Company Creates More than 50 New Jobs in Ohio and Prioritizes the Hiring of Veterans

U.S. Representative Warren Davidson to Tour Facility as Congress Considers Bipartisan Legislation in Support of More Domestic Manufacturing

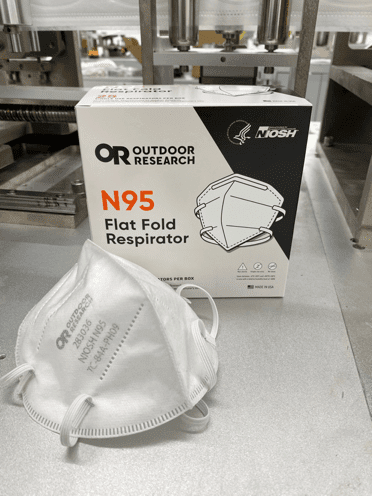

New York, NY – October 13, 2020 –The Chargeurs Group today announced a significant investment to expand the company’s U.S. manufacturing footprint to reshore personal protective equipment (PPE) production. The project will support Chargeurs’ newest division, U.S.-based Lainiere Health & Wellness, which will oversee the distribution, marketing and sales of all U.S.-manufactured PPE, including consumer-grade and medical-grade three-ply masks as well as 95-level respirator masks. The company will welcome U.S. Representative Warren Davidson at its Troy, Ohio, facility, Novacel Inc., which is creating more than 50 new jobs in the state and prioritizing the hiring of military veterans.

“Chargeurs is highly committed to developing new industrial capacity in the U.S. and to contributing to the country’s ability to manufacture PPE domestically,” said Michaël Fribourg, Chairman and CEO of Chargeurs Group. “We are grateful to all of our U.S. teams for their own longstanding commitment to success and we will continue to invest in our American manufacturing capability in the coming years.”

Chargeurs’ Ohio manufacturing facility is in a district represented by Representative Warren Davidson, a former Army Ranger who spent 15 years owning and operating manufacturing companies in Ohio. Congressman Warren continues to champion Ohio manufacturing and his tour of Chargeurs’ facility in Troy follows the introduction of bipartisan legislation by Ohio Senator Rob Portman and Michigan Senator Gary Peters that would incentivize more American companies to reshore production of PPE, reducing the U.S.’s reliance on foreign-made supplies. Should it be signed into law, the Make PPE in America Act would require the federal government to issue long-term contracts to companies to produce PPE in the U.S. The law would help provide manufacturers with the certainty they need to justify an investment in U.S. production.

“I love seeing this growth in manufacturing in southwest Ohio,” said Congressman Davidson, who represents Ohio’s 8th District. “As we’ve seen this year, keeping production inside the U.S. isn’t just important for the economy, it is critical to our national security. As a former manufacturer and Army Ranger, I’m also glad to see that hiring veterans is a priority for businesses. This is a win-win for all involved.”

