Archive for the ‘Camo’ Category

TRU-SPEC Launching A-TACS AU & FG Uniforms In One Month

Sunday, October 19th, 2014US Army Conducts Bookend Camo Tests at Ft Polk

Thursday, October 9th, 2014In addition to the new Operational Camouflage Pattern, the US Army has long envisioned a family of camouflage patterns with OCP serving as a general issue, transitional pattern, and special Woodland and Arid variants, color tuned for use in those environments, to support contingency operations via limited issue.

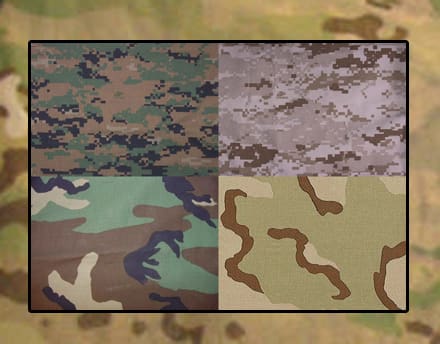

When we originally mentioned the planned bookend camouflage test in late May, we framed it as “analog vs digital” and it appears that our information was correct. SSD has obtained photos of testing being conducted at Fort Polk, Louisiana.

The testing at Ft Polk, comprised of OCP (Scorpion W2), M81 Woodland and MARPAT Woodland, is naturally geared toward the woodland environment.

While these photos only depict the MARPAT Woodland uniforms and the Soldiers are carrying UCP MOLLE and helmets, we do know that TA-50 has also been provided in the range of test patterns. You may also notice that the Soldiers in these photos are mixing it up, wearing Sand T-shirts and USMC issue Coyote (Olive Mojave) boots complete with Eagle Globe & Anchor marking. Interestingly, one Soldier has rolled his sleeves. At first it struck us odd that he had rolled his sleeves like a Marine until it dawned on us that currently serving Soldiers wouldn’t know how they would had done it in BDUs, as the Army no longer rolls its sleeves.

While we don’t have any photos of the M81 Woodland or OCP uniforms, we did score a photo of an example of the Green PALS webbing that has been paired with the OCP MOLLE. We are still unsure what this might indicate.

So far, we do no have any information on the Desert Bookend test which is said to feature OCP, 3-color Desert and MARPAT Desert.

MMI Textiles And Hyde Definition Create A Partnership For Production And Distribution Of The PenCott™ Brand Of Camouflage For Domestic And International Military And Commercial Markets

Tuesday, October 7th, 2014WESTLAKE, OHIO, USA, OCTOBER 7, 2014 – MMI Textiles introduces Hyde Definition’s PenCott™ family of patterns into its strong portfolio of military textile products. The PenCott™ inventory will initially consist of the BadLands™, GreenZone™, SandStorm™ and SnowDrift™ patterns on 500D Cordura, Nylon-Cotton Ripstop, and 50D Polyester fabrics – all printed and finished to meet US milspec nIR standards. Future production will also expand to include Asia for delivery to our customers who manufacture their end products in the Far East. Additional fabric and fabric-based substrates will be added to the portfolio as well – some of which will also leverage new printing technologies.

Increased availability of PenCott™ patterns, with commitment from the MMI Team

MMI has always had a strong commitment to the US armed forces, and many of our international customers also seek quality products that have been manufactured to US standards. We have over 30 years of experience in the military market producing cotton, nylon, polyester and blended fabrics. The PenCott™ family of camouflage patterns greatly enhances our existing product offering and we are excited to have this opportunity to increase sales and marketing efforts for this newly created partnership. For further information about the PenCott™ patterns, please visit www.HydeDefinition.com and/or the PenCott™ Facebook page at: www.Facebook.com/PenCottcamouflage.

PenCott™ – Mission Critical Camouflage: the science behind the solution

The development of the PenCott™ pattern began in 2005 as a result of Dom Hyde noting that virtually all current-issue military camouflage patterns for clothing were ineffective in many environments and missions in a post 9/11 world. Dom’s decades of studying and experimenting with thousands of camouflage designs and the direct result of several years of independent research and development has gone into the creation of PenCott™.

