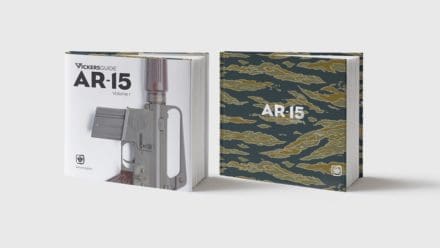

Whether or not you missed out on the first edition of Vickers Guide: AR-15 (Volume 1), you’ll want to pick up this new, expanded second edition.

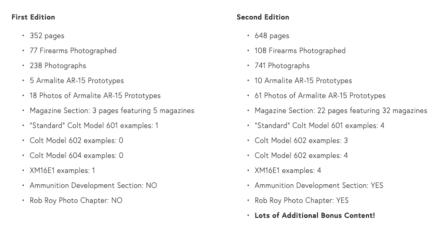

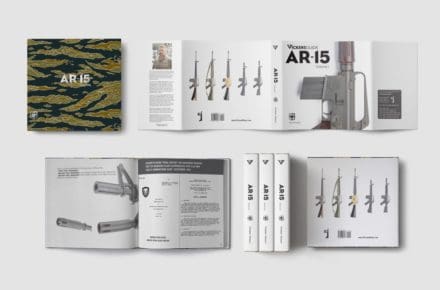

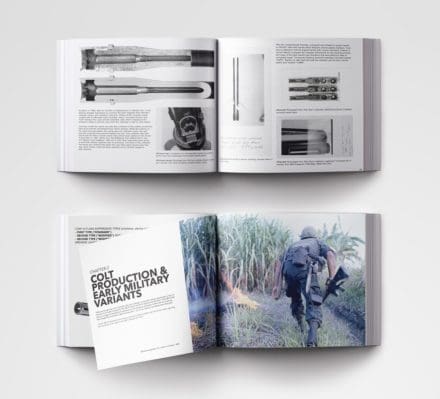

Rather than just reprint the premier edition, they’ve added 300 pages of content, making it almost twice the size of all other Vickers Guide books, with 70% more firearms and three times the photographs.

They also also added lots of new commentary. The team brought in Chris Bartocci and Daniel Watters as co-authors for their insight and expertise. Additionally, Col. Lutz contributed lots of photos and commentary on the A2 program; Alex Young assisted with a massive 22 page section on the evolution of the AR-15 magazine and he also contributed photos from the estate of Colt Engineer Rob Roy; Curtis Debord advised on the “CAR-15” variants; and John Meyer, MACV-SOG veteran, contributed images and commentary on experiences in Southeast Asia with the XM177E2.

Don’t miss this. Signed and personalized versions are available.

Shipping October 2020, pre-order yours now at www.vickersguide.com/ar15-2ed.