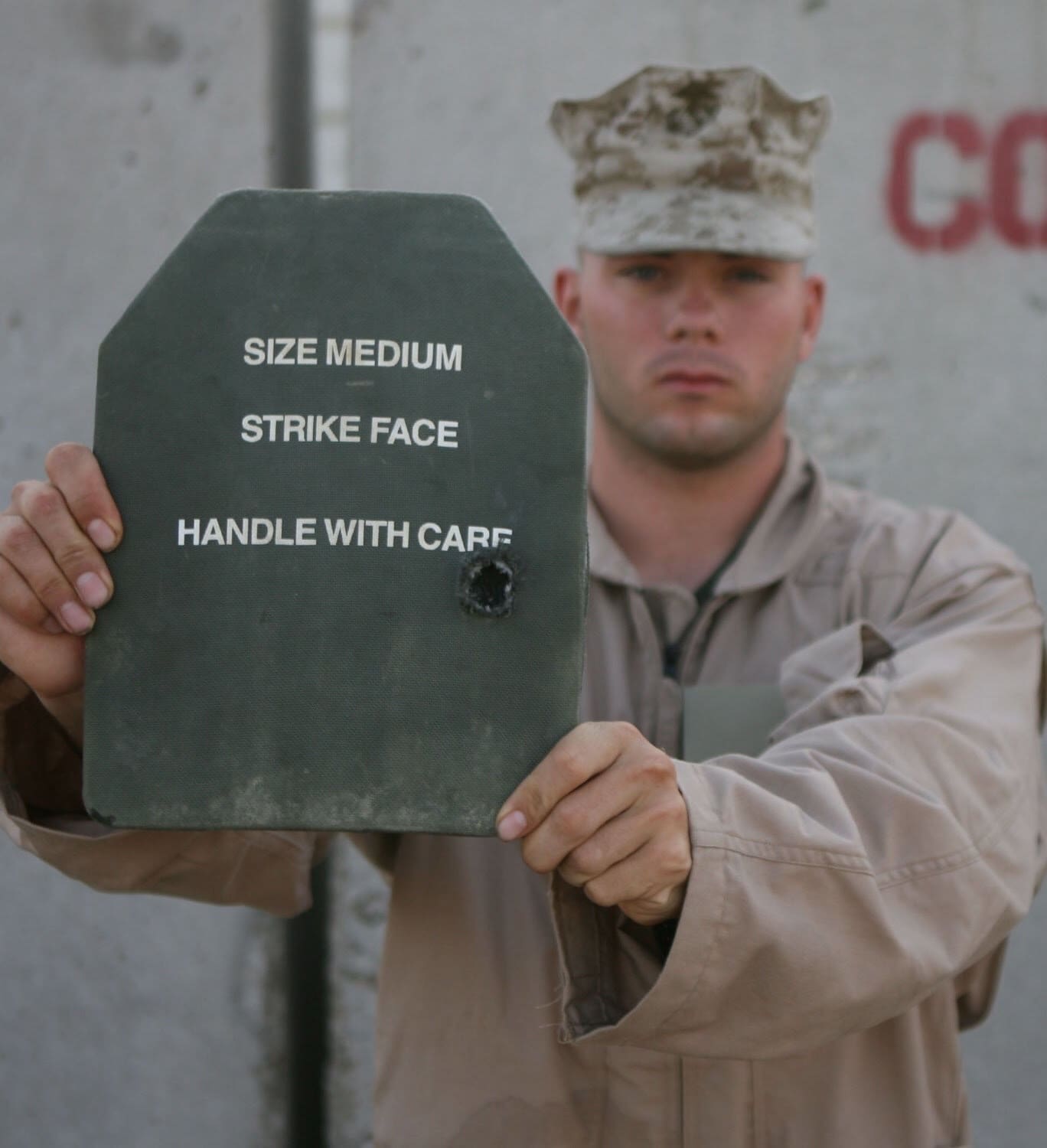

CENTRAL LAKE, MI, October 30, 2018 – Central Lake Armor Express, Inc. (“Armor Express”), a leading manufacturer and distributor of high-performance armor solutions, today announced that it has been awarded a multi-year, firm-fixed-price, indefinite-delivery/indefinite-quantity contract from the Marine Corps Systems Command (Contract #: M67854-19-D-1509). The contract was competitively procured as a total small business set-aside, with a potential value of $59.4 million. Under the terms of the award, the Company will provide up to 65,469 Plate Carrier Generation III – Soft Armor Inserts and data reports, with production expected to be completed by October 2023.

Jim Henderson, Chief Executive Officer of the holding company that owns both Armor Express and KDH Defense Systems stated, “It is our extreme honor to be chosen by the U.S. Marine Corps for this prestigious award, and we thank them for the trust they have placed in us. We also commend ongoing efforts by the U.S. Armed Forces to develop lighter body armor systems, while improving the modularity and flexibility of plate carriers deployed in the field. It is the servicemen and women who ultimately benefit, and all of us at Armor Express and KDH Defense Systems, stand ready to deliver.”

Mr. Henderson added, “With the recent contract extensions KDH received for the Modular Scalable Vest and Blast Pelvic Protection, along with this most recent ballistic protection award for Armor Express, we have secured over $140.0 million of potential business with the U.S. Armed Forces over the past two months. Working in tandem with our supply chain and technology partners, it remains our goal to provide all customers with the most advanced, lightweight and comfortable protection, supported by unparalleled delivery and service.”

The Company intends to leverage the manufacturing capabilities of KDH Defense Systems and will produce the ballistic armor at KDH’s state-of-the-art manufacturing facility in Eden, North Carolina.