The 360° pattern geometry – with the inclusion of large, medium and small fractal shapes – makes the PenCott™ patterns effective at close, mid and long range; and because of its non-linear orientation, the full effectiveness of the pattern is retained whether the wearer is standing, kneeling or prone.

Polish MultiCam “Inspired” Variants

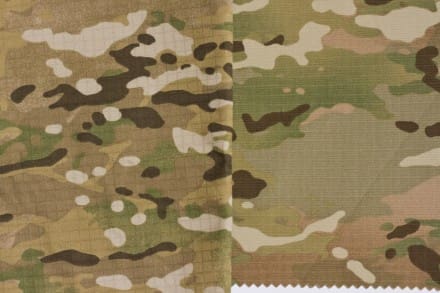

Wednesday, October 1st, 2014According to an industry source, for the past few years Polish Special Forces have been utilizing a MultiCam knockoff pattern called “Suez”. “Suez” is very similar to MultiCam, and is missing only one color when compared to the original pattern. It consists of dark brown, olive green, light olive, beige, and tan on a sandy background. It is printed by the Polish fabric printing company Andropol, and has since also been introduced to other services such as the BOR – Polish Secret Service. Recently, at the MSPO trade show, Andropol introduced a green coloration as a proposal of a new pattern for the Polish Border Guard.

In the image above, you can see “Suez” on the left, printed on 50/50 PolyCotton fabric, with MultiCam on the right printed on 50/50 NyCo. The below image shows a swath of “Suez” printed on 50/50 PolyCotton.

As you can see, “Suez” is very similar to commercial MultiCam in composition.

Some ODG Lupus Eye Candy

Sunday, September 28th, 2014This rifle is equipped with a 14.5″ Rainier Arms .300 Upper with an OSS Bannar Flash Hiding Muzzle Brake mated to an AAC lower. The rifle was dipped in ODG’s Lupus pattern and outfitted with a VTAC Sling.

