FORT MEADE, Md. — In the distant future, teams of Soldiers equipped with high-powered exoskeletons disembark a series of autonomous personnel carriers outside the enemy’s position. Overhead, a small fleet of drones scans the engagement area, giving each Soldier a real-time view of the battlefield through their heads-up display.

As each team moves into position, they hear a series of explosions on the other side of the enemy base. From over 2,000 meters away, the Army’s high-energy precision fires systems have just disabled the enemy’s anti-access and area-denial capabilities.

At the same time, teams of Soldiers use their exoskeleton suits to leap over the perimeter wall to engage the enemy and secure the compound.

This is one scenario of a future operating environment. In reality, it is nearly impossible to predict how the Army will operate and fight in a distant future, said Matt Santaspirt, an Army Futures Command intelligence representative.

To guide the Army in the right direction, the U.S. Army Training and Doctrine Command’s Mad Scientist team functions like a scout on the battlefield, always looking ahead and evaluating ideas to help build the force, he said.

Nested within both Army Futures and Training and Doctrine Commands, the MadSci initiative was created to address opportunities and challenges in the Army’s near-, mid-, and far-term future, said Allison Winer, the team’s deputy director of engagement.

The goal is to maximize the Army’s limited resources and help Soldiers fight and win in a futuristic operational environment, she added.

“The Army only knows what it knows; and [the Army] always talks to itself,” Santaspirt said. “We want to break out of that echo chamber.”

“We are harnessing the intellect of the nation to describe the art of the possible,” he added. “We know that you can’t predict the future, but we’re trying to say, ‘Here is a range of possibilities.’ [The goal] is to be less wrong than our adversary.”

To accomplish this goal, the MadSci team compiles information from a wide range of sources, in support of Army senior leaders’ priorities, Santaspirt said.

These sources include traditional mediums: academia, industry, think tanks, labs, reports, and white papers; to the more nontraditional platforms: crowdsourcing, social media, science fiction, and cinema, to name a few.

Beyond the collection of materials, the MadSci team often organizes themed conferences, bringing communities together to address key Army topics. For example, the team recently conducted the Mad Scientist Disruption and the Future Operational Environment Conference in Austin, Texas.

During the conference, presenters addressed robotics, artificial intelligence and autonomy, the future of space, planetary habitability, and the legal and ethical dilemmas surrounding how these disruptive technologies will impact the future of warfare, specifically in the land and space domains, according to MadSci officials.

“We had somebody come in and talk about robotics and how we can use them in an austere environment,” Santaspirt said, adding there were specific examples of robotics used in Fukushima, Japan.

“The approach is to bring together experts … so we can refine those key ideas, and disrupt [the Army’s] assumptions,” he said.

A week after the event, the team posted some key takeaways from the conference on the Mad Scientist Blog. The MadSci blog and other social media platforms are often used as a crowdsourcing tool to help poll an audience or generate conversation about key Army topics, Winer said.

Some of the conference findings included: a need to set left and right boundaries for artificial intelligence and autonomy, increased crowding of assets in space will cause operational challenges, and fake news coupled with hyper-connectivity is changing the nature of information warfare.

Additionally, the MadSci team organizes science fiction writing competitions to help determine possible futures for crucial Army programs, Winer said. For years, science fiction has depicted worlds that are both logically possible, but functionally different than current society.

“Science fiction is used as a kind of forecasting to see what possible futures might look like,” she said. “Aside from being just plain-on cool, it gives the Army a way to use storytelling, historical analysis, and outsourcing to write about the realm of the possible. And it is an effective tool for a lot of businesses and other leaders in industry to try.”

Through their research and continual online engagements, the MadSci team creates a range of possibilities, then later presents their findings to Army senior leaders and key decision makers, Santaspirt said.

“It is a different way of thinking,” Santaspirt said. “If [the Army] can get that out there and start meeting the right people, make certain decisions or investments, or get people thinking in a different way … you might see what we’ve discovered — as it comes to light down the road.”

Mad Scientist Initiative Website

Mad Scientist Initiative videos

By Devon L. Suits, Army News Service

Photos by Peggy Frierson & Mad Science Initiative

1) The Army is having an “Own the Night” moment. It has the opportunity to gain a competitive advantage over adversaries who have spent large amounts of capital and effort on gaining overmatch in niche areas like Anti Access/Area Denial (A2/AD) and anti-tank capabilities. The Army can “Own Unmanned and Autonomous Warfare.” There is a sweet spot in

1) The Army is having an “Own the Night” moment. It has the opportunity to gain a competitive advantage over adversaries who have spent large amounts of capital and effort on gaining overmatch in niche areas like Anti Access/Area Denial (A2/AD) and anti-tank capabilities. The Army can “Own Unmanned and Autonomous Warfare.” There is a sweet spot in  2) Setting norms in AI/autonomy may accelerate development as researchers and programmers have defined left and right boundaries. Currently, uncertainty and lack of clarity are causing delays and trepidation in their development. If the DoD establishes the absolute boundaries of its AI and autonomy policies, it can streamline R&D, S&T, and acquisition / modernization. However, setting firm left and right boundaries does present some risk — with reduced development and asymmetry in adversarial AI development and implementation.

