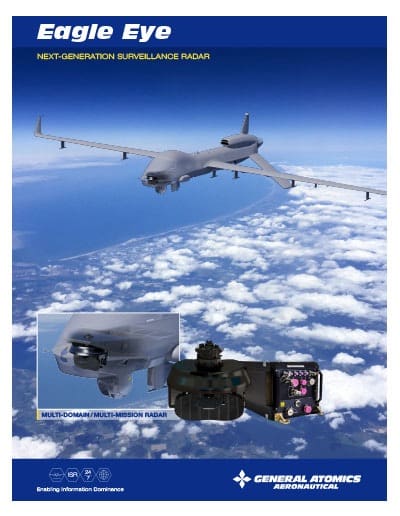

New Antenna Will Double Range and Enable Additional Radar Enhancements

SAN DIEGO – 24 April 2024 – General Atomics Aeronautical Systems, Inc. (GA-ASI) is continuing its support of EagleEye multi-mode radar development with a company investment to add an Active Electronically Scanned Array (AESA) antenna and associated software that will increase range and deliver significant mode enhancements. AESA will be a “drop-in” hardware upgrade to the existing EagleEye radar and could be an option for the new Gray Eagle 25M (GE 25M) aircraft assembly when ready.

“We expect the AESA antenna to more than double the range for EagleEye,” said Jeff Hettick, GA-ASI vice president of Agile Mission Systems. “The increased range and optimized multi-mode performance of the radar are perfectly tailored to provide deep sensing capability in Multi-Domain Operations (MDO). That will allow the aircraft to operate well outside Weapons Effects Zone of most threat systems adding a layer of survivability supporting the Stand-Off survivability with Stand-In effects of long-range sensors. This is a key component of the Gray Eagle 25M Unmanned Aircraft System being developed for the U.S. Army.”

AESA antennas replace the mechanically steered dish antennas of earlier-generation radars with a solid-state, all-electronic emitter. In addition to enhancing the radar’s performance, by replacing the motor and other components that physically move the radar dish, AESA greatly improves repairability and reliability.

As part of the EagleEye development, GA-ASI will improve target detection range using Artificial Intelligence/Machine Learning (AI/ML). GA-ASI expects to have a working lab prototype of the new AESA component by the end of this year, with plans to conduct flight tests in 2025 and operational demonstrations on GE 25M after that.

EagleEye is a multi-mode radar that builds on years of pioneering expertise by GA-ASI. Using Synthetic Aperture Radar (SAR), Eagle Eye enables operators to look in detail through clouds, smoke, dust, haze, or other conditions that might obscure a purely visual sensor. And for the first time on the Gray Eagle platform, EagleEye delivers radar-based Full Motion Video (FMV) called “Video SAR,” which enables live visual tracking of moving targets via the radar system.

The EagleEye radar performs Moving Target Indication (MTI), detects changes, builds strip maps, and yields other precise insights to analysts, commanders, and operators. With its Maritime Wide Area Search (MWAS) mode, EagleEye also provides a dedicated maritime MTI mode for tracking and targeting vessels and further supports the MDO mission set of the U.S. Army, particularly in support of the U.S. Indo-Pacific Command (INDOPACOM) mission, but also in Europe, Africa and the Middle East where there is an increased need for maritime reconnaissance, surveillance and target acquisition, which is critical to achieve information dominance and overmatch.