squad Team tested a selection of currently available commercial armor plates through the Marine Corps Load Effects Assessment Program course wearing all of their combat gear. MERS discovered that a lightweight hard armor plate in the range they are seeking will increase the mobility of Marines by 8 percent. It is envisioned that these new plates will be used woth the upcoming Plate Carrier Gen III, expected to begin fielding in 2019.

Over the past year, PM ICE conducted an analysis of more than 200 commercial plate designs from 38 different companies to see what type of armor is possible. However, according to the notice, there’s no actual requirement written yet, so it is important that industry respond to this Request for Information in order to inform the requirement.

According to PM ICE, the lightweight hard armor plate should:

– Provide two-shot ballistic protection from non-armor piercing rounds that are currently prevalent in counter-insurgency operations and other low intensity threat environments.

o Rounds primarily fired by sniper rifles will be tested at a velocity expected at 100m-200m standoff.

o One shot will be in the crown location at 0-degrees obliquity; the other shot will be at off-center locations at 30-degrees obliquity.

o Meet back-face deformations less than 58 mm.

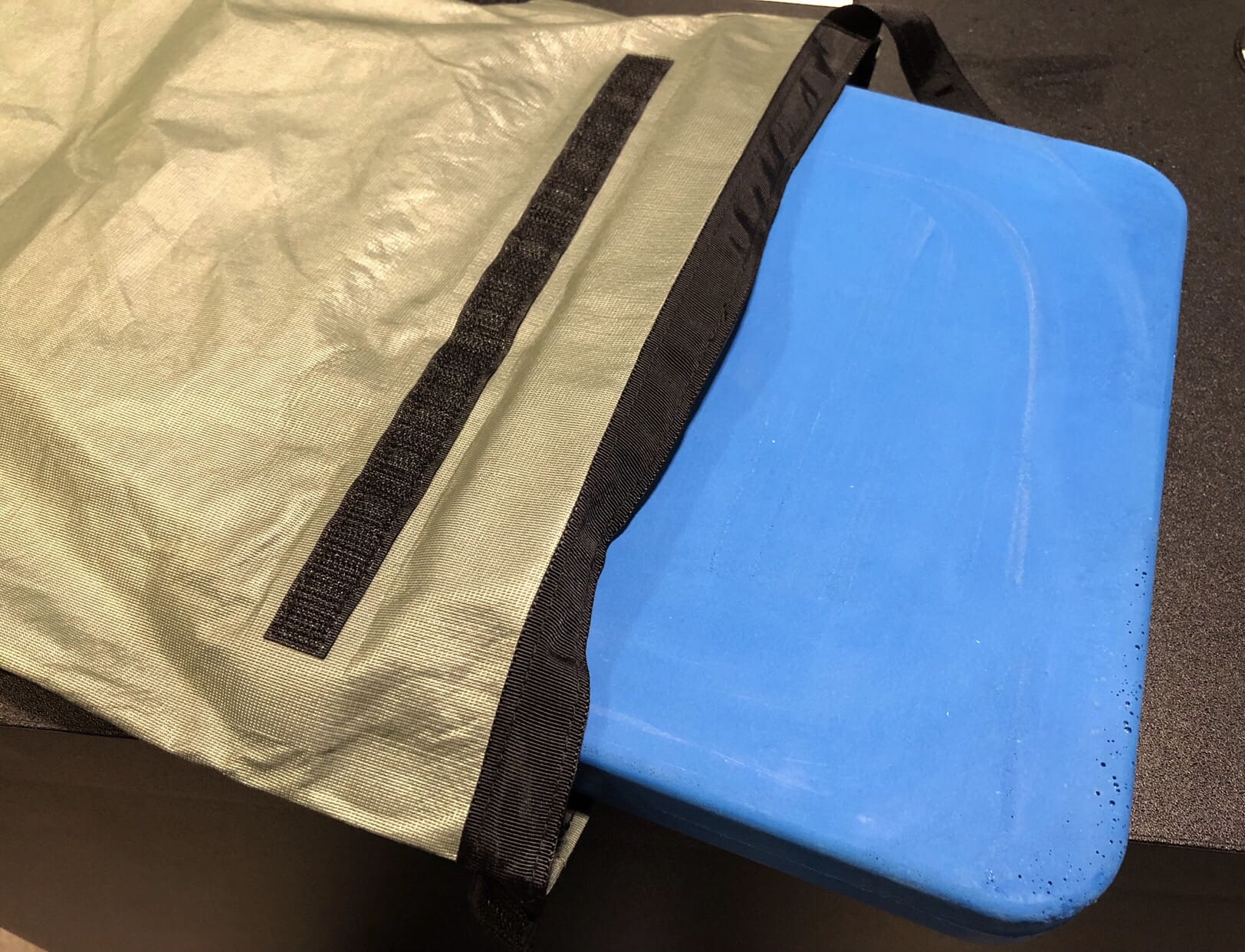

– Conform to ESAPI shape and area of coverage.

– Possess a thickness that is the same or less than current ESAPI.

– Possess an areal density of 3.75 pounds/square foot (Objective) to 5.16 pounds/square foot (Threshold).

Additionally, vendors should be able to produce a minimum of 40,000 lightweight armor plates within a year of First Article Test approval, which is expected 180 days after contract award, once the solicitation is released.

Responses are required by 7 September 2018, 12:00 p.m. Eastern Standard Time (sic).

Visit www.fbo.gov for full details.

USMC photo and video.