Portfolio brands A&E, Burlington, Cone Denim, Gutermann and Safety Components drive meaningful change

Charlotte, NC (September 24, 2019) – Elevate Textiles, a global provider of advanced, high quality products and mission critical textile solutions, announced today its commitment to achieve specific sustainability targets by the year 2025 across its portfolio brands including American & Efird, Burlington, Cone Denim, Gutermann and Safety Components.

Elevate Textiles announced these commitments in conjunction with their exhibiting at the Intertextile Shanghai Apparel Show September 25-27, Booth 4.1-G21, Hall 4.1 National Exhibition and Convention Center.

Elevate brands are committed to achieving sustainability milestones by the year 2025 in three key environmental areas – fibers, water and greenhouse gases.

Elevate’s 2025 commitments are:

-Responsibly sourced fibers –

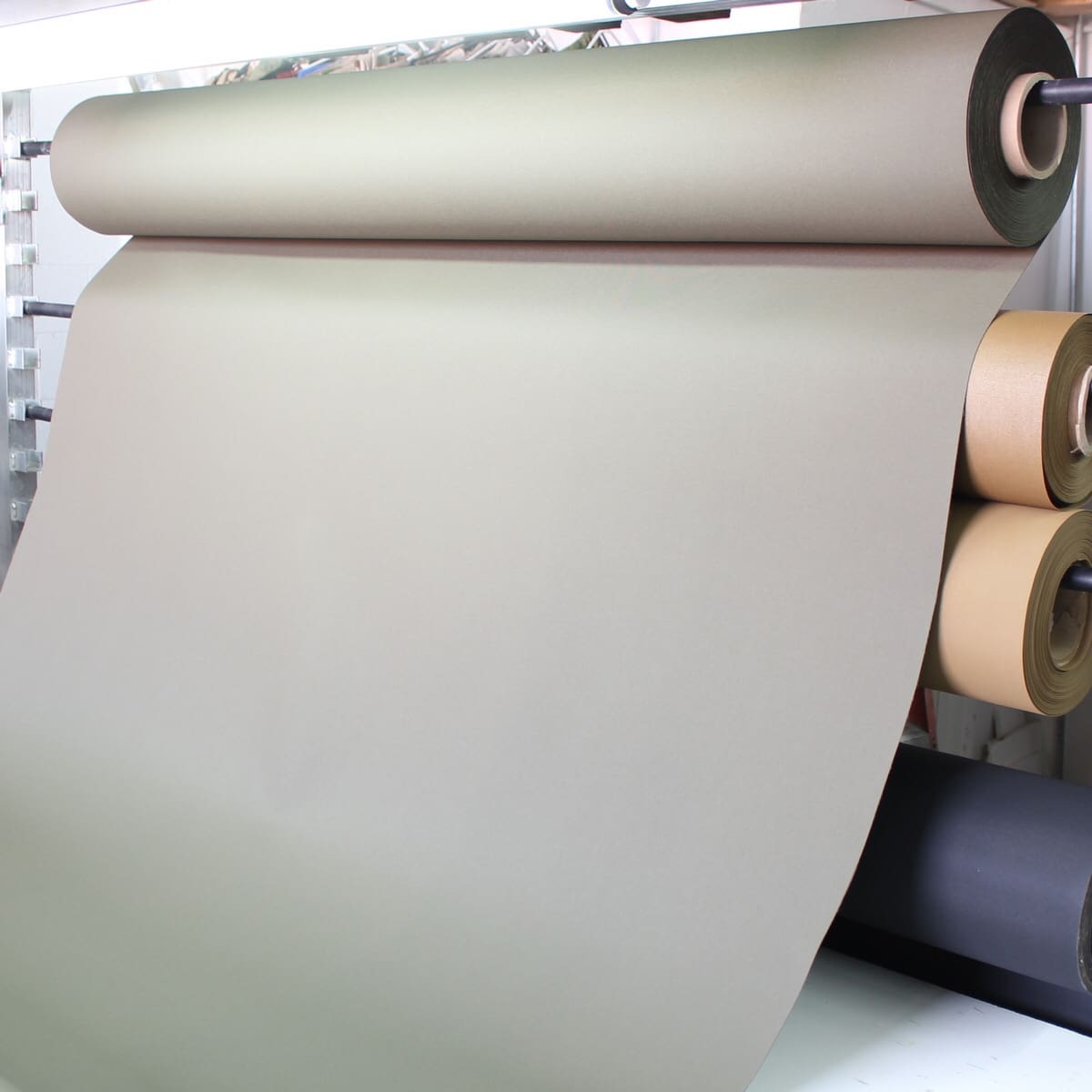

o Elevate brand products will be produced using at least 80% sustainably sourced cotton and 50% recycled polyester content.

-Reduced water consumption-

o Elevate manufacturing operations will reduce its water intensity by 25% per unit of production.

-Reduced greenhouse gases –

o Elevate will join other pacesetters within the industry to join the Science Based Target (SBT) Program and set a specific greenhouse gas target of achieving a 2.5% per year reduction trajectory.

“We are excited to take this next step in the advancement of eco-friendly manufacturing and sustainable products,” says Per-Olof Loof, CEO of Elevate Textiles. “As innovators, our brands are driven to explore new possibilities and look for ways to offer our products with an eye to preserving the future and a focus on minimizing their impact to the environment today, while providing performance technologies and aesthetics that lead the industry. Our 2025 sustainability commitments build on the sustainability improvements we have already attained and solidify our pledge to responsible manufacturing and sustainable innovations fueled by our passion for excellence in all aspects of our operations, products and service to customers.”

Elevate Textiles Vice President Environmental, Health, Safety & Sustainability, Jimmy Summers and Allen Smith, President Burlington, will present and share more details about Elevate’s commitments at Intertextile’s 2020 Sustainability Garment Supply Chain Symposium and panel discussion on September 25th.