Polish SOF Using A-TACS FG

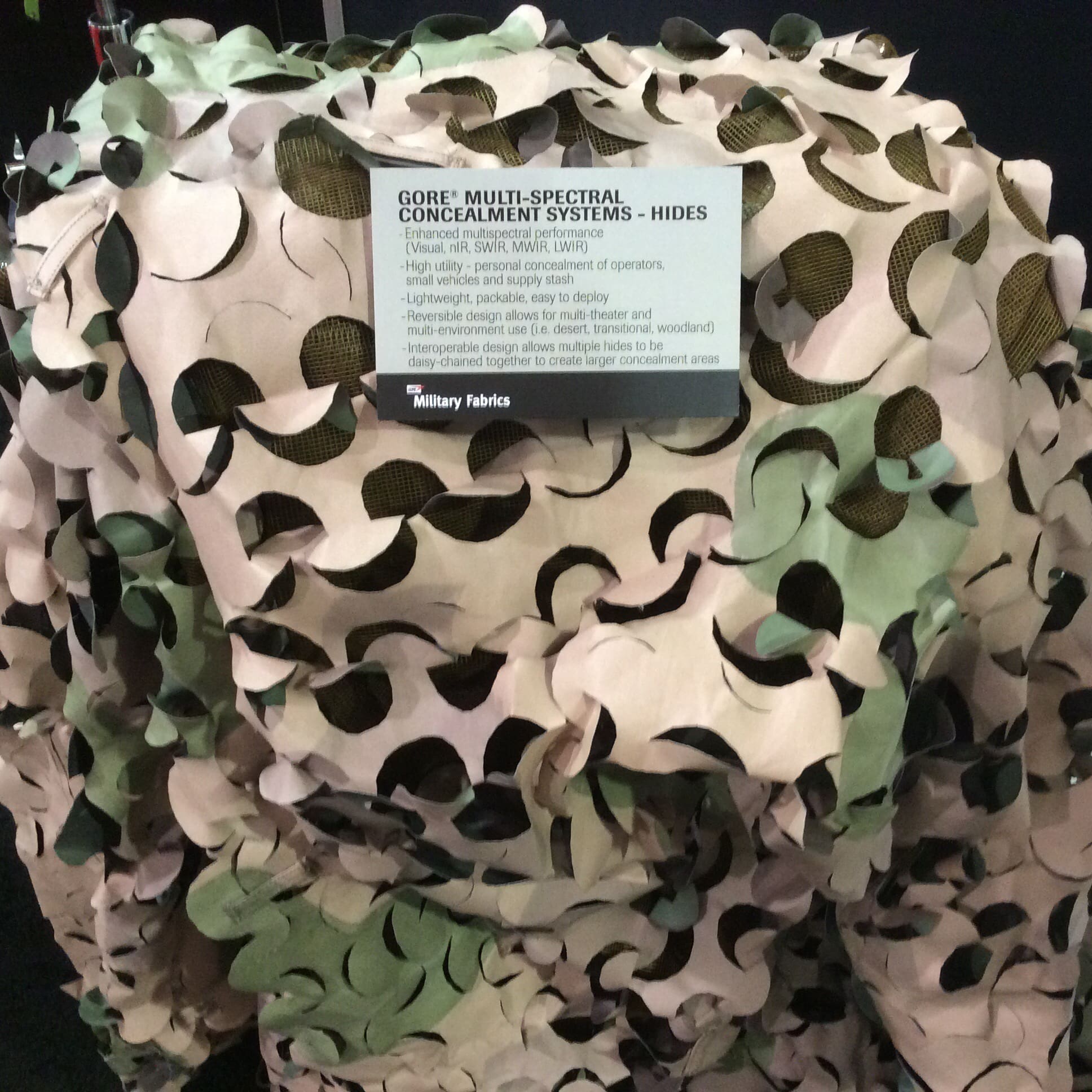

Friday, September 26th, 2014MDM – WL Gore & Associates – MultiSpectral Concealment Systems

Wednesday, September 24th, 2014WL Gore is offering a new application of the MultiSpectral concealment technology used in the Turkey Suit we showed you last year. Now, they are offering hide systems that can be used to conceal a variety of emplacements and systems such as fighting positions and vehicles.