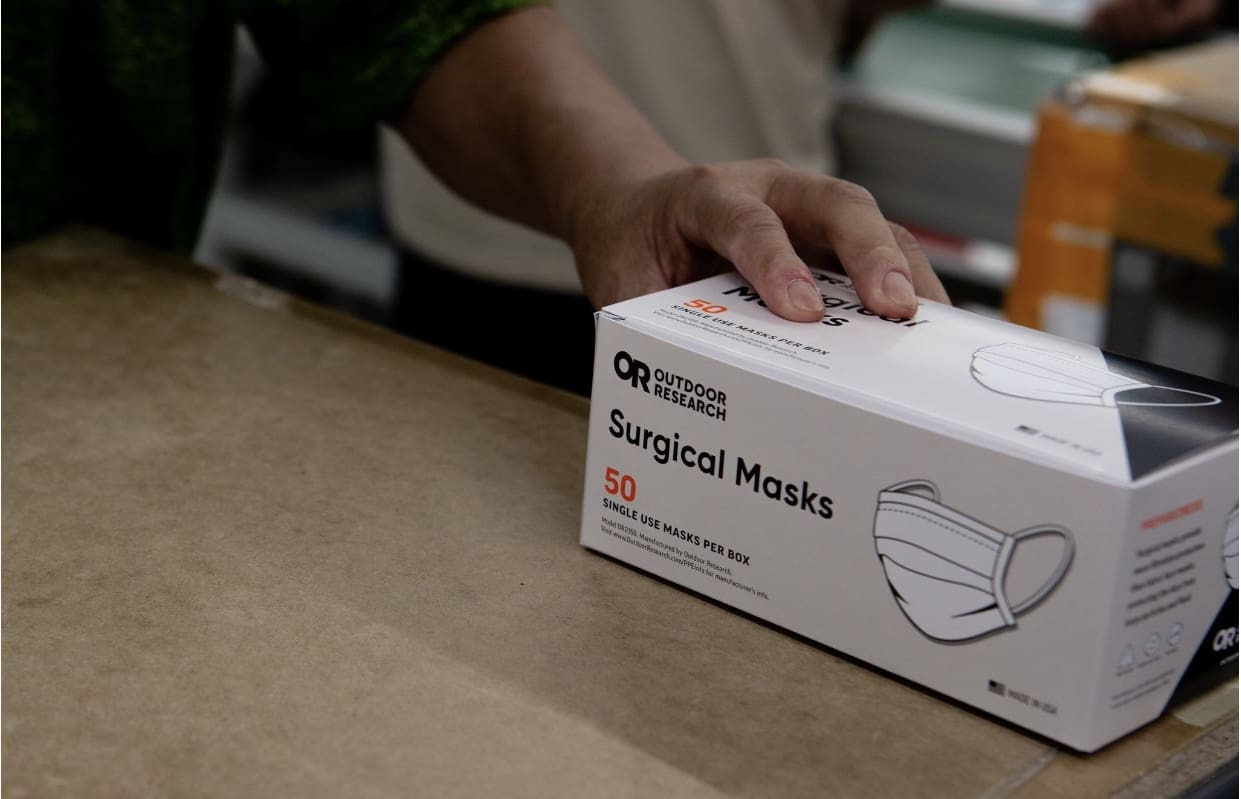

When the COVID-19 pandemic revealed the risk of relying on foreign countries for PPE, Chargeurs began retrofitting part of its Troy, Ohio, manufacturing facility to help alleviate the domestic shortage of this critical equipment. The facility has begun with lines that can produce up to 2.5 million masks a month and will increase its production capacity in the coming months. Chargeurs also aims to produce Berry-compliant masks that meet the requirements of US military and government contracts by the end of the year.

“Chargeurs has invested significant capital in retooling our Ohio factory to reshore production of PPE to America,” said Angela Chan, CEO and President of Chargeurs*PCC Fashion Technologies. “We have been supplying raw materials to the PPE market for years, so it made perfect sense to pivot to manufacturing these products in the USA, especially given the severe shortages of this equipment our country has seen since the start of the pandemic.”

“We could not be prouder to leverage our technical expertise in materials and textiles to help fill the urgent need for these supplies and to bring jobs—including jobs for veterans—back to Ohio,” added Laurent Derolez, CEO of Chargeurs Protective Films and President of Novacel Inc.

“Reshoring production of PPE items like masks is critical to prevent a repeat of the supply chain breakdown that caused major shortages earlier this year,” said Mark McCormick, Manufacturing Growth Specialist at FASTLANE, West Central Ohio’s Manufacturing Extension Partnership, which is located within the University of Dayton Research Institute. “The investment that Chargeurs is making in Troy will help to ensure that Americans have the PPE they need while also creating additional jobs for our region.”

The Troy Facility Is Just One Example of Chargeurs’ Commitment to Made in the USA Manufacturing

Chargeurs is a France-based, family-owned diversified group operating as a worldwide leader in various businesses, including technical and performance textiles for the apparel and fashion industry, surface protection solutions, and business services and fabrication for the museum, cultural and entertainment sectors. Under Michaël Fribourg’s leadership, Chargeurs has been investing in the U.S. since 2015 to support a strong Made in the USA strategy.

In addition to its investment in the Novacel Inc. facility in Ohio (formerly known as Troy Laminating & Coating), Chargeurs has invested in manufacturing technologies in a number of its other U.S. facilities, including Main Tape Company Inc. in New Jersey, Walco Inc. in California, Lainiere de Picardie Inc. in Pennsylvania, Design & Production Incorporated in Virginia, and Chargeurs Wool USA Inc. in South Carolina.