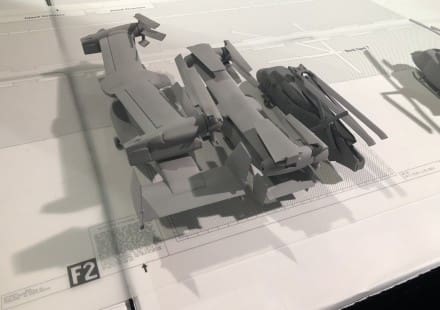

An integrated solution will be showcased detailing Hero Multi-Canister Launcher mounted on an Oshkosh JLTV

MDM, Modern Day Marine Exhibition, Marine Corps Base, Quantico, September 17-19, Stand 1335

September 12, 2019. UVision Air Ltd. – a global leader in the area of Loitering Munition Systems of all sizes for a variety of missions? will present its HERO series of Loitering Munitions at Modern Day Marine for the first time. An integrated solution will be showcased detailing UVision multi-canister launcher mounted on an Oshkosh JLTV (Joint Light Tactical Vehicle).

According to Jim Truxel, CEO of UVision USA and former Marine, “As pioneers in the area of Loitering Munition Systems, UVision is responsive to the rapidly changing needs of modern battlespaces. The company’s solutions are optimized for a variety of platforms, applications and scenarios ? delivering advanced capabilities that ensure combat superiority as well as survivability for even the most complex missions.”

UVision will present the Hero-120, as well as the Hero-30 with multi-canister launcher mounted on an unmanned vehicle, at the company’s stand (#1335) in Modern Day Marine. In addition, an integration of the Hero-120 and Hero-400EC multi-canister launcher mounted on board the Oshkosh JLTV will be on display at the Oshkosh stand (#1703). Once integrated with a HERO loitering weapon system, this fast, agile and powerful Joint Light Tactical Vehicle, with C4ISR capabilities, is the most ideal for complex missions to deploy to the battle. UVision’s Hero-400EC will also be showcased at the US Marine Corps Warfighting Laboratory (MCWL) at the exhibition.

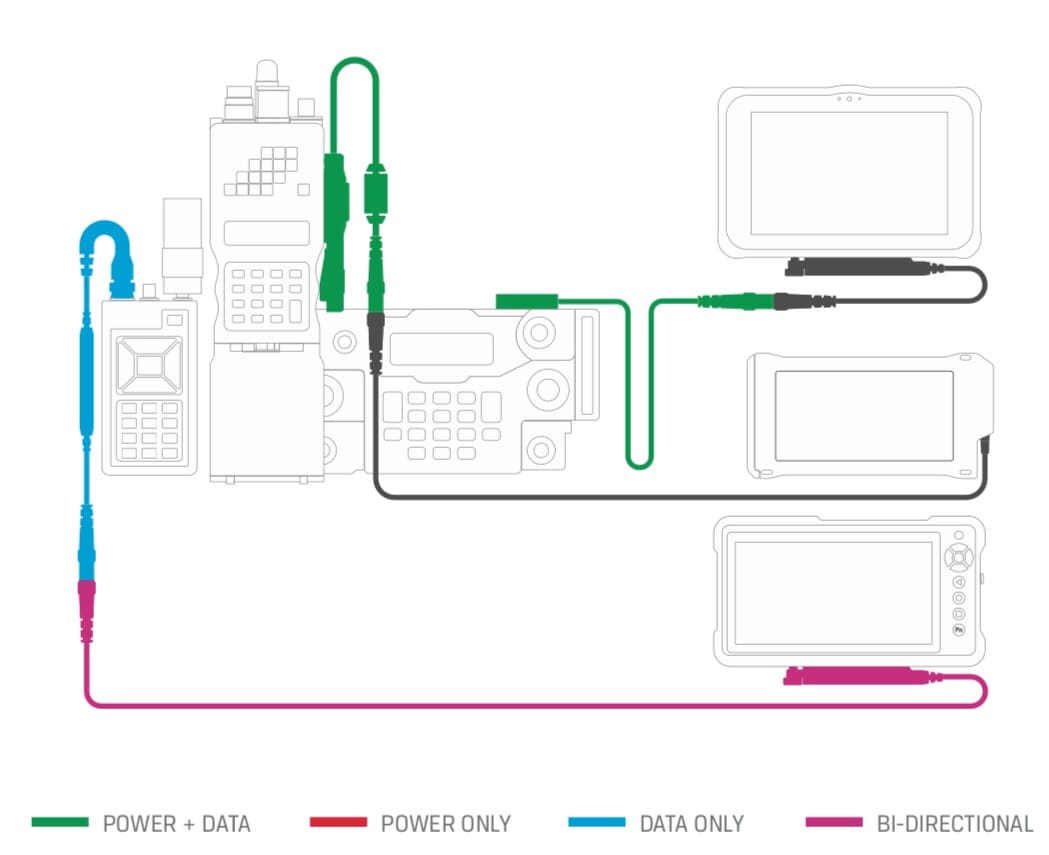

UVision systems are easily adapted to a wide range of maritime, land, and airborne platforms. At MDM, the company will demonstrate its unique advanced yet user friendly Simulator, for MDM attendees to experience through the show.

UVision Air Ltd. took a strategic decision at the beginning of 2019 with the establishment of UVision-USA Corporation. This commitment by UVision to increase it presences in the United States and become a local source for our military customers reinforces UVision’s long-term strategic plan and dedication to support the US Warfighters.