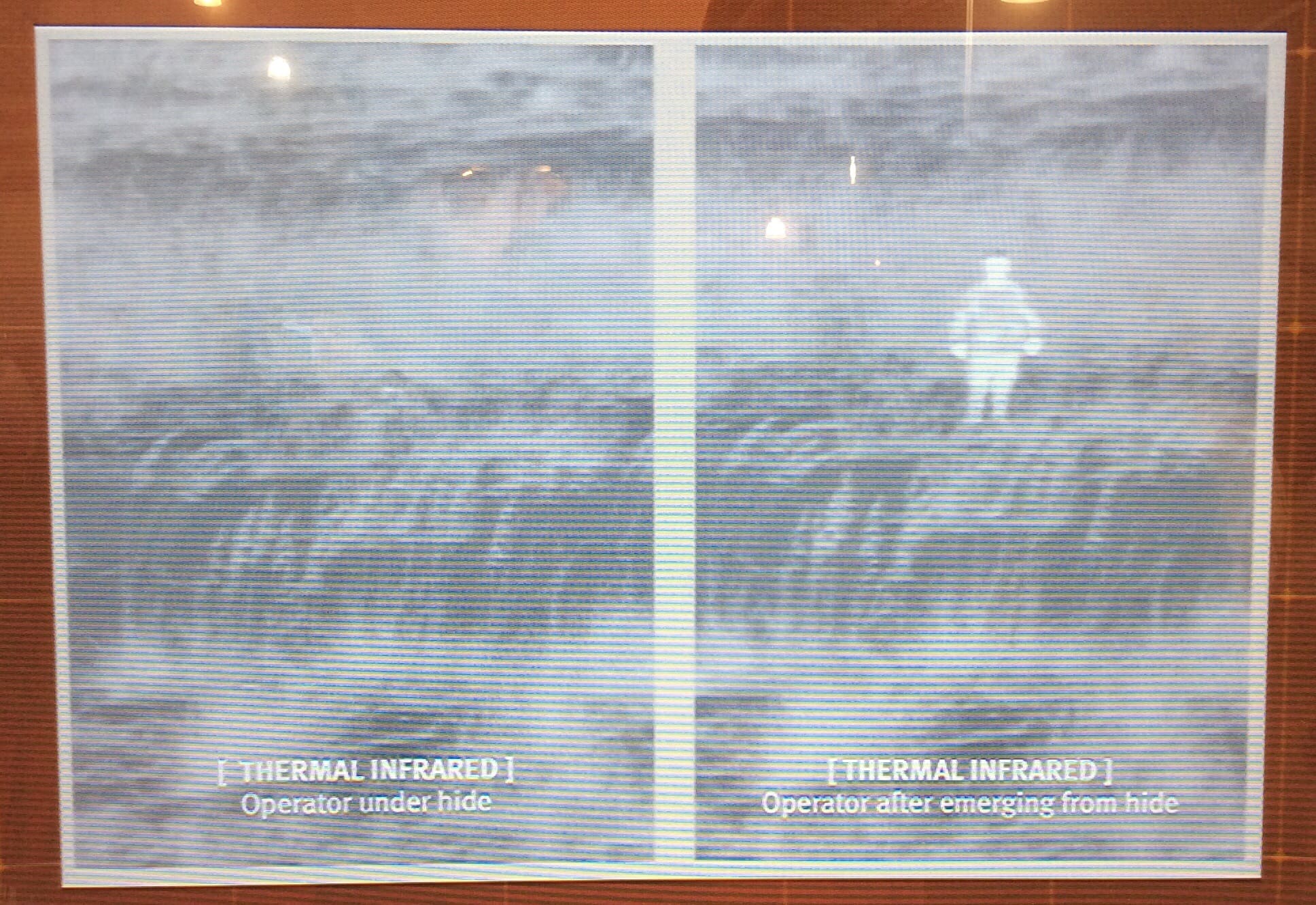

As you can see, the technology does a great job of concealing the user under thermal sensors (LWIR above) but it also offers visual, niR, SWIR and MWIR.

The hide systems are reversible and can be used for a variety of environments such as desert, woodland or transitional. Additionally, they can be daisy chained together to create a variety of configurations.

www.multispectralconcealment.com

Crye Precision’s 2001 Scorpion Development Contract Calls Into Question Army Claims Of “Appropriate Rights To Use” New OCP Variant