2) Setting norms in AI/autonomy may accelerate development as researchers and programmers have defined left and right boundaries. Currently, uncertainty and lack of clarity are causing delays and trepidation in their development. If the DoD establishes the absolute boundaries of its AI and autonomy policies, it can streamline R&D, S&T, and acquisition / modernization. However, setting firm left and right boundaries does present some risk — with reduced development and asymmetry in adversarial AI development and implementation. 3) Artificial Intelligence and Trust. Successfully incorporating AI into Army formations to gain and maintain competitive advantage over adversaries in an increasingly contested OE will require bridging the gap between AI and humans by

3) Artificial Intelligence and Trust. Successfully incorporating AI into Army formations to gain and maintain competitive advantage over adversaries in an increasingly contested OE will require bridging the gap between AI and humans by  4) The Increased Crowding of Space will Create Operational Challenges for the US Army: A maneuver Brigade Combat Team has over 2,500 pieces of equipment dependent on

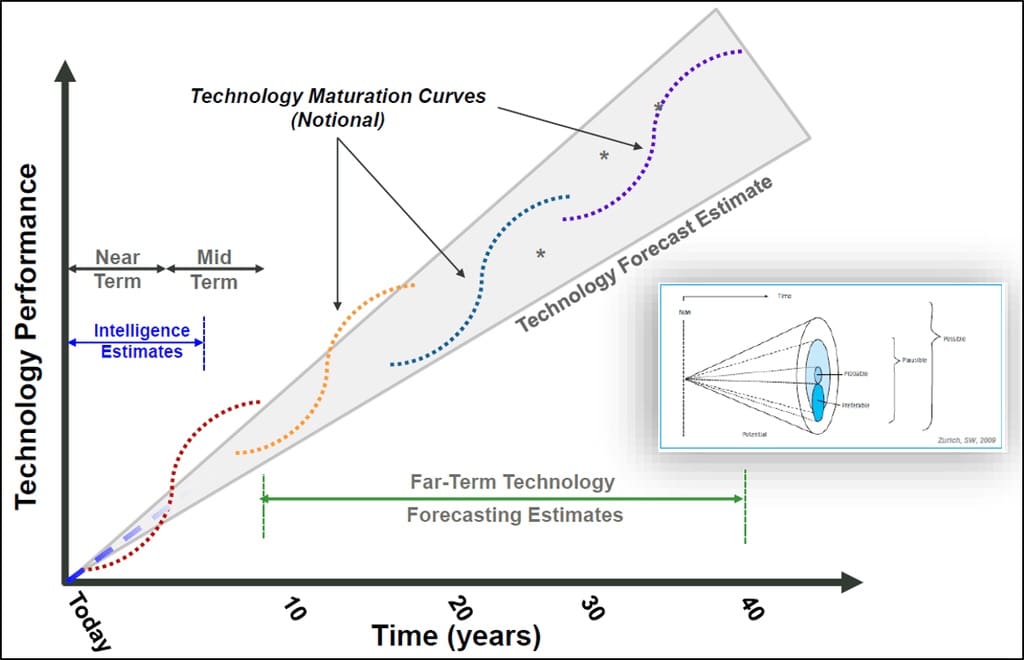

4) The Increased Crowding of Space will Create Operational Challenges for the US Army: A maneuver Brigade Combat Team has over 2,500 pieces of equipment dependent on  5) Technology forecasting helps us understand what is probable, but with proper planning based on this insight, we can begin to determine what is necessary and

5) Technology forecasting helps us understand what is probable, but with proper planning based on this insight, we can begin to determine what is necessary and  6) Scaling up technology in the military may necessitate a change to the ways in which they are developed. The rapidity of technological advancement may force development of whole systems – counter to current acquisition processes – rather than individual technology segments.

6) Scaling up technology in the military may necessitate a change to the ways in which they are developed. The rapidity of technological advancement may force development of whole systems – counter to current acquisition processes – rather than individual technology segments. 7) Disposable versus Exquisite: Current thinking espouses technologically advanced and expensive weapons platforms over disposable ones, which brings with it an aversion to employ these exquisite platforms in contested domains and an inability to rapidly reconstitute them. In large-scale ground combat operations with a peer competitor, the ability to reconstitute will be imperative. The Army (and larger DoD) may need to shift away from large and expensive systems to cheap, scalable, and potentially even disposable unmanned systems.

7) Disposable versus Exquisite: Current thinking espouses technologically advanced and expensive weapons platforms over disposable ones, which brings with it an aversion to employ these exquisite platforms in contested domains and an inability to rapidly reconstitute them. In large-scale ground combat operations with a peer competitor, the ability to reconstitute will be imperative. The Army (and larger DoD) may need to shift away from large and expensive systems to cheap, scalable, and potentially even disposable unmanned systems. 8) Leveraging Allies in Fielding Future Technology: International Joint projects with our allies have benefits in cost-sharing, interoperability, and fostering cultural diversity in the development of crucial, complex technologies. Just as NASA collaborated with a variety of international partners for its Europa Clipper mission, so to could the U.S. Army when it comes to AI and autonomous warfare, as well as quantum information sciences, hypersonics, and directed energy weapons.

8) Leveraging Allies in Fielding Future Technology: International Joint projects with our allies have benefits in cost-sharing, interoperability, and fostering cultural diversity in the development of crucial, complex technologies. Just as NASA collaborated with a variety of international partners for its Europa Clipper mission, so to could the U.S. Army when it comes to AI and autonomous warfare, as well as quantum information sciences, hypersonics, and directed energy weapons. 9) The Army should expand its learning beyond past combat actions and open

9) The Army should expand its learning beyond past combat actions and open 10) The Changing Nature of Information Warfare: The prevalent and growing presence of fake news, data, and information, coupled with

10) The Changing Nature of Information Warfare: The prevalent and growing presence of fake news, data, and information, coupled with