Ask anyone at Crye Precision and they’ll tell you they’re proud to be based in New York City and prouder still to be headquartered at the famous Brooklyn Navy Yard.

Just like the Brooklyn Navy Yard built ships to help win World War Two, the current tenants of the facility have risen to the challenge of facing this nation’s newest threat, COVID-19.

Mayor Bill de Blasio recently put out the call to New York businesses to help with the medical response to the pandemic, which is hitting the Big Apple hard. A natural fit to this response are those engaged in the textile business.

Although Manhattan is an island, the domestic textile industry isn’t. It stretches across this great land and Crye Precision was able to call upon them to provide materials critical to this response. As you’ll see below, the list is long.

In fact, it’s the American textile industrial base which has made this project, as well as similar responses across the country, possible. If it weren’t for the Berry Amendment and its mandate for American made materials and finished goods, our nation would be at the mercy of other countries. Hopefully, this is a wake up call and we see more investment in such capabilities, so that when push comes to shove, America can continue to stand on her own two feet.

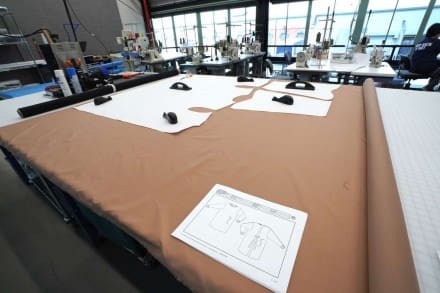

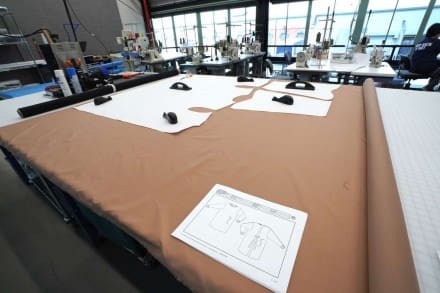

In response to the Mayor’s call, Crye and others have begun manufacturing medical gowns for area hospitals.

This hasn’t been easy. Not all of their team is back to work and Crye remains committed to fulfilling military and law enforcement contracts, in addition to their COVID-19 response efforts.

Earlier this week, Mayor de Blasio thanked the members of the Brooklyn Navy Yard Emergency Response for their efforts while making a visit to the various facilities.

Crye Precision Executive Director Gregg Thompson put out this statement on Instagram yesterday:

The COVID-19 pandemic has affected us all. For the past month at Crye Precision, we have teamed up with the @bklynnavyyard & @lafayette148ny to help answer the City’s call for medial PPE.

This week alone, 2.5 million surgical gowns will be used across the City in hospitals and nursing homes. Our combined efforts will hopefully alleviate part of this dire need for medical PPE by manufacturing thousands of protective hospital gowns to supply the City’s health care workers. Our goal is to create 320,000 reusable surgical gowns by the end of April.

This endeavor has been made possible by our U.S. fabric supply chain partners that we have relied on for years to make our military and law enforcement products. Suppliers like @mmitextiles, @tweave_llc , @brookwoodcos , @american_e_thred, @narroflex, @murraysfabrics Fabrics and @VastestLabs have been vital to sourcing the necessary raw materials to make these medical gowns.

We are honored to partner with companies like Lafayette 148, Stitch NYC, @kaiminofficial , @kingbridgenyc , Kustin Paul, NY Ortho, Accurate Knitting, Martin Greenfiled Clothiers, Skillset, 1947LLC, Honeywell, Tencate, Lion Apparel, Matinal Safety Apparel, Milliken, Invista, @textilenetwork, Inkcups, UFP, Flextech, Mikan and the rest of the Brooklyn Navy Yard Emergency Response cooperative during this unprecedented time, bringing the highest ingenuity to work toward a common goal to help workers on the frontline of the crisis.