The demand for advanced engineered material solutions is ever-present in the rapidly evolving defense and tactical industries. Tactwear®, a product line dedicated to these sectors, continues to innovate and expand, directly responding to feedback and requirements from the field.

Tactwear® AMF – The New Frontier in Tactical Fabrics:

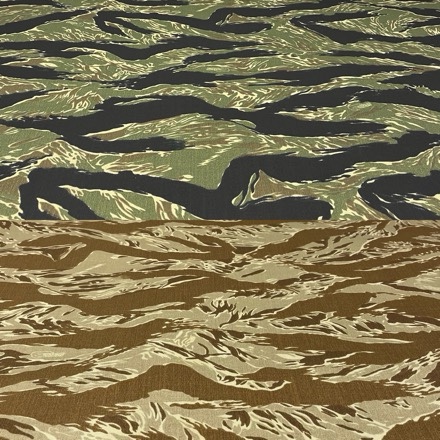

Tactwear® AMF stands out as a significant addition to the Tactwear® range. This product features a composite of one layer of Cordura® 500D nylon and one layer of 1000D tactical nylon, designed to surpass the demanding requirements of modern tactical gear, including the Modular Scalable Vest and Gen III Plate carrier.

Key features of Tactwear® AMF include:

• Superior abrasion resistance

• nIR compliant

• Laser cuttable

• Berry compliant

Tactwear® HANK HALO – Embracing Sustainable Innovation:

Original Tactwear® HANK has been re-engineered into Tactwear® HANK HALO, integrating halogen-free flame-retardant chemistry for better sustainability and REACH compliance.

This reengineered version offers:

• High Abrasion Neoprene Kevlar® Coated Tactical Nylon, available in 1050D, 840D, or 210D

• 30% improved abrasion resistance over its predecessor

• FR (Flame Resistant) and self-extinguishing

• Improved compatibility with laser cutting

• Water and abrasion resistance

• Reduced IR signature

• Berry compliant

Experience Tactwear® at Shot Show 2024:

Attendees can check out the Tactwear® product lineup at the Shot Show Supplier Showcase (booth #51432), scheduled for January 22 and 23, 2024, in Las Vegas, Nevada.

Tactwear® has established a distribution network to cater to a broader range of clients, ensuring accessibility even for those who do not meet the minimum order quantities.

Tactwear®’s ongoing evolution demonstrates its commitment to meeting the dynamic needs of the defense and tactical industries. By integrating field feedback and focusing on innovative development, Tactwear® is responding to current market demands and shaping the future of tactical engineered material technology.

www.trelleborg.com/en/engineered-coated-fabrics/industries/safety/tactwear