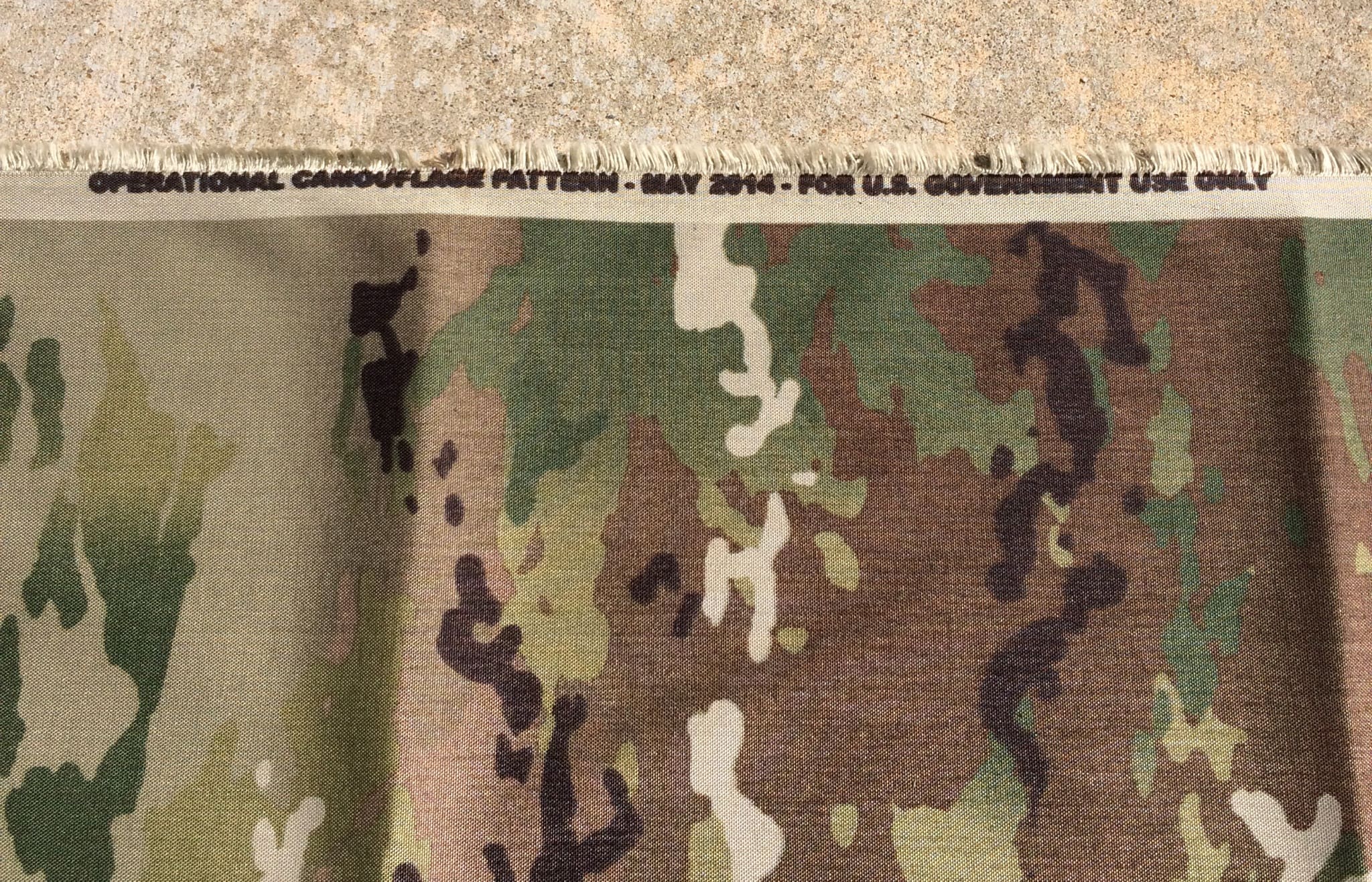

Monday, September 22nd, 2014Many have questioned the US Army’s right to use a recently announced camouflage pattern, so a few weeks ago we decided to put it to bed and asked the Army about it. They offered us a rather curt, but confident, answer. But then DLA began a quest to fund a new printer that didn’t pay commercial printing royalties to Crye Precision for Scorpion. So last week, we ran a story regarding the US Army’s statement that they had “Appropriate rights to use the Operational Camouflage Pattern” and, in the process, exposed a major controversy that had arisen over printing royalties for OCP.

The US Army uses the name Operational Camouflage Pattern to refer to the Scorpion W2 camouflage pattern which is a 2010 modification of the so-called Scorpion pattern originally introduced by Crye Precision in 2001 and patented in 2004. What is at question, is whether or not the Army can use the pattern, royalty-free.

We know that Crye filed for, and was granted, a patent for this camouflage by the US Patent and Trademark Office, Camouflage Pattern Applied to Substrate US D487,848 S, March 30, 2004. We also know that not long after the patent was granted, the Army asked the PTO to insert the following addendum into the patent:

After claim, insert the following:

–Statement as to rights to inventions made under federally sponsored research and development.

The U.S. Government has a paid-up license in this invention and the right in limited circumstances to require the patent owner to license others on reasonable terms as provided for by the terms of contract No. DAAD16-01-C-0061 awarded by the US Army Robert Morris Acquisition Natick Contracting Division of the United States Department of Defense.–

From this, we surmised that the US Army’s assertion of appropriate rights is based on the funding of the Scorpion project via contract (DAAD16-01-C-0061) in September of 2001. This 13 year-old contract has remained the missing piece to this puzzle. Does this contract, in fact, prefer rights to the camouflage to the US Army?

